8 Rockwell Automation Publication MOTION-AT007A-EN-P - May 2020

Chapter 1 DC-bus Wiring Guidelines

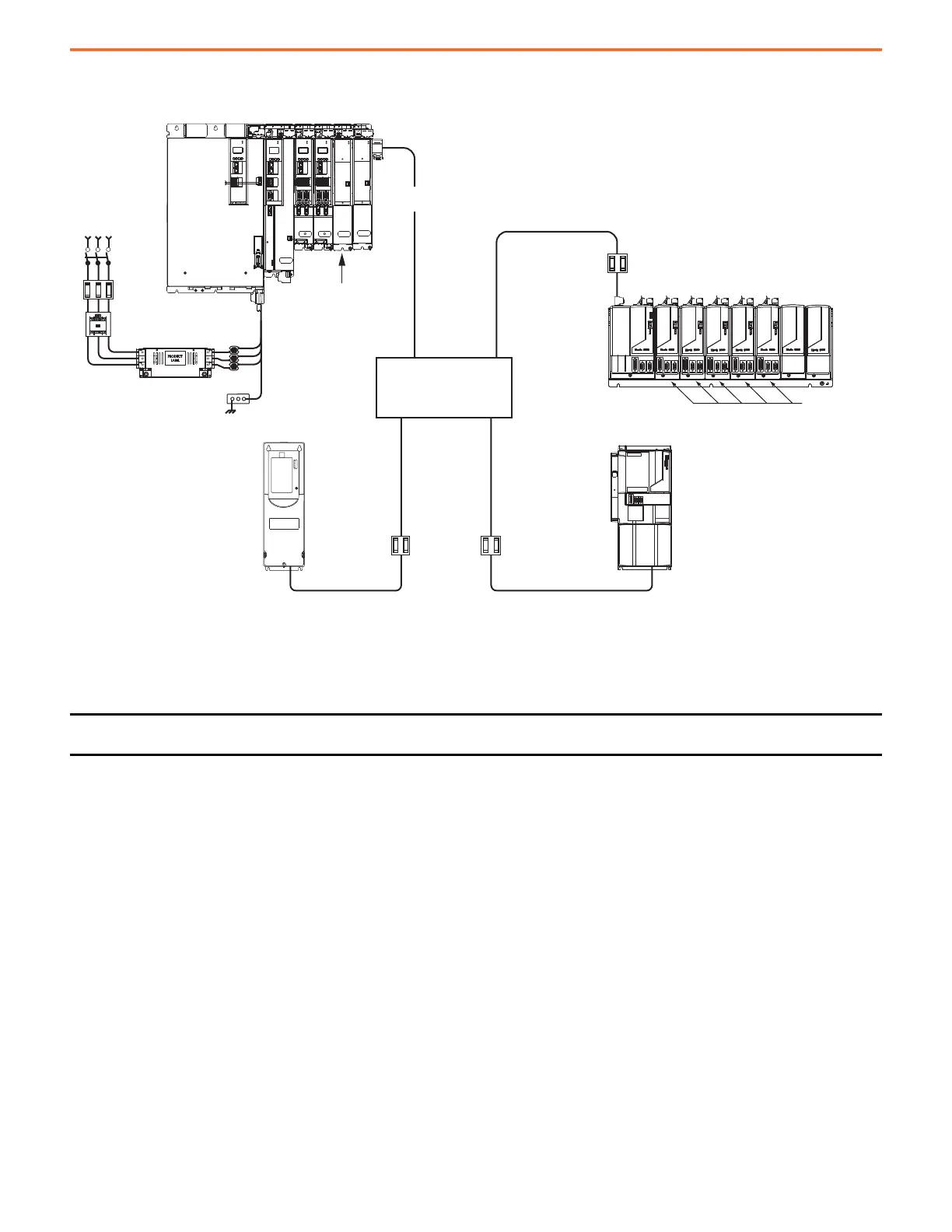

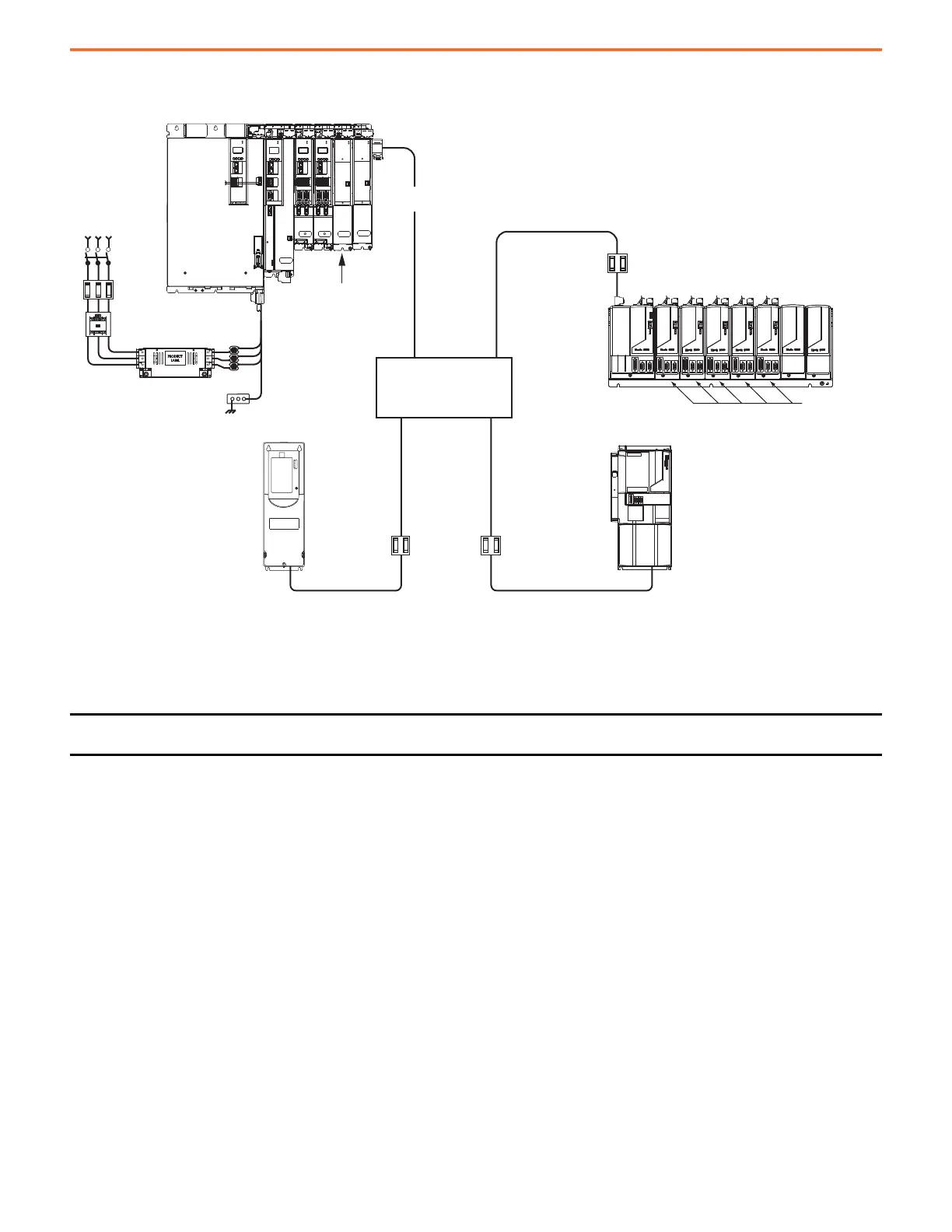

Figure 1 - Extended DC-bus Installation Example

DC-bus Connections

DC-bus cables and bus bars are used to connect drives in common-bus configurations.

DC-bus Cable

When using cables to connect drives to the system bus, observe the following guidelines:

• Use only unshielded cable for DC-bus voltage.

• Use 1000V rated insulation cable in this application.

• Make the DC+ and DC– cable distance as short as possible to help reduce cable inductance.

• Twisting the DC-bus cable together is not required, however, it is recommended to make sure the DC cables are routed close to each

other.

• The maximum DC-bus cable length (power supply cluster to extended cluster) is 70 m (230 ft).

• No single external DC-bus connection from the power supply cluster can exceed 70 m (230 ft). You can extend the DC-bus from the

right and left of the power supply cluster, but the total DC-bus length (including DC-bus cabling and DC bus-bar) from the power supply

cluster to all extended clusters cannot exceed 140 m (459 ft).

• The Bus Voltage Reference Source is configurable. When it is set to Automatic, the converter optimizes the Bus Voltage Reference for

the best converter setting. When it is set to Manual, you configure the desired Bus Voltage Set Point value for the Bus Voltage

Reference signal.

