SRT45 Off-Highway Truck

8-21

Safety, Operation and Maintenance Manual

8.6.2 Maintenance inspection form for 150hrs

Except daily (10hrs) inspection projects, the following projects also have to nish after running

150hrs.

1. For normally checking

Check leakages, loosened and damaged parts for truck.……….........…………………………

Observe the cracks and welder seam for frame……………................................................…

2. Cummins engine

Check the fasteners for engine………………………………………...........................…………

Check PTO liquid level, rell as required……………………..…………..............………………

3. Transmission

Drain, replace lter and rell (rst time after 150hrs, next time after each 1200hrs).….......…

Remark:

drain, replace lter and rell after 150hrs, if transmission has been xed.

Clean the breather valve for transmission and lubricates again.……...........…......…..………

Check status about block caution lamp for lter.……………………................................…….

4. Main reducer and differential assembly,Planetary assemblyand power take-off (PTO)

Change the gear oil of Main reducer and differential assembly,Planetary assembly and PTO

..…....................................................................................................................................…

Check liquid level, rell as required…………………………………………......…………………

Check and clean the breather valve for rear axle.………………..............………………

Check and clean the breather valve for PTO……………………….............…………...…

Remark: change oil when replace new one or after xed.

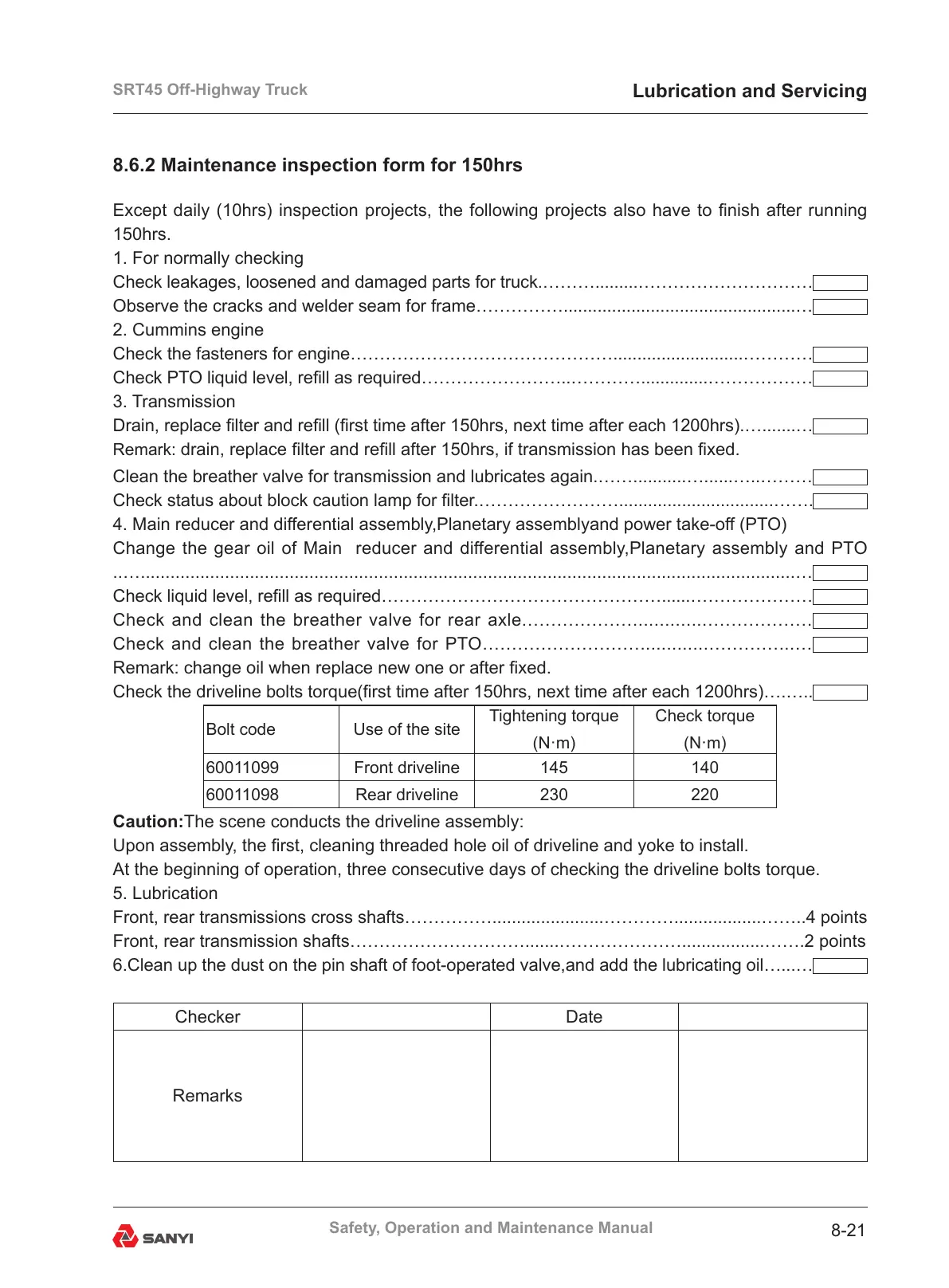

Check the driveline bolts torque(rst time after 150hrs, next time after each 1200hrs)….…..

Bolt code Use of the site

Tightening torque

(N·m)

Check torque

(N·m)

60011099 Front driveline 145 140

60011098 Rear driveline 230 220

Caution:

The scene conducts the driveline assembly:

Upon assembly, the rst, cleaning threaded hole oil of driveline and yoke to install.

At the beginning of operation, three consecutive days of checking the driveline bolts torque.

5. Lubrication

Front, rear transmissions cross shafts…………….......................…………..................……..4 points

Front, rear transmission shafts………………………….......………………….................…….2 points

6.Clean up the dust on the pin shaft of foot-operated valve,and add the lubricating oil…...…

Checker Date

Remarks

Lubrication and Servicing

Loading...

Loading...