Service Manual for WP6 Diesel Engine

75

364 Disassembly, Inspection, Maintenance and Assembly of Turbocharger

System

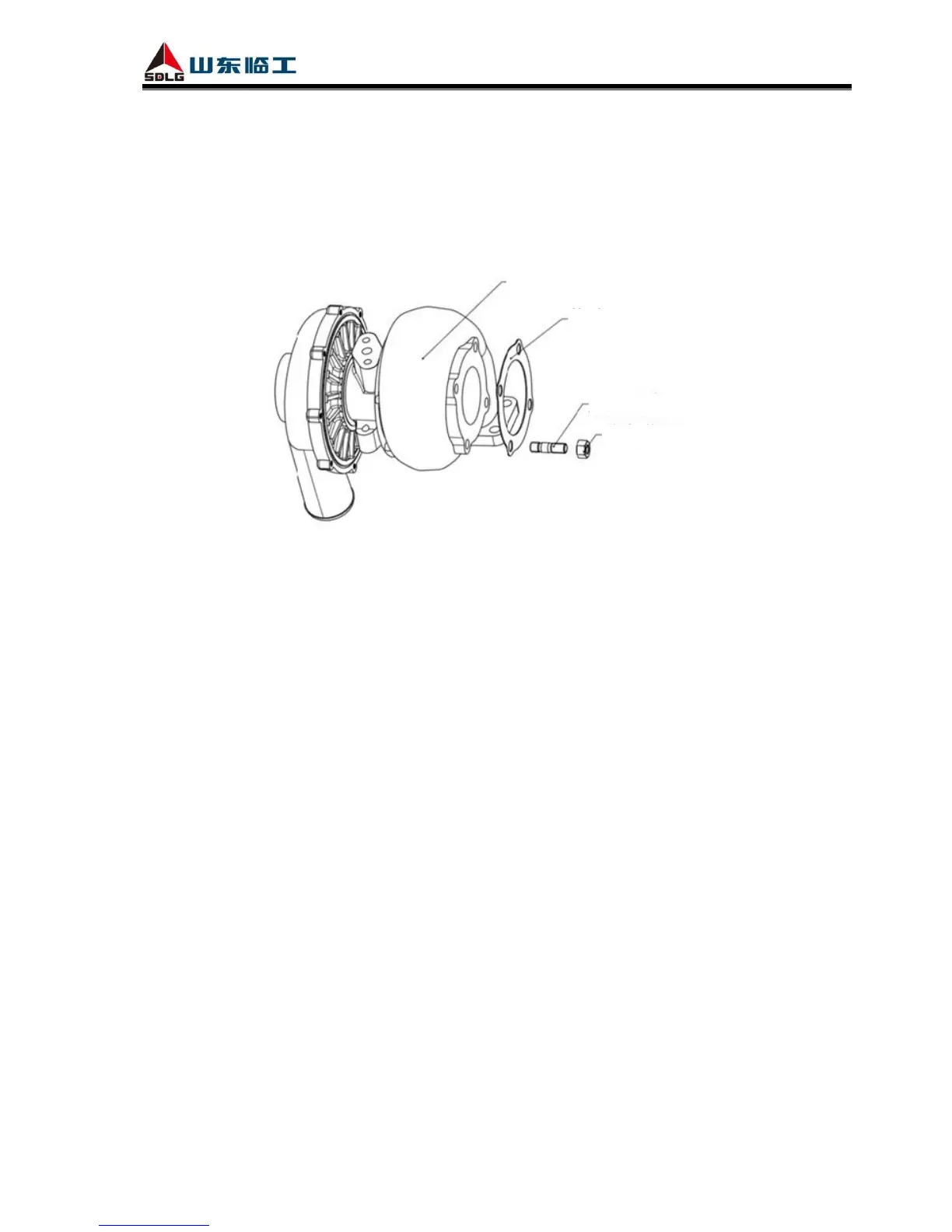

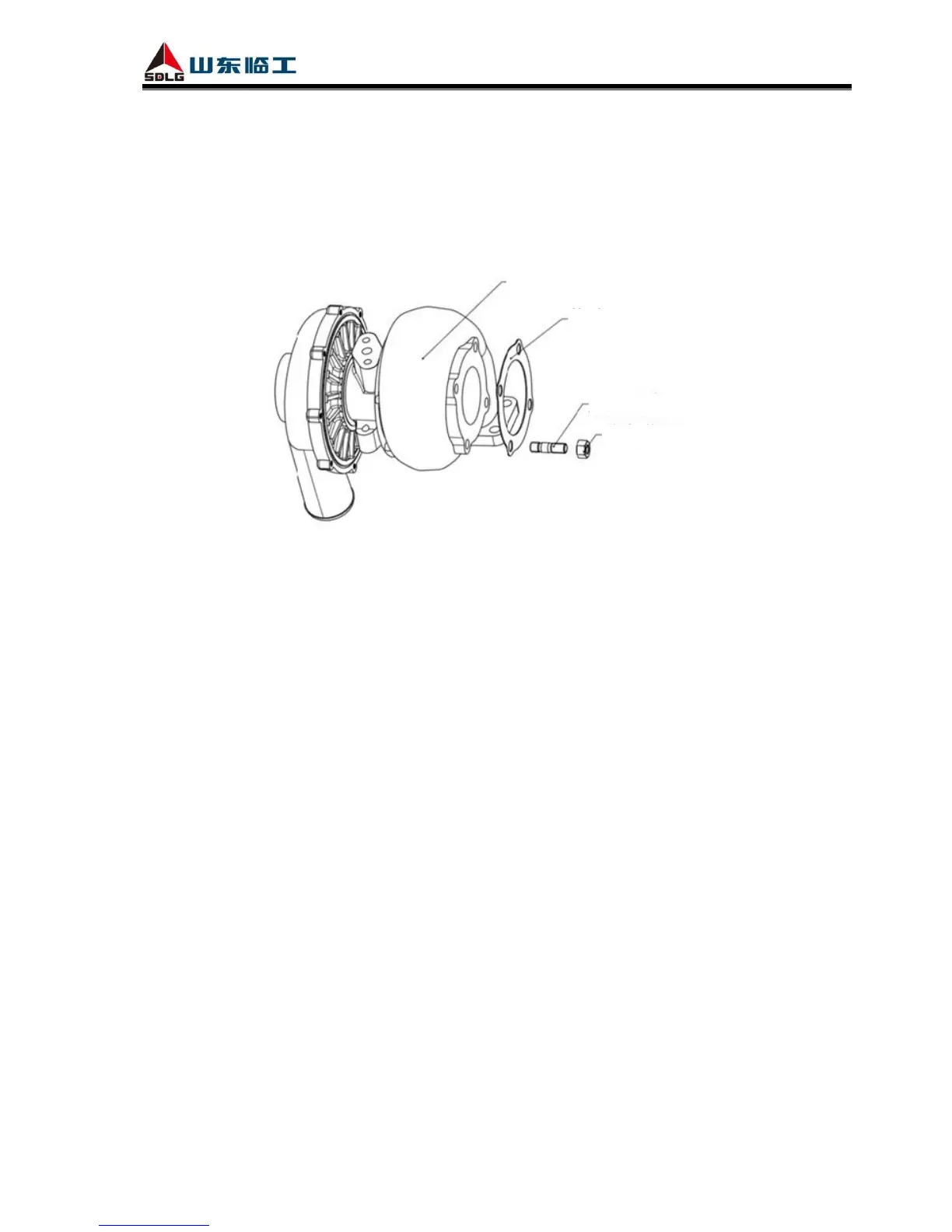

3641 Exploded View of Turbocharger System

Fig. 3-42 Exploded view of turbocharger

3642 Steps to Disassemble Turbocharger System

Disassembling steps are contrary to assembling ones.

3643 Inspection and Maintenance of Turbocharger System

(1) Check service behavior of rotor

Stir compressor impeller gently with your finger, it is normal if the impeller can rotate for more

than one round; if the impeller stopped soon, then it means the bearing is abnormally worn, or there

is clash or jamming problem between rotating parts and fixed parts, you must find out the cause and

eliminate the problem.

(2) Rotor axial movement checking

Press measuring head of dial indicator against compressor end, push and pull the shaft axially and

record value difference of the indicator. As shown in Fig. 3-43. Required range is 0.088~0.118mm,

if exceeds this range, then it indicates that thrust bearing plate or thrust plate and bearing is worn,

you must find out the cause and eliminate the problem.

Loading...

Loading...