• To prevent nuisance bus-overvoltage faults, the maximum Bus Voltage Set Point of the regenerative bus supply reduces linearly from

750V DC to 715V DC as the DC-bus cable length per cluster increases from 0 to 70 m (230 ft) respectively.

IMPORTANT The interconnection of drives to the DC-bus, and the inductance levels between the drives, must be kept to a minimum for

optimum system operation.

MOD

NET

MOD

NET

MOD

NET

2

1

2

1

2

1

UFB

UFB-A UFB-B

UFB-A UFB-B

D+

D-

D+

D-

D+

D-

MF-A MF-B MF-A MF-B

D+

D-

MBRK

+

-

MOD

NET

D+

D-

MF

MODULE

STATUS

1

I/O-A

6

510

1

I/O-B

6

510

1

I/O

6

5

10

1

I/O-A

6

510

1

I/O-B

6

510

MOD

NET

2

1

1

I/O

6

5

10

OK+

OK–

EN–

EN+

MOD

DC BUS

Single-axis

Inverter

Dual-axis

Inverters

Bulletin 1321

Line Reactor

AC Line Filter

Circuit

Protection

Magnetic (M1)

Contactor

Line

Disconnect

Device

DC-bus Circuit

Protection

DC-bus Circuit

Protection

2094-BMxx-S

Axis Modules (5)

PowerFlex

750-Series AC Drive

2094-BMxx-Mxx-S

IAM Module

Common Bus Follower

2094-PRSx

Power Rail

DC-bus

Extension

Bonded Cabinet

Ground Bus

Kinetix 7000

Servo Drive

Bulletin 1492 Power Distribution

Terminal Block

Kinetix 6000 Servo Drive System

Kinetix 5700

Servo Drive System

Regenerative

Bus Supply

2198-CAPMOD-2240

Capacitor Module

2198-DCBUSCOND-RP312

DC-bus Conditioner Module

2099-BMxx-S

Servo Drive

DC-bus Circuit

Protection

Accessory

Modules

Loading...

Loading...