15

LEROY-SOMER

2011.01/ h

Installation and maintenance

LSA 46.2 - 4 POLES

ALTERNATORS

3856 en -

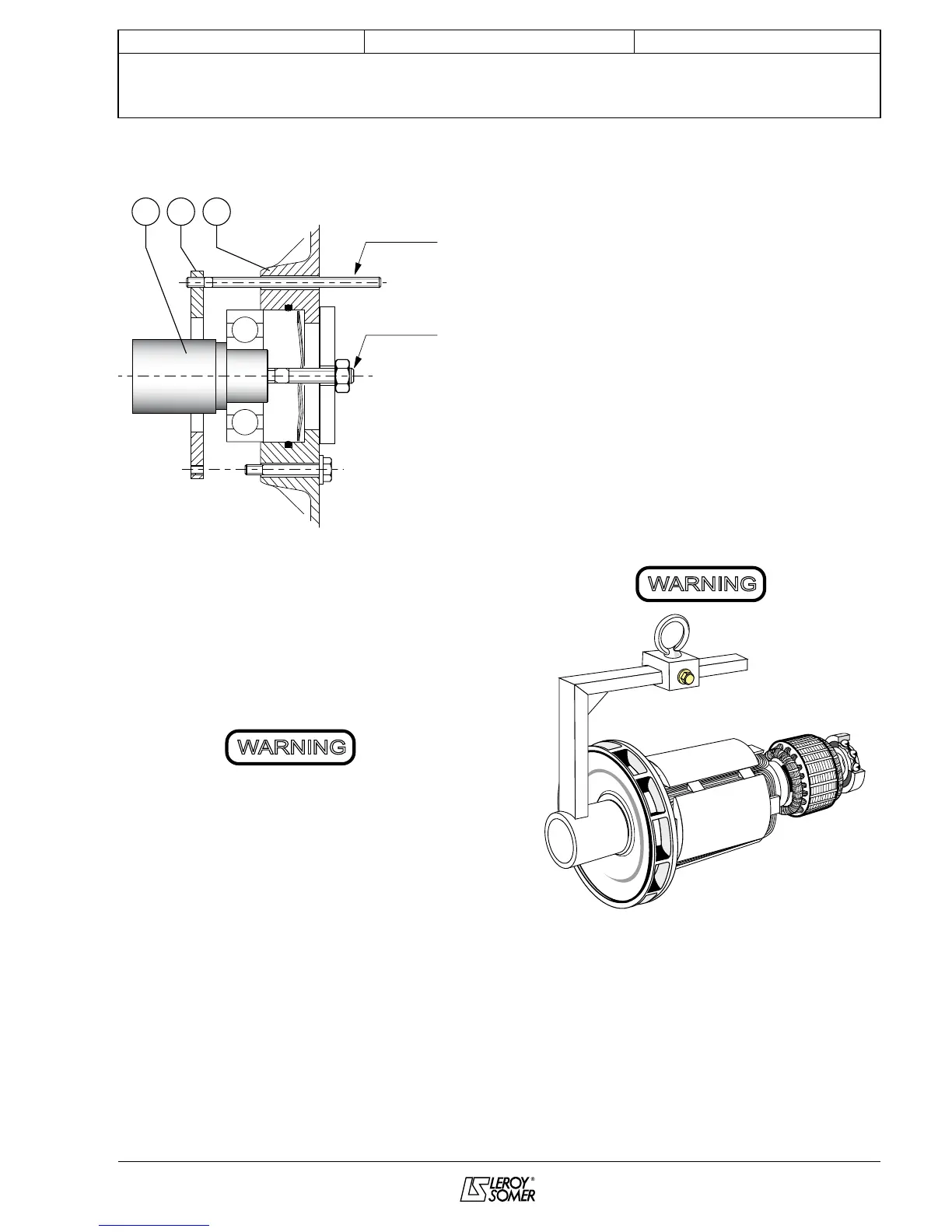

- Slide the threaded rod into the shield hole

to make it easier to assemble (see basic

diagram).

Rotor

NDE shield

Dowel

Nut

Threaded rod

4 78 36

- Fit the thrust bearing screws (78), remove

the threaded rod, t the other screw and

tighten up the assembly.

- Tighten the 4 bearing screws (37).

- Reconnect wires.

- Fit the 2 support screws (122).

- Fit the air inlet louvre (51).

- Replace the cover.

When dismantling the shields, you will

need to change the antifriction bearings,

the “O” ring seal, the preloading (wavy)

washer and adhesive paste.

4.6.6 - Replacing the DE bearing

- Remove the air outlet grille (33).

- Remove the 6 screws (31) from the DE

shield and the 3 screws (62) from the inner

bearing retainer.

- Remove the shield (30).

- Take out the ball bearing (60) using a puller

with a central screw (see section 4.6.5).

