Reference Manual

00809-0100-4021, Rev FB

August 2011

Rosemount 3144P

2-6

INSTALLATION

Typical North American

Installation

1. Attach the thermowell to the pipe or process container wall. Install and

tighten thermowells and sensors, then apply process pressure to perform

a leak test.

2. Attach necessary unions, couplings, and extension fittings. Seal the

fitting threads with PTFE tape (if required).

3. Turn the sensor into the thermowell or directly into the process

(depending on installation requirements).

4. Verify all sealing requirements for severe environments or to satisfy code

requirements.

5. Attach the transmitter to the thermowell/sensor assembly. Seal all

threads with PTFE tape (if required).

6. Pull sensor leads through the extensions, unions, or couplings into the

terminal side of the transmitter housing.

7. Install field wiring conduit to the remaining transmitter conduit entry.

8. Pull the field wiring leads into the terminal side of the transmitter housing.

9. Attach the sensor leads to the transmitter sensor terminals. Attach the

power leads to the transmitter power terminals.

10. Attach and tighten both transmitter covers since both transmitter covers

must be fully engaged to meet explosion-proof requirements.

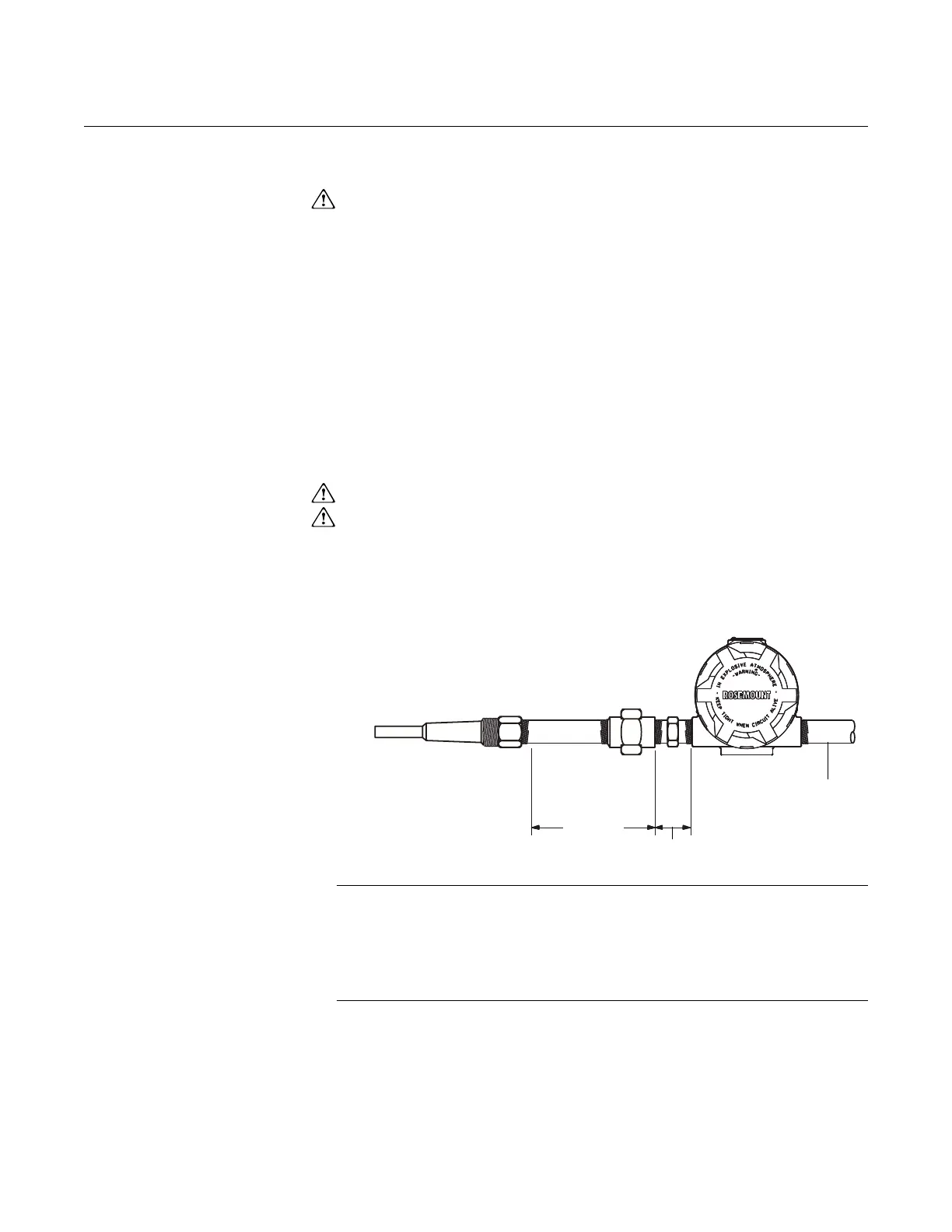

Figure 2-4. Typical North

American Mounting

Configuration

NOTE

The National Electrical Code requires that a barrier or seal be used in addition

to the primary (sensor) seal to prevent process fluid from entering the

electrical conduit and continuing to the control room. Professional safety

assistance is recommended for installation in potentially hazardous

processes.

Thermowell

Extension

Conduit for Field

Wiring (dc power)

3.2

(81)

Extension

Fitting

Length

Union or

Coupling

NOTE: Dimensions are in inches (millimeters).

Loading...

Loading...