1.Detailed Descriptions

19

sensor [A]. The paper is then shifted for a specified distance. These operations are applied to each

sheet, so that the edge of each sheet is aligned as shown by the blue line above.

Stapler Mechanism

This option uses the crimping method. V-shaped teeth align the paper and press a tooth-mark onto the

paper. This tooth-mark holds the paper together. The pressure applied is 220 kg.

This option performs two stapling movements for every stapling operation.

Moving to the first staple position Stapling Moving to the second staple position

Stapling Moving back to the home position

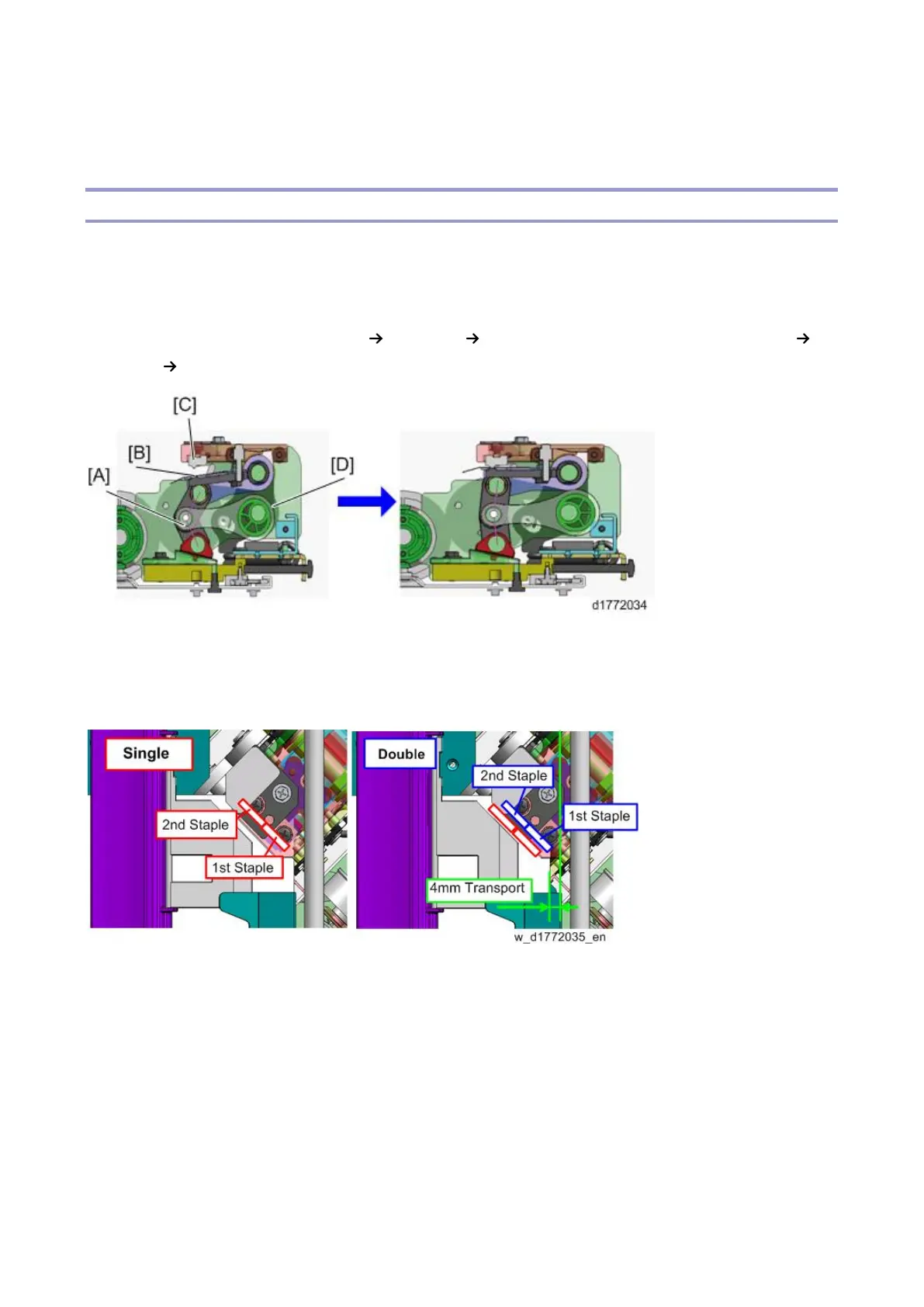

The pressure cam [D] stretches the pressure link [A], and the upper tooth [C] and the lower tooth [B] fit

into each other. Stapler movements and stapling operations are driven by the stapler drive motor. The

stapler drive HP sensor detects the home position.

