90

.

July 2014

.

IMO_347_EN_v0 Roto NT Subject to change.

Operation

Troubleshooting

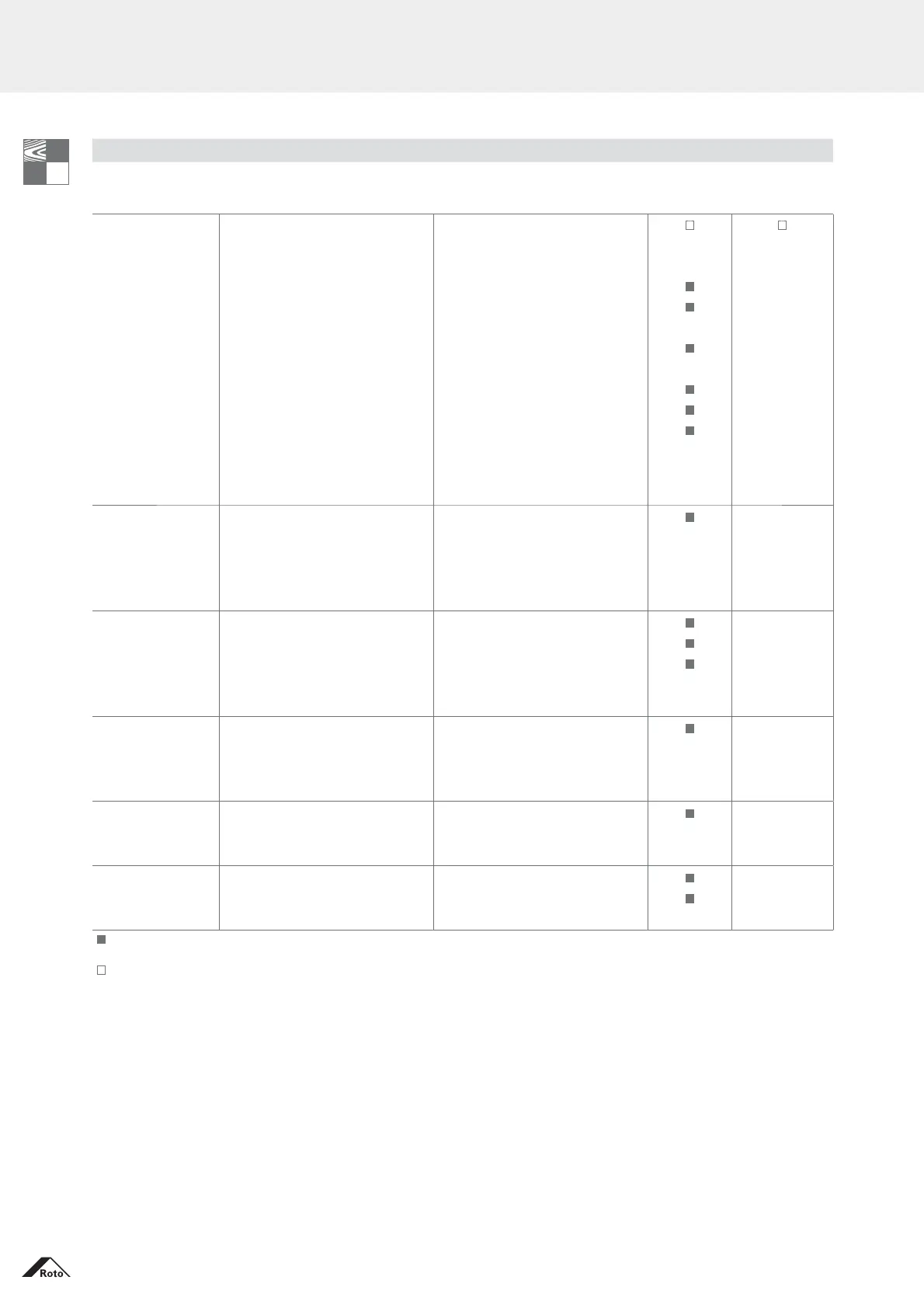

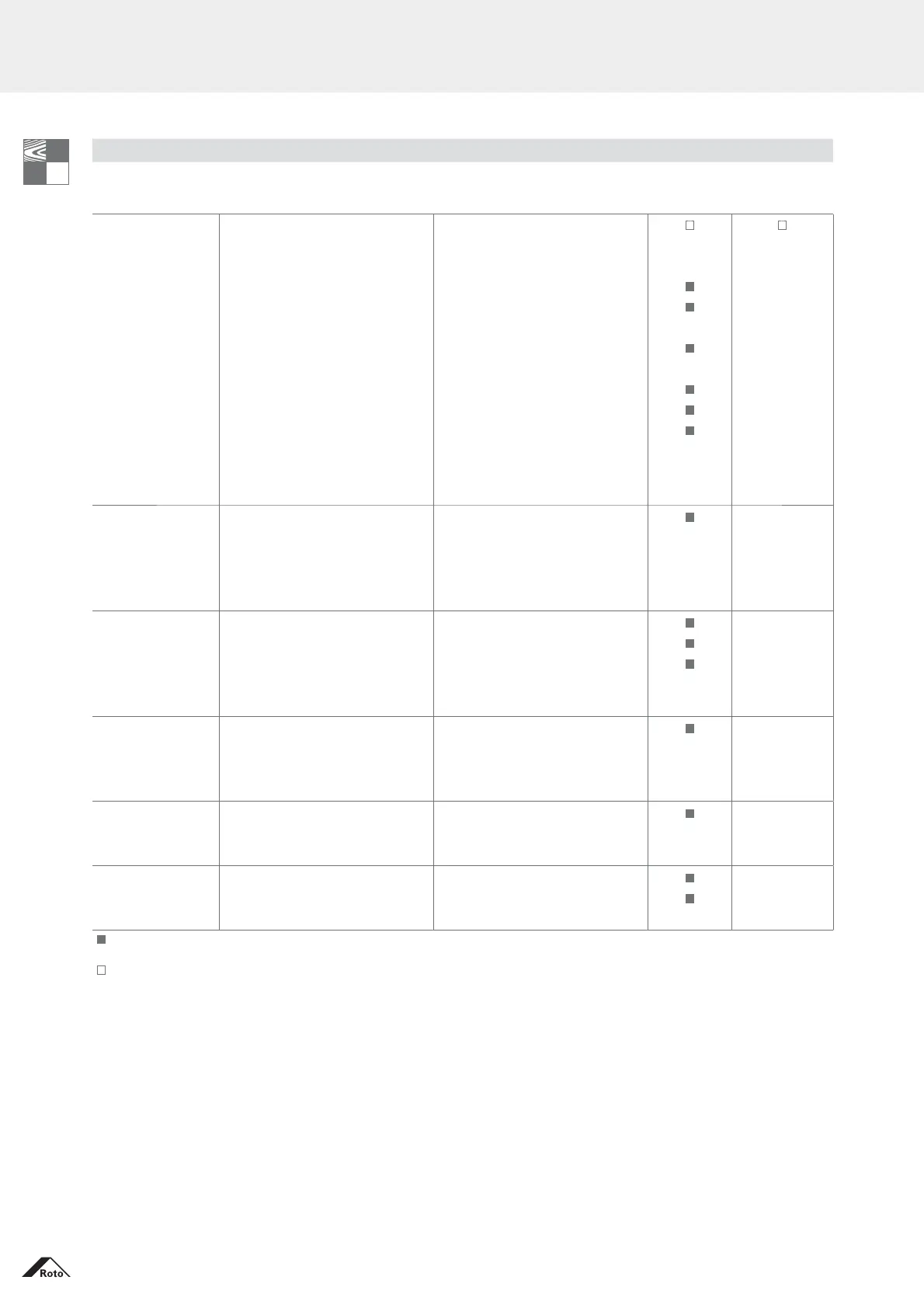

Troubleshooting

Problem Cause Corrective action

Specialist

company

End-users

Handle is difficult

to rotate.

– Frame parts are not properly

greased.

– Faulty

handle.

– Handle screws are screwed

intoo strong.

– Oblique screws in the sash

parts.

– Faulty sash parts.

– Faulty striker locations.

– Sash stay gasket compression

too strong (accumulation of

gaskets).

– Grease frame parts.

– Replace the handle.

– Slightly loosen the screws.

– Straight screw-fixing of the

sash parts.

– Replace the sash parts.

– Adjust the striker locations.

– Adjust or reduce the sash stay

gasket compression.

–

–

–

–

–

–

Handle can not

rotate 180°.

– Faulty hinging or installation

ofsash parts.

– Check adjustment in turn

position (if necessary, rehinge

the sash proceeding from

T&Tespagnolette).

–

In turn mode, the

sash falls into

tilted position.

– Too much clearance on top. – Check corner hinge location.

– Check pivot rest location.

– Raise the corner hinge.

(Attention: tilt striker)

–

–

–

In tilt mode, the

sash falls into

turning position.

– Faulty

tilting component.

– Replace

tilting component.

–

Sash is rubbing

intilt mode.

– Insufficient clearance on top. – Lower the corner hinge.

(Attention: tilt striker!)

–

Locking cams

rubber at striker.

– Faulty hinging of the sash.

– Faulty striker locations.

– Hinge the sash once again.

– Adjust the striker locations.

–

–

= To be carried out only by a specialist company

–

= Not to be carried out by the end-user; the end-user may not carry out installation work!

= To be carried out either by a specialist company or by the end-user.

Loading...

Loading...