88 Rockwell Automation Publication 20D-PM001D-EN-P - March 2019

Chapter 2 Programming and Parameters

No. Name

Description

Values

Linkable

Read-Write

Data Type

502 Rotor Resistance

Displays rotor resistance, as determined by the auto-tune procedure. Scaled to percent of rated motor

impedance. Do not change this value.

Default:

Min/Max:

Units:

Scale:

1.00

0.00/100.00

%

100 = 8192

RW 16-bit

Integer

503 Current Reg BW

Sets the bandwidth for the current regulator. Par 402 [PWM Frequency] limits the maximum value. Reducing

the value reduces current regulator over-shoot.

Default:

Min/Max:

Units:

600

100/30000

rad/s

RW 16-bit

Integer

504 PM AbsEncd Offst

Determined by auto-tune procedure.

Default:

Min/Max:

0

0/65535

RW 16-bit

Integer

505 PM TestWait Time

Defines the time interval used for the automated measurement of Par 504 [PM AbsEncd Offst] for a Permanent

Magnet (PM) motor.

Default:

Min/Max:

Units:

2000

500/5000

ms

RW 16-bit

Integer

506 PM Test Idc Ramp

Defines the ramp rate of the Flux Producing (d-axis) current reference that is used for the automated

measurement of Par 504 [PM AbsEncd Offst] for a Permanent Magnet (PM) motor.

Default:

Min/Max:

Units:

Scale:

0.1

0.0/195.3

%/ms

x 10

RW 16-bit

Integer

507 PM Test FreqRamp

Defines the ramp rate of the frequency reference that is used for the automated measurement of Par 504 [PM

AbsEncd Offst] for a Permanent Magnet (PM) motor.

Default:

Min/Max:

Units:

Scale:

0.1

0.0/195.3

%/ms

x 10

RW 16-bit

Integer

508 PM Test Freq Ref

Defines the frequency reference that is used for the automated measurement of Par 504 [PM AbsEncd Offst] for

a Permanent Magnet (PM) motor.

Default:

Min/Max:

Units:

Scale:

10.0

-/+799.9

%

x 10

RW 16-bit

Integer

509 PM Test I Ref

Defines the amplitude of the Flux Producing (d-axis) current reference that is used for the automated

measurement of Par 504 [PM AbsEncd Offst] for a Permanent Magnet (PM) motor.

Default:

Min/Max:

Units:

Scale:

30.0

0.0/799.9

%

x 10

RW 16-bit

Integer

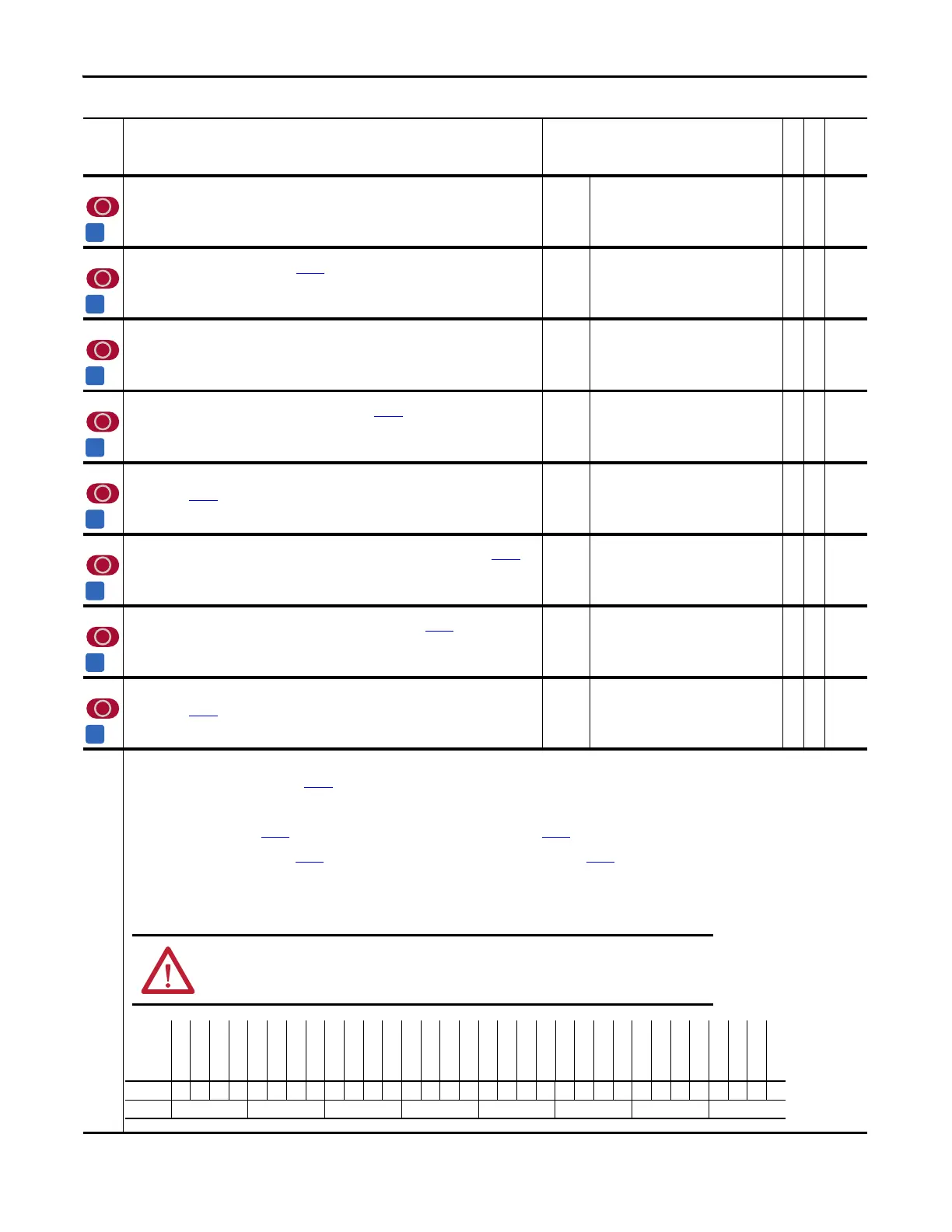

510 FVC Mode Config

Configures Field Oriented Control (FOC) operation.

• Bit 4 “SlipTuneDone” when set, the value in Par

486 [Rated Slip Freq] is used as the slip gain before the slip regulator becomes active, after power is cycled, or when the drive is reset by the

system. When the Slip Tune is completed, this bit will be automatically be set and Par 486 will be updated.

• Bit 7 “Ids Comp En” setting this bit runs the Ids test, to establish the initial flux current level for the motor, and the inertia test (even if already run).

• Bit 12 “SlipRsCompEn” when set, the stator resistance will be compensated based on the output of the slip regulator.

• Bit16 “ManuCurOffst” when set, Par

453 [Iu Offset] is used as the phase U current feedback offset value and Par 454 [Iw Offset] is used as the phase W current feedback offset value. When this bit

is not set (default) the phase U and W current feedback offset values are automatically updated when the drive is in a stop condition except during the first 10 seconds of the stop condition.

• Bit17 “ManuVltOffst” when this bit is set, Par

549 [Vuv Fdbk Offset] is used as the UV voltage feedback offset value and Par 550 [Vvw Fdbk Offset] is used as the VW voltage feedback offset value.

• Bit 23 “SyncTrans En” when set (default), the synchronous transfer algorithm using voltage feedback data is active.

• Bit 26 “SlipGnLimAct” when set = 0 (default), set slip regulator output (SlipGain) to latched SlipGain. When set =1, set SlipGain to Max SlipGain when SlipGain is in Max SlipGain limit, or set

SlipGain to Min SlipGain when SlipGain is in Min SlipGain limit.

Notes: Bit changes were made for firmware version 2.003. Bits 10 and 11 were added for firmware version 3.001. Changed bit 3 from “Reserved” to “FastFluxDsbl” for firmware version 3.003. Added

bits 4, 7, 12, 16, 17, and 23 for firmware version 4.001. Added Bit 26 for firmware version 6.001.

ATTENTION: Do not modify this parameter. Motor/Drive instabilities and damage may result.

Options

Reserved

Reserved

Reserved

Reserved

Reserved

SlipGnLimAct

Reserved

Reserved

SyncTrans En

SrLss RdThru

VltMinorLpEn

SoftAdptGain

Reserved

Reserved

ManuVltOffst

ManuCurOffst

LwSpdRflctWv

Slip Reg En

SlipGain Est

SlipRsCompEn

SlipPrloadEn

SlipSlewRtEn

ReflWaveComp

BusGain Comp

Ids Comp En

Flux Reg Use

Flux Reg En

SlipTuneDone

FastFluxDsbl

Reserved

Reserved

Reserved

Default xxxxxxxx1010xx000110001101100xxx

Bit 313029282726252423222120191817161514131211109876543210

0 = False

1 = True

Loading...

Loading...