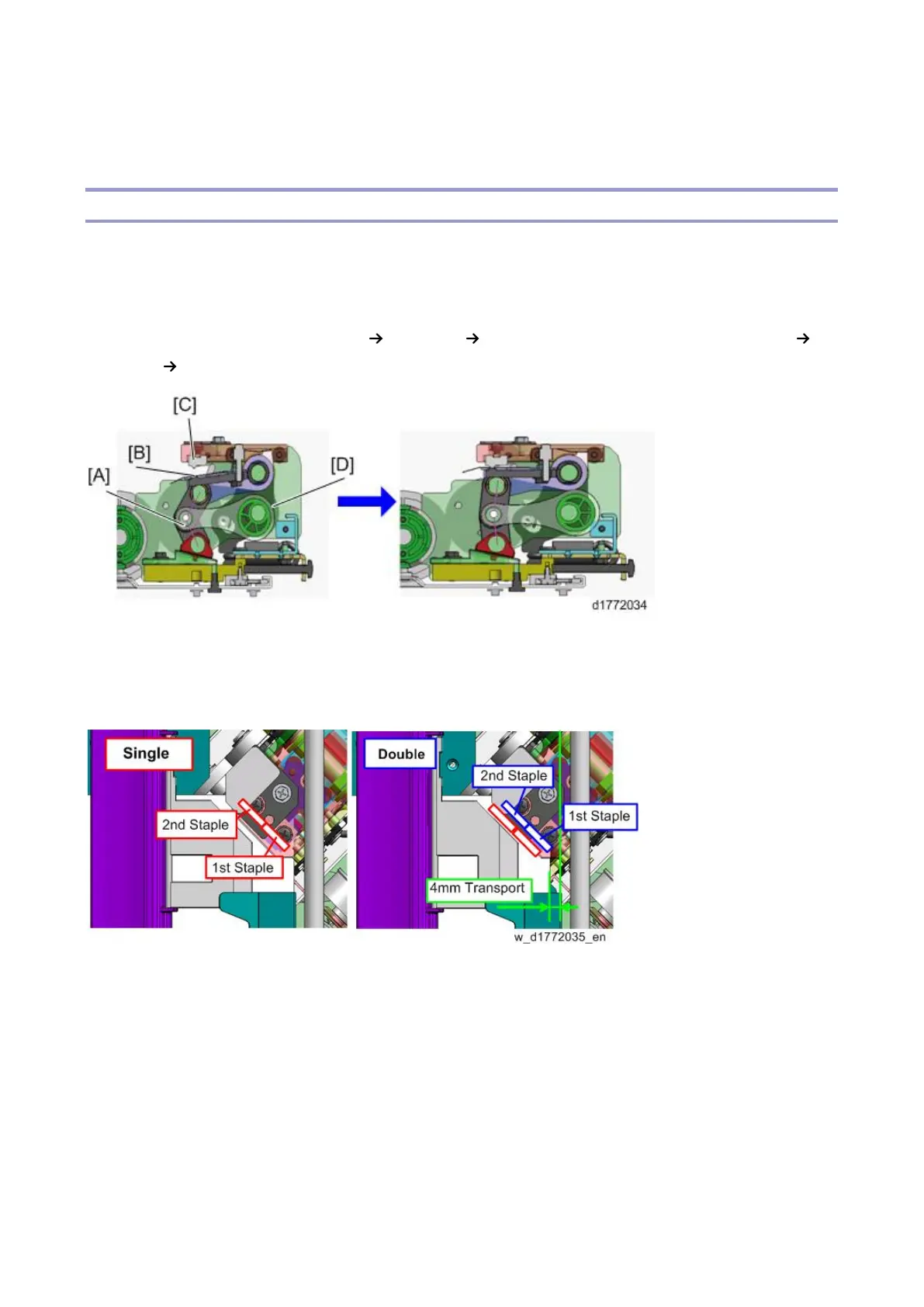

• Double/Single Staple

It is difficult to adjust the bonding strength because it depends on how well the paper fibers twine.

Setting to Single or Double allows you to adjust the bond strength.

For Single, stapling is applied twice.

For Double, after stapling is applied twice, the paper exit roller shifts the paper 4mm, and a stapling

operation is applied again.

• Paper exit

After stapling, the trailing edge presser is released. The paper exit rollers ejects the paper.

Loading...

Loading...