- Fit the new bearing, after heating it by

induction to approximately 80 °C.

- Screw a threaded rod into the thrust

bearing (68).

- Ret the shield (30) on the machine.

- Slide the threaded rod into the shield hole

to make it easier to assemble (see basic

diagram).

- Tighten the bottom thrust bearing screws

(78), remove the threaded rod and t the

other screws.

- Tighten the 6 shield screws (31).

- Ret the air outlet grille (33).

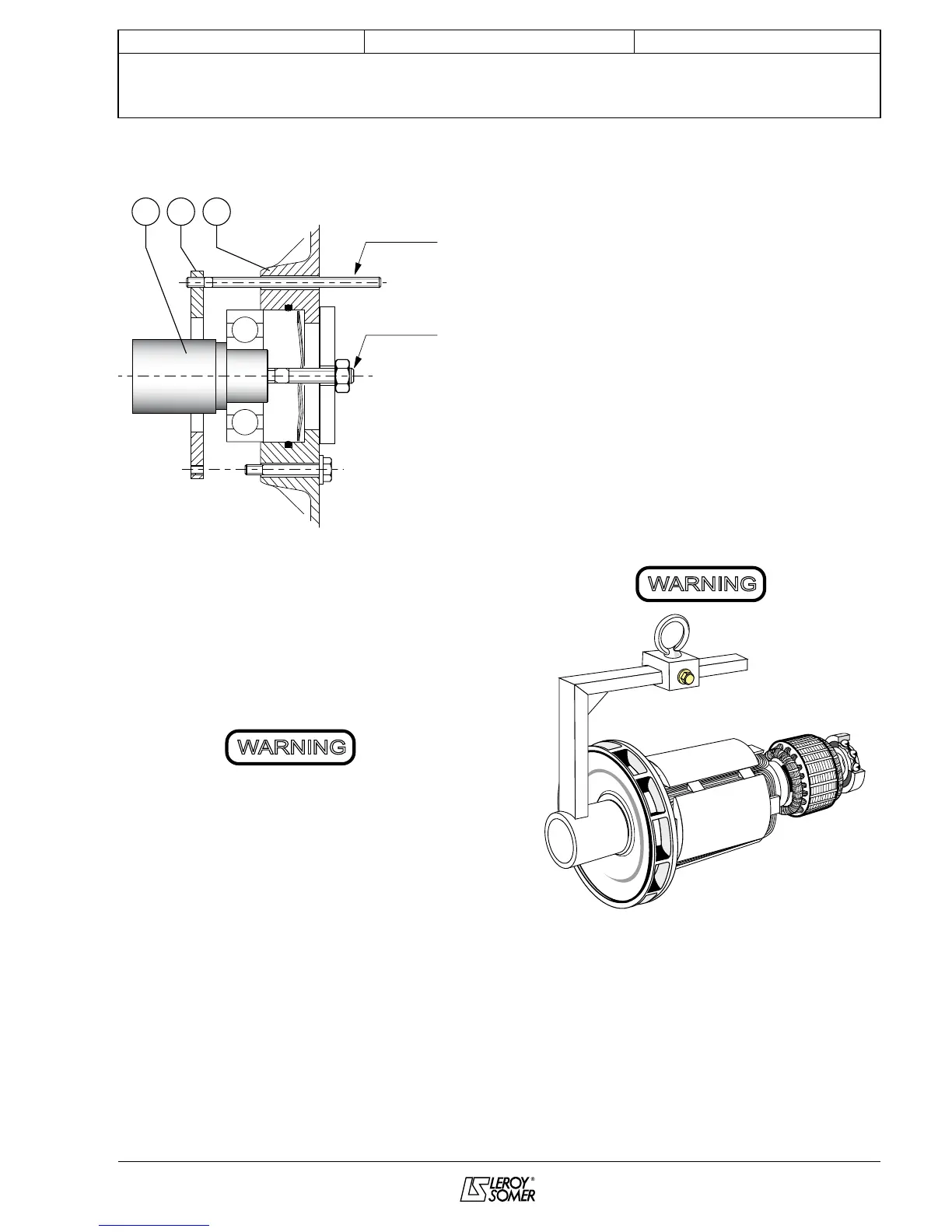

4.6.7 - Dismantling the rotor assembly

- Remove the NDE shield (36) as described

in section 4.6.5.

- Remove the DE shield (30) as described

in section 4.6.6 if it is a double-bearing

machine.

- Support the DE rotor (4) with a strap or with

a support constructed in accordance with

the following drawing.

- Move the strap as the rotor moves in order

to distribute the weight over it.

When dismantling the rotor involves

changing parts or rewinding, the rotor

must be rebalanced.

4.6.8 - Reassembling the machine

- Mount the rotor (4) in the stator (1) (see

drawing above) taking care not to knock the

windings.

Loading...

Loading...