27

20152192

Installation

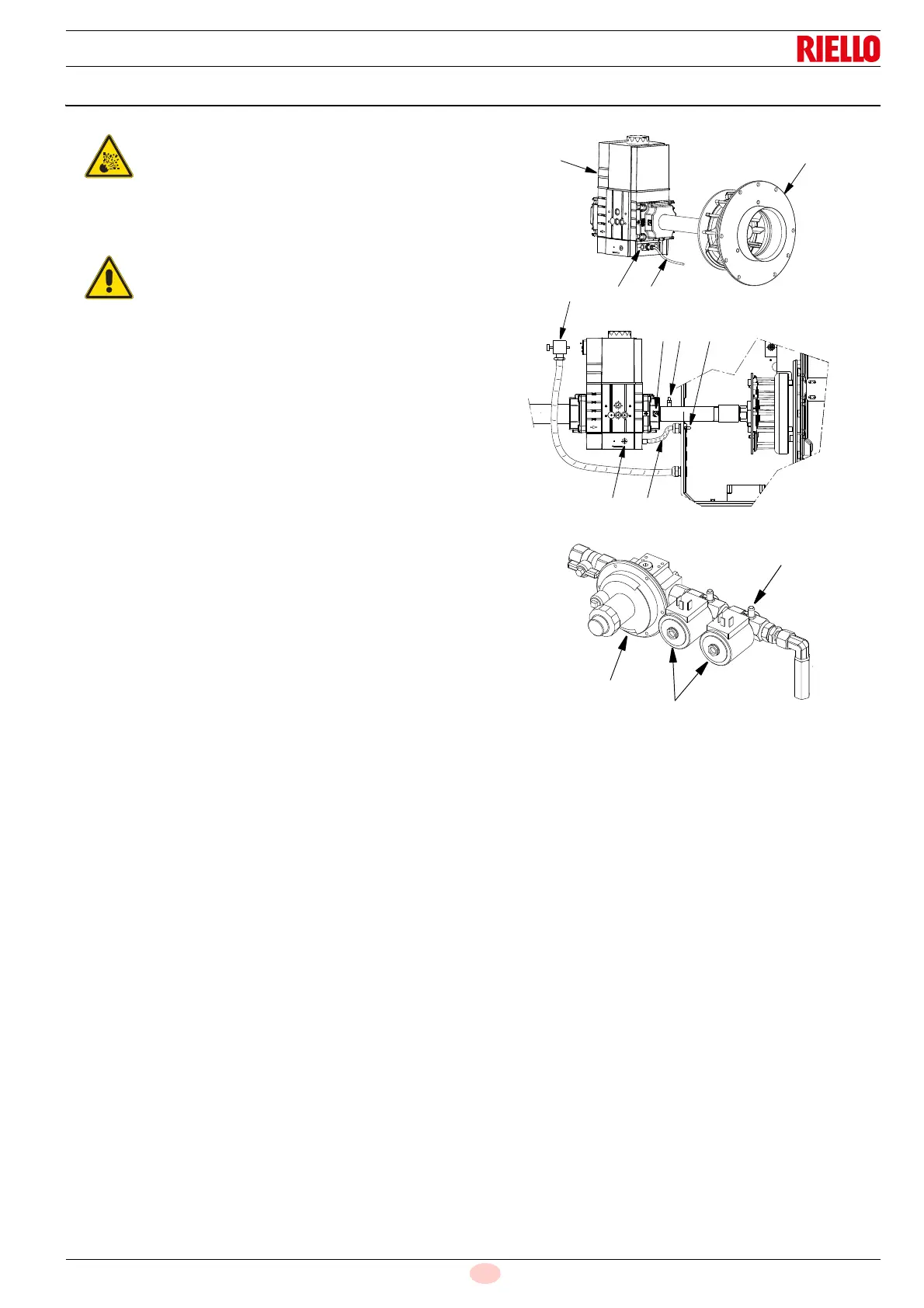

5.7 Fuel supply

The burners are teamed with one-piece pneumatic proportioning

gas valves, via which the amount of gas delivered, and hence the

output produced, can be modulated.

A signal reporting pressure detected in the air circuit is carried to

the pneumatic gas valve, which delivers an amount of gas in pro-

portion to the airflow produced by the fan.

Air/gas mixer

Gas and combustive air are mixed inside the purging circuit (mix-

er), starting from the intake inlet.

Through the gas train, fuel is introduced into the intake air current

and optimal mixing commences with the aid of a mixer.

