Service Manual for WP6 Diesel Engine

63

Torque vibration damper fastening bolts:

Bolt specification M10-10.9 (×6); Tightening torque: 60~70Nm; Test value: 65~80Nm.

346 Disassembly, Inspection, Maintenance and Assembly of Crankshaft

Bearing Shell

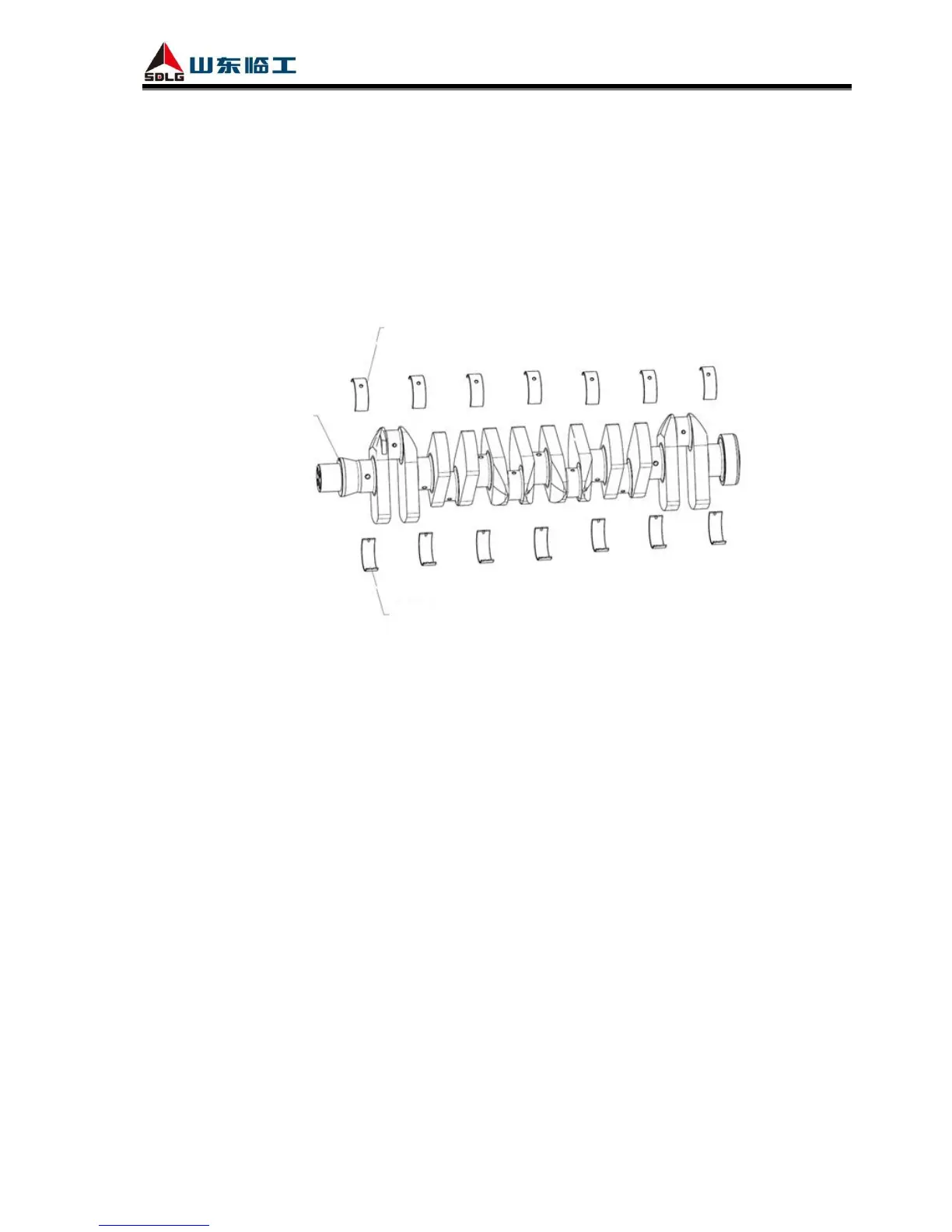

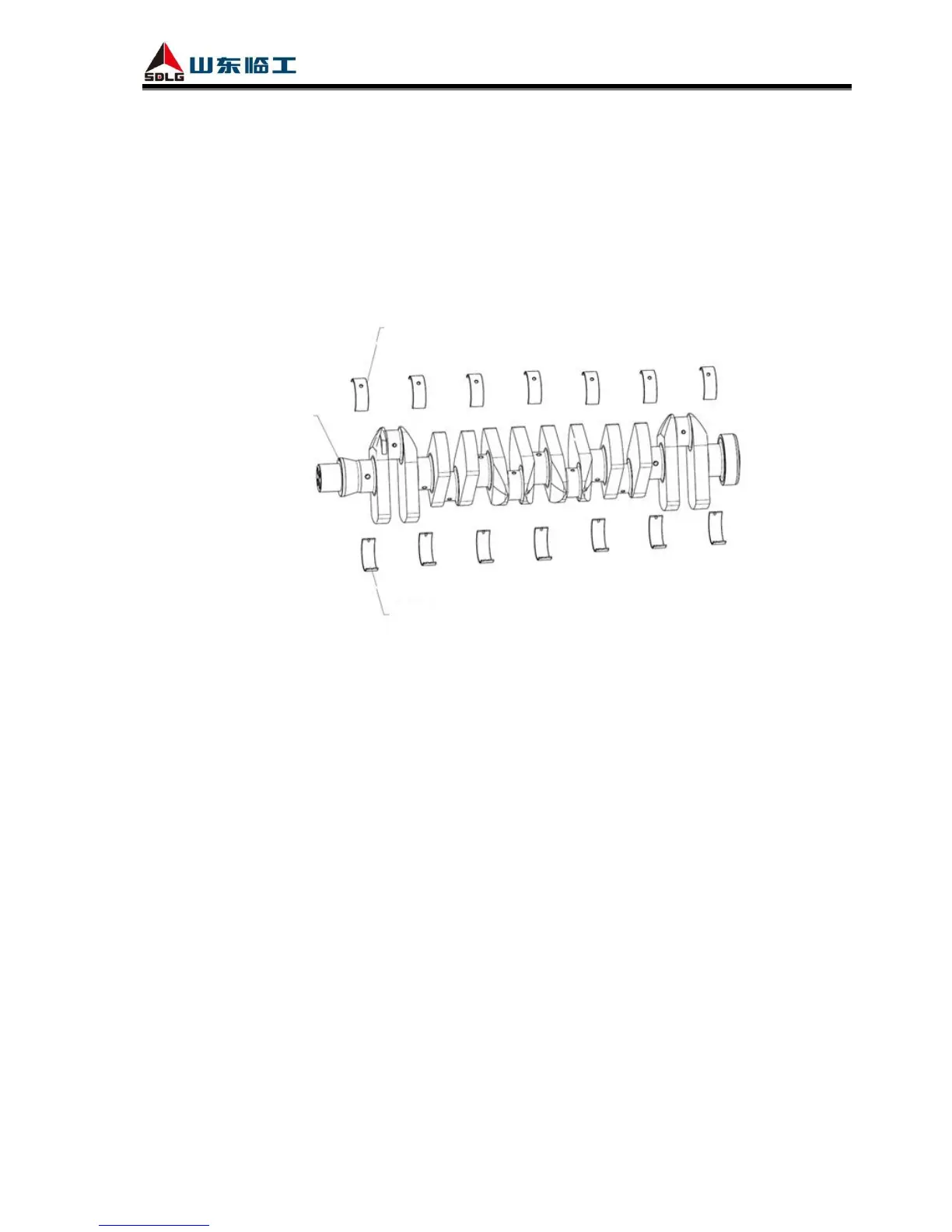

3461 Exploded View of Crankshaft Bearing Shell

Fig. 3-33 Exploded view of crankshaft bearing shell

3462 Steps to Disassemble Crankshaft Bearing Shell

Push the shells out with hand, and mark the removed shells (should be corresponded with holes on

engine block and crankcase).

3463 Inspection and Maintenance of Crankshaft Bearing Shell

(1) Clean the bearing shells and check their wear condition.

(2) Check and ensure there is no peeling, locating lip damage and transverse crack on the shell.

3464 Steps to Assemble Crankshaft Bearing Shell

(1) Clean up main bearing shells and the fitting holes.

(2) If no shell is replaced, then install the two shells into engine block (upper) and crankcase (lower)

respectively (pay attention to the mark, shells should be installed into corresponding holes on

engine block and crankcase), do not mix upper and lower shells, the one with oil groove is

upper one. The shell lips should be aligned and applied with engine oil.

Loading...

Loading...