4040+e_22.docx / 06.10.17

ROBERT RIELE GmbH & Co KG Page 64 10 - ERROR MESSAGE / CORRECTION

10 ERROR MESSAGE / CORRECTION

10.1 GENERAL NOTE

Faulty input (e.g. wrong method number or wrong factor), recognized by the user, can be corrected by filling up

the respective entry field with any signs. After replenishing beyond the last position the faulty input is deleted and

the entry field is free again for the renewed correct input.

Error messages by the device are carried out either exclusively via a signal tone (chapter 10.2 - ACOUSTIC

ERROR MESSAGES) or as combination signal tone and display.

In the display errors are shown as plaintext (chapter 10.3 - PLAINTEXT ERROR MESSAGES)

… or coded with an error number (chapter 10.4 - CODED ERROR MESSAGES).

Each error message has always to be confirmed with [E].

10.2 ACOUSTIC ERROR MESSAGES

When pressing a key which is not permitted or not meaningful a deeper signal tone still sounds as error message

after the higher signal tone (which is to confirm the keystroke, can be switched off according to chapter 8.2.13 -

Key signal ON / OFF). In the display no corresponding error message appears parallel to this. The operation of

the device can directly be continued by the correct keyboard entry.

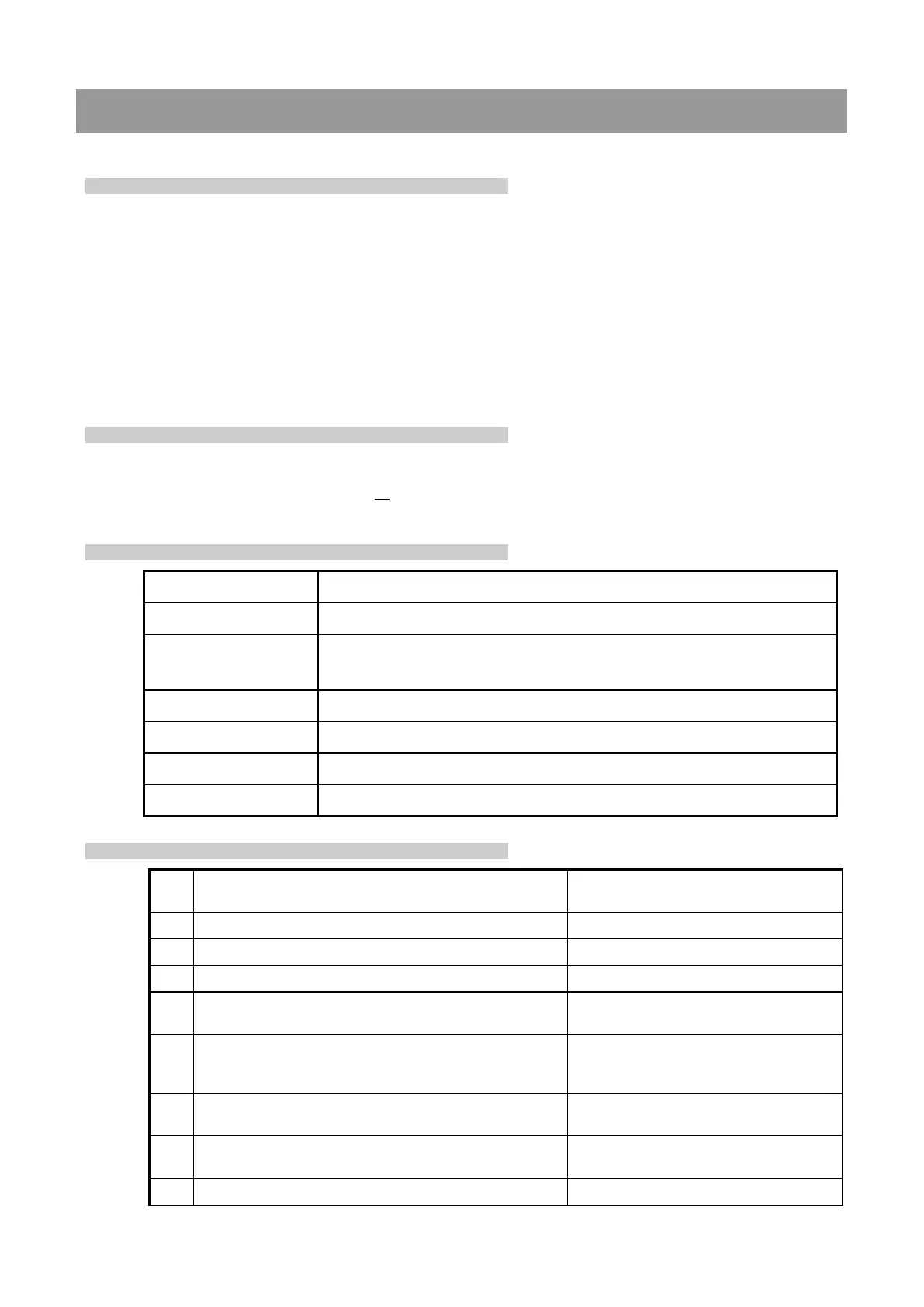

10.3 PLAINTEXT ERROR MESSAGES

The programmed low limit was under-run by the measurement.

The programmed upper limit was exceeded by the measurement.

The square of the correlation coefficient r lies at the kinetic measuring below the

programmed low limit.

At the kinetic measuring the procedure of the kinetic is wrong (increasing / falling).

Dialed method is not programmed. Select other method according to method list.

Heating / cooling is off during temperature calibration.

Temperature is unstable during temperature calibration.

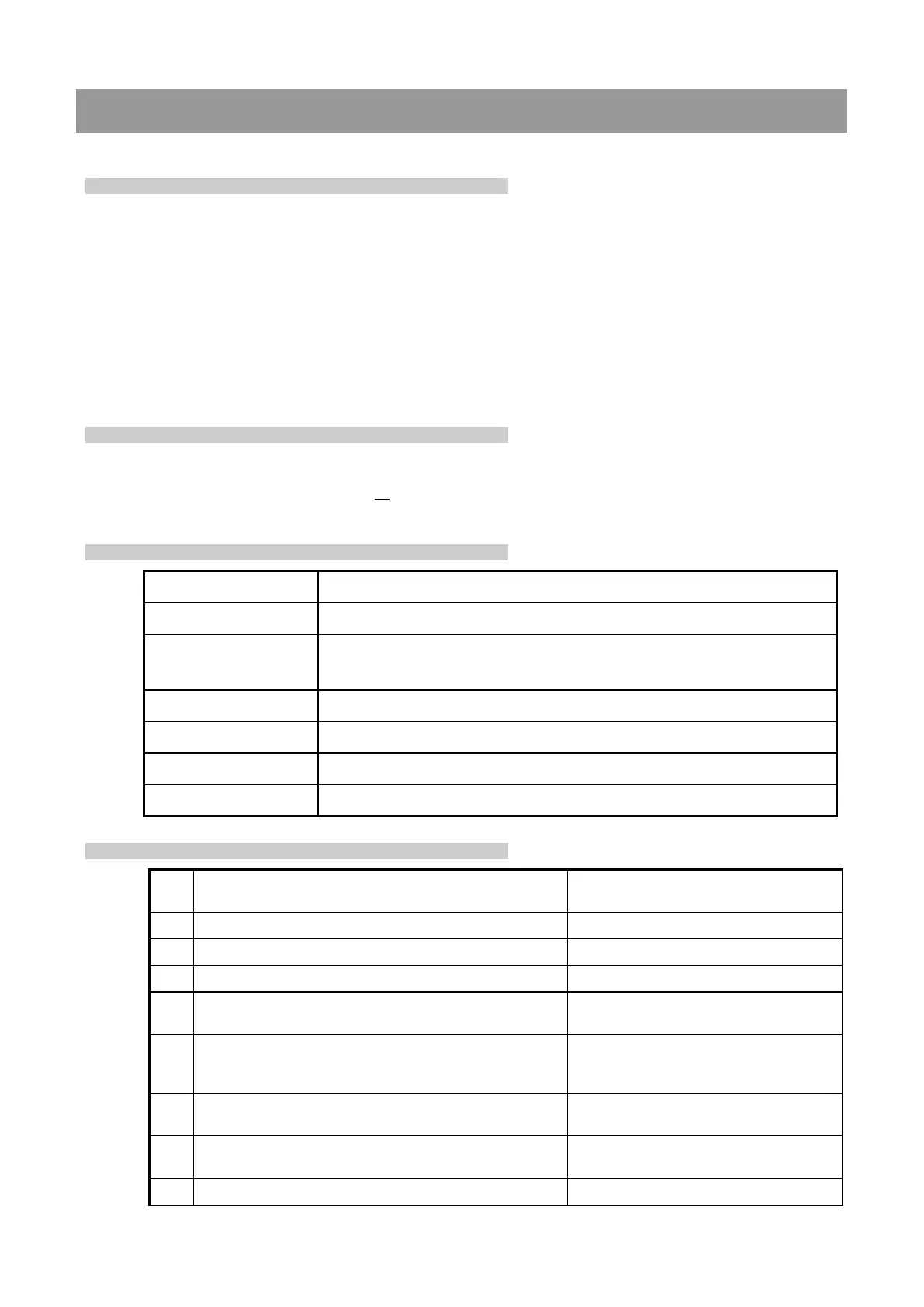

10.4 CODED ERROR MESSAGES

method is write protected, method cannot be cleared

check sum of a freely programmed method is wrong

forbidden input, wrong number format

repeat input in permitted area

method editor:

check method no.

dark value is absolutely too high (> 16 bit) or higher as the

measurement,

ADC overflow

repeat optic adjustment (chapter 8.2.1);

check LED / filter; check blank

all multiplexer positions are too bright/too dark at setting to

zero

repeat optic adjustment (chapter 8.2.1);

check filter / LED; check blank

mathematical overflow, at measurement calculation

check filter; check standard;

check measuring solution

check sum error in the data record of the dark offset

repeat optic adjustment (chapter 8.2.1)

Loading...

Loading...