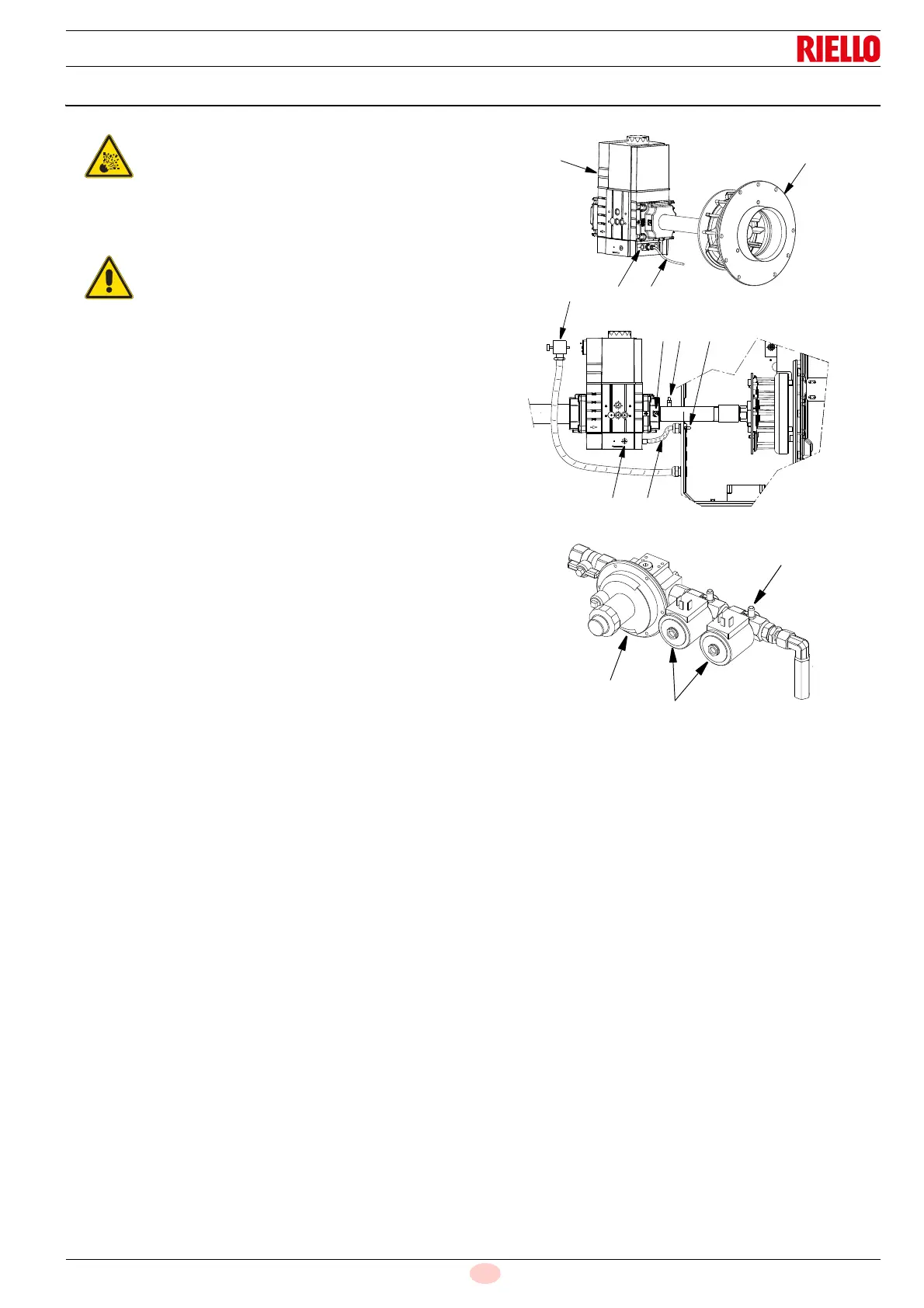

The compensation pipe 3)(Fig. 25) allows compensation to

occur for accidental blockage of the suction line due to a re-

duction in the gas delivered.

Key (Fig. 25)

1 Gas valve

2 Quick coupling

3 Compensation pipe (T)

4 Air/gas mixer in the circuit of the suction line

5 Electronic valve connection (XV1)

6 Maximum gas flow adjustment (V1)

7 Downstream pressure test point

8 Minimum gas flow adjustment (V2)

9 Metallic protective device

10 Pilot supply pressure

11 Pressure adjuster

12 Safety valves

Explosion danger due to fuel leaks in the pres-

ence of a flammable source.

Precautions: avoid knocking, attrition, sparks and

heat.

Make sure the fuel interception tap is closed be-

fore performing any operation on the burner.

The fuel supply line must be installed by qualified

personnel, in compliance with current standards

and laws.

Loading...

Loading...