SRT45 Off-Highway Truck

8-71

Safety, Operation and Maintenance Manual

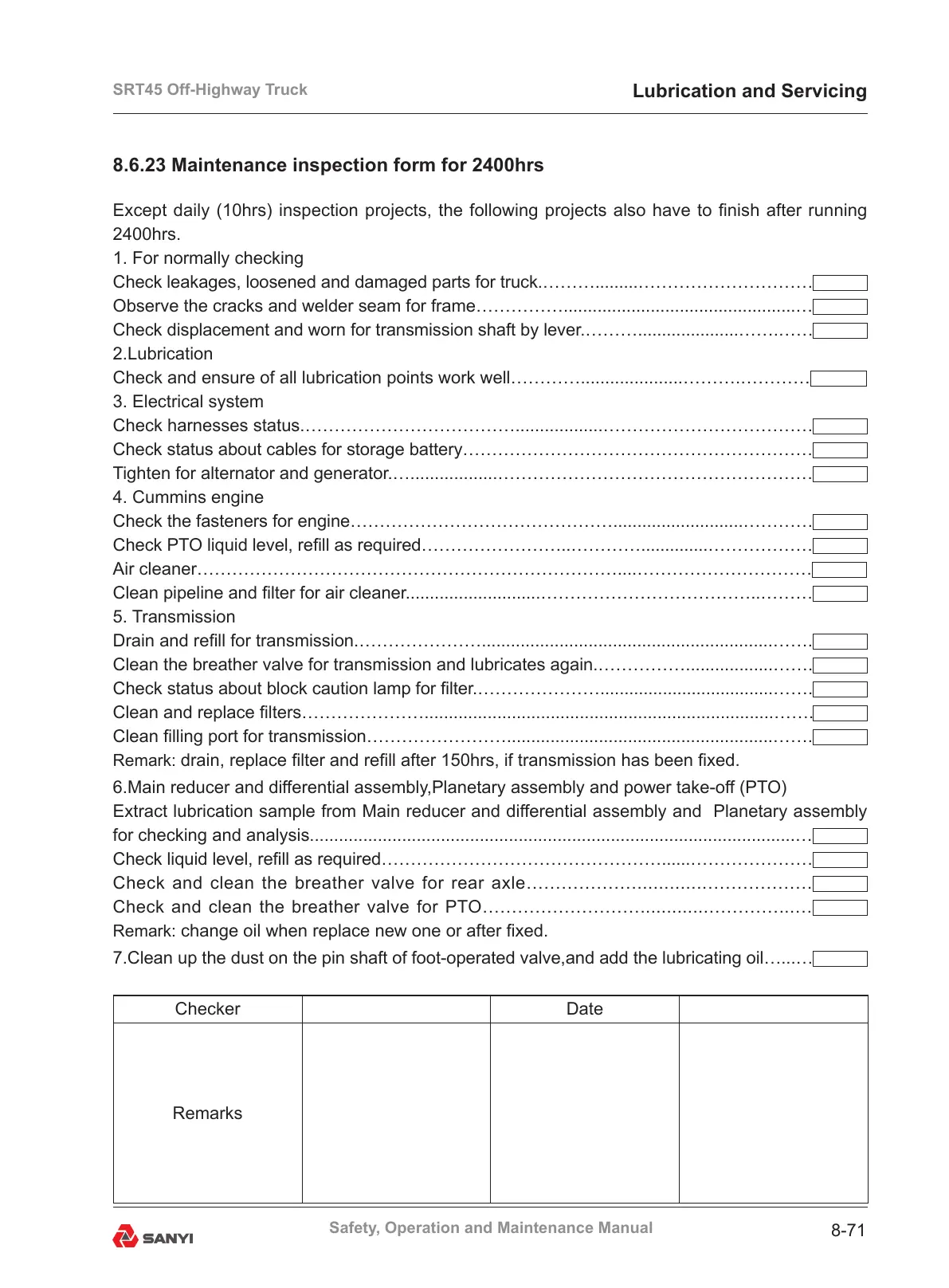

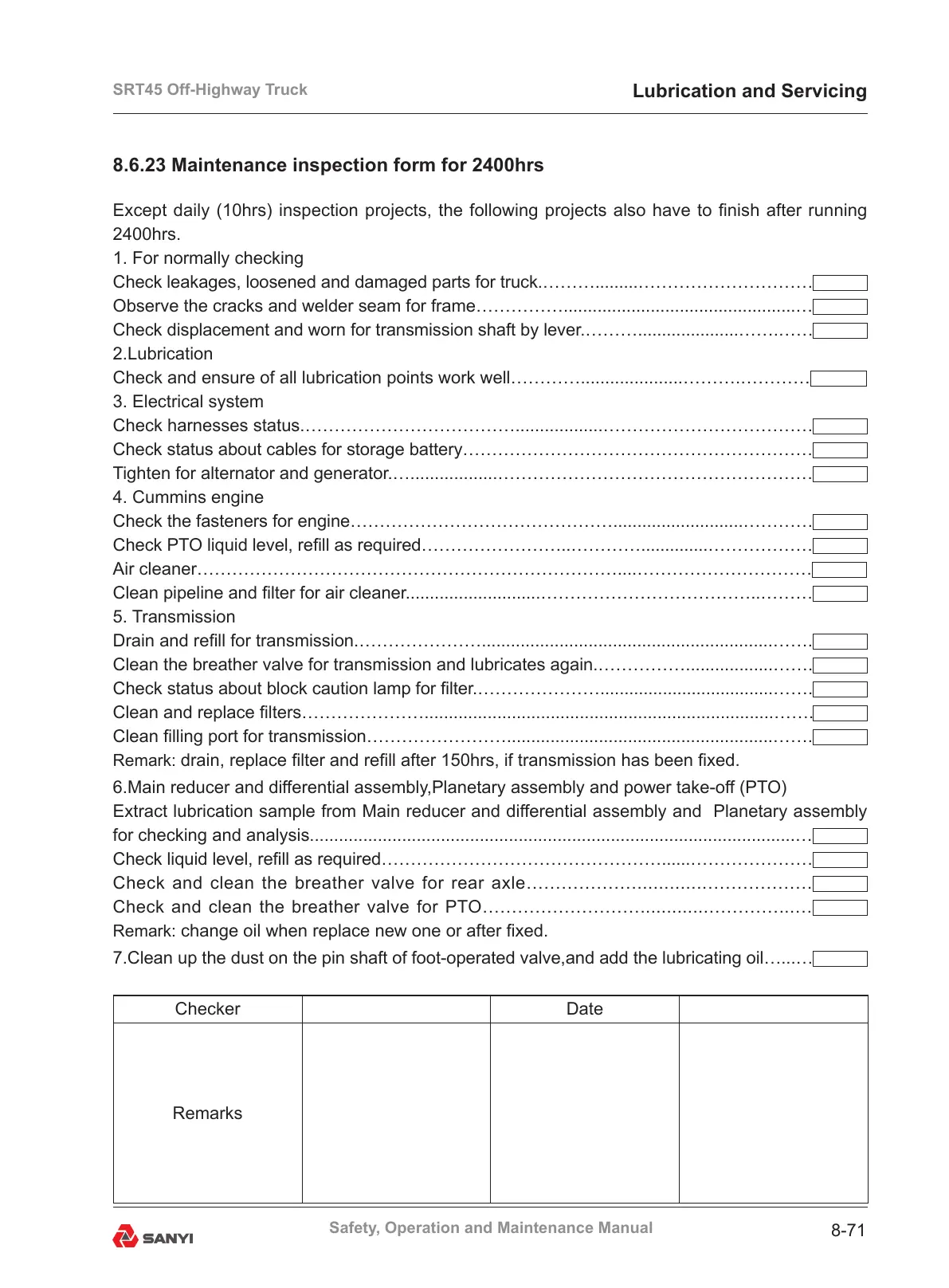

8.6.23 Maintenance inspection form for 2400hrs

Except daily (10hrs) inspection projects, the following projects also have to nish after running

2400hrs.

1. For normally checking

Check leakages, loosened and damaged parts for truck.……….........…………………………

Observe the cracks and welder seam for frame……………................................................…

Check displacement and worn for transmission shaft by lever.……….....................…….……

2.Lubrication

Check and ensure of all lubrication points work well………….....................……….…………

3. Electrical system

Check harnesses status.………………………………..................………………………………

Check status about cables for storage battery……………………………………………………

Tighten for alternator and generator.…..................………………………………………………

4. Cummins engine

Check the fasteners for engine………………………………………...........................…………

Check PTO liquid level, rell as required……………………..…………..............………………

Air cleaner………………………………………………………………....…………………………

Clean pipeline and lter for air cleaner............................………………………………..………

5. Transmission

Drain and rell for transmission.…………………............................................................…….

Clean the breather valve for transmission and lubricates again.……………..................…….

Check status about block caution lamp for lter.…………………....................................…….

Clean and replace lters…………………........................................................................…….

Clean lling port for transmission…………………….......................................................…….

Remark:

drain, replace lter and rell after 150hrs, if transmission has been xed.

6.Main reducer and differential assembly,Planetary assembly and power take-off (PTO)

Extract lubrication sample from Main reducer and differential assembly and Planetary assembly

for checking and analysis....................................................................................................…

Check liquid level, rell as required…………………………………………......…………………

Check and clean the breather valve for rear axle………………..............………………

Check and clean the breather valve for PTO……………………….............…………...…

Remark:

change oil when replace new one or after xed.

7.Clean up the dust on the pin shaft of foot-operated valve,and add the lubricating oil…...…

Checker Date

Remarks

Lubrication and Servicing

Loading...

Loading...