8-4

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES

Fuel system (in-line type fuel injection pump) - Bleed air

Bleed air at fuel filters and then at the fuel injection

pump. Bleeding from upstream to downstream is

effective for this job.

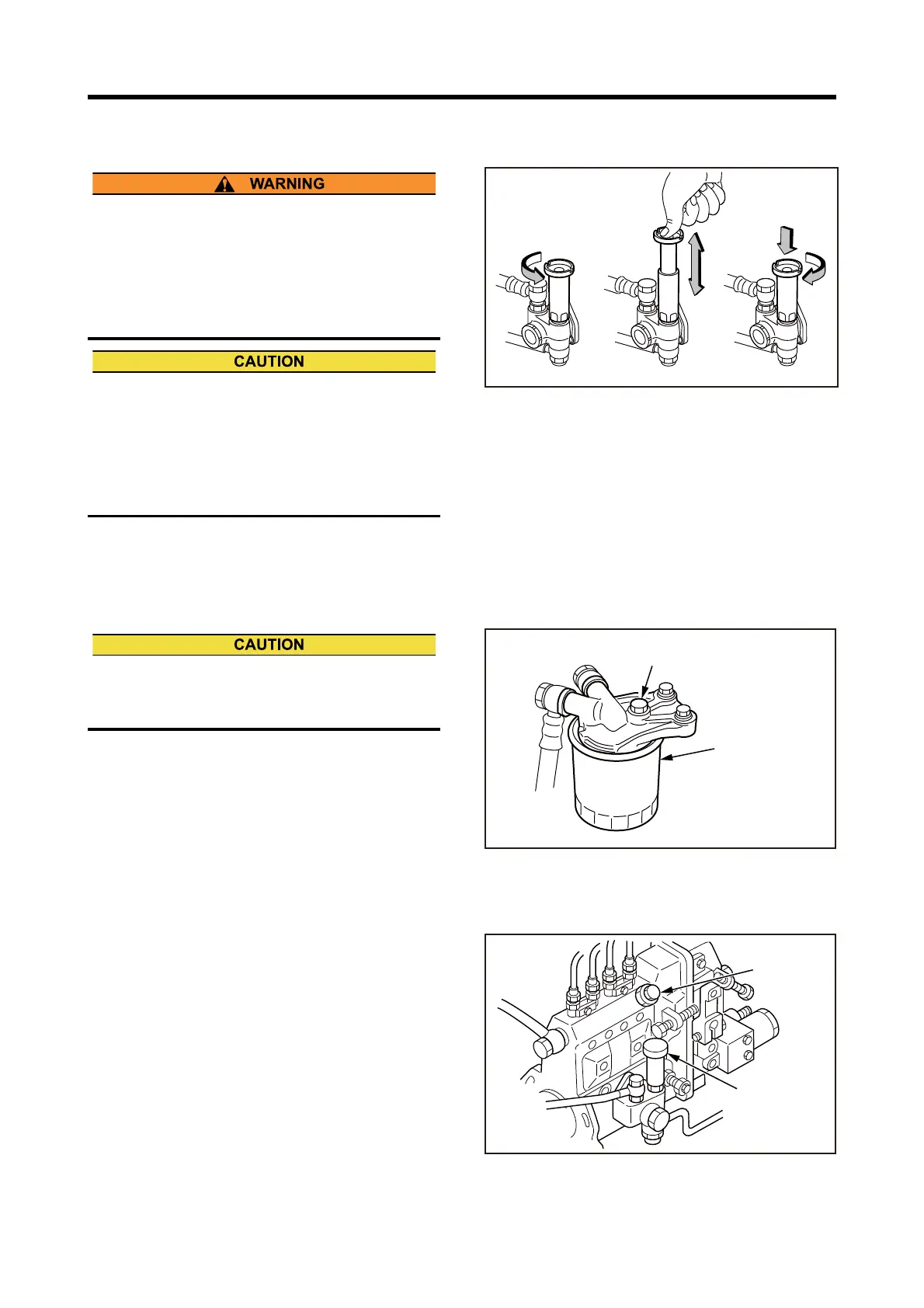

Fig. 8-5 Priming pump - Handle

