d05398.fm

INSTALLATION MANUAL

BRP-Powertrain

Effectivity: 912 i Series

Edition 1/Rev. 0

79-00-00

Page 12

January 01/2012

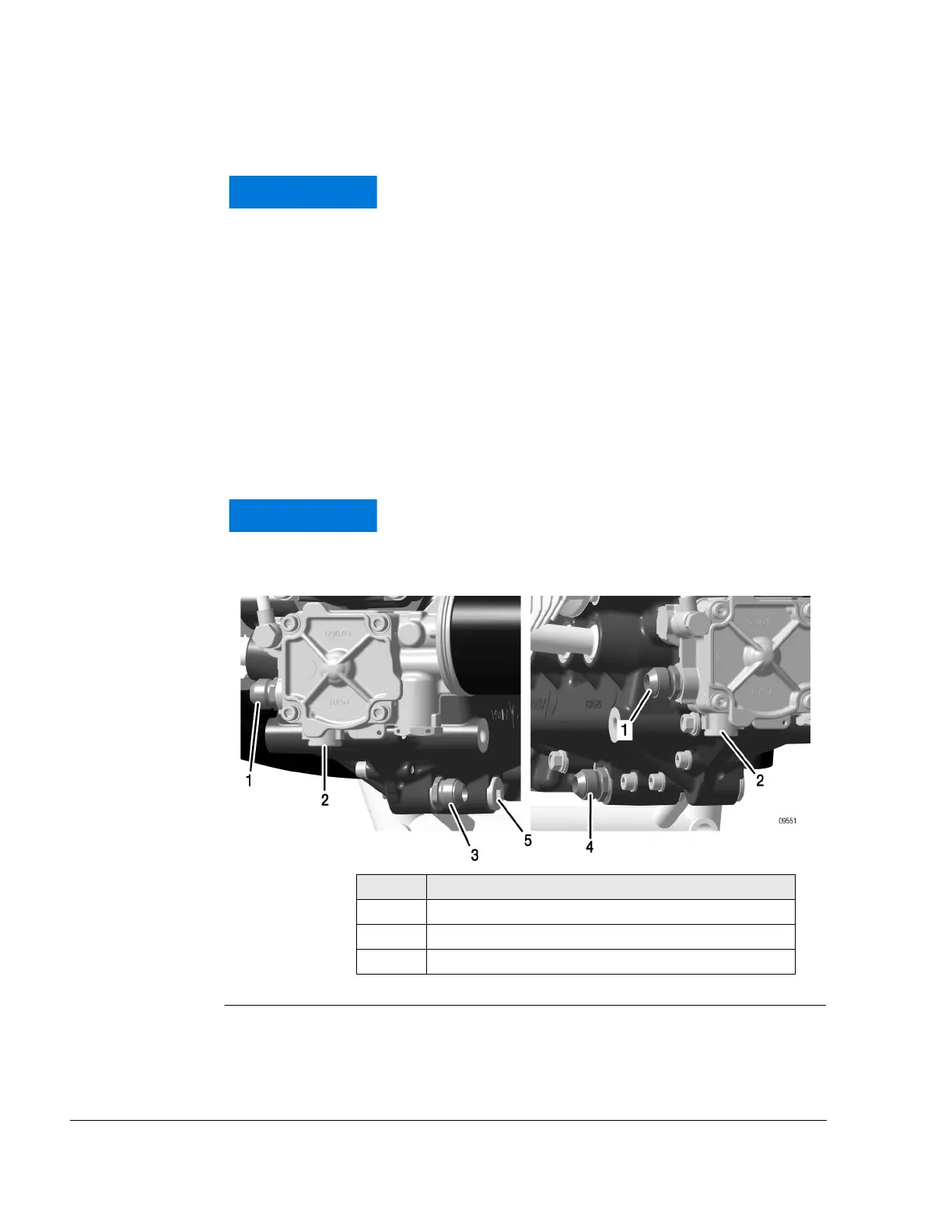

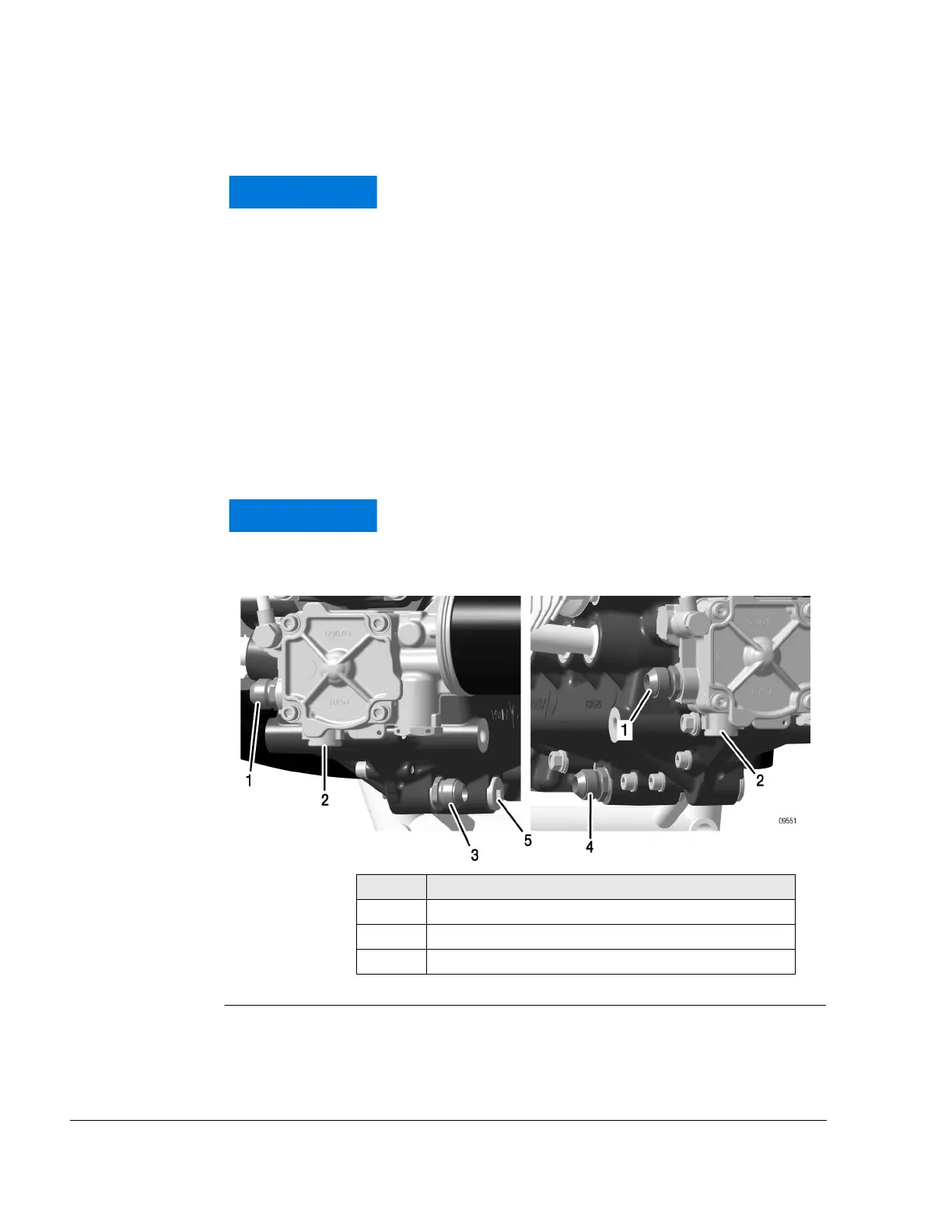

Oil return

See Fig. 7.

Select the appropriate connection for the oil return line according to the

propeller configuration and oil system layout.

- Position 4, 5 for tractor arrangement

- Position 3 for pusher arrangement

Graphic Connections

Fig. 7

The engine design is for a conventional, non-aerobat-

ic, tractor or pusher configuration with the oil return

port in the optimum position. Assuming these points

are taken into consideration, the engine will be prop-

erly lubricated in all flight profiles. Aircraft that are not

conventional (e.g. airships, gyrocopters, dive brake

equipped aircraft, etc.) that require engine load at

steep inclination angles may have special lubrication

requirements.

Check that the connections for the oil feed and return

lines are correct.

Part Function

1 or 2 Screw socket (oil feed line) from oil tank or oil cooler

3 Screw socket (oil return line) for pusher arrangement

4 or 5 Screw socket (oil return line) for tractor arrangement

Loading...

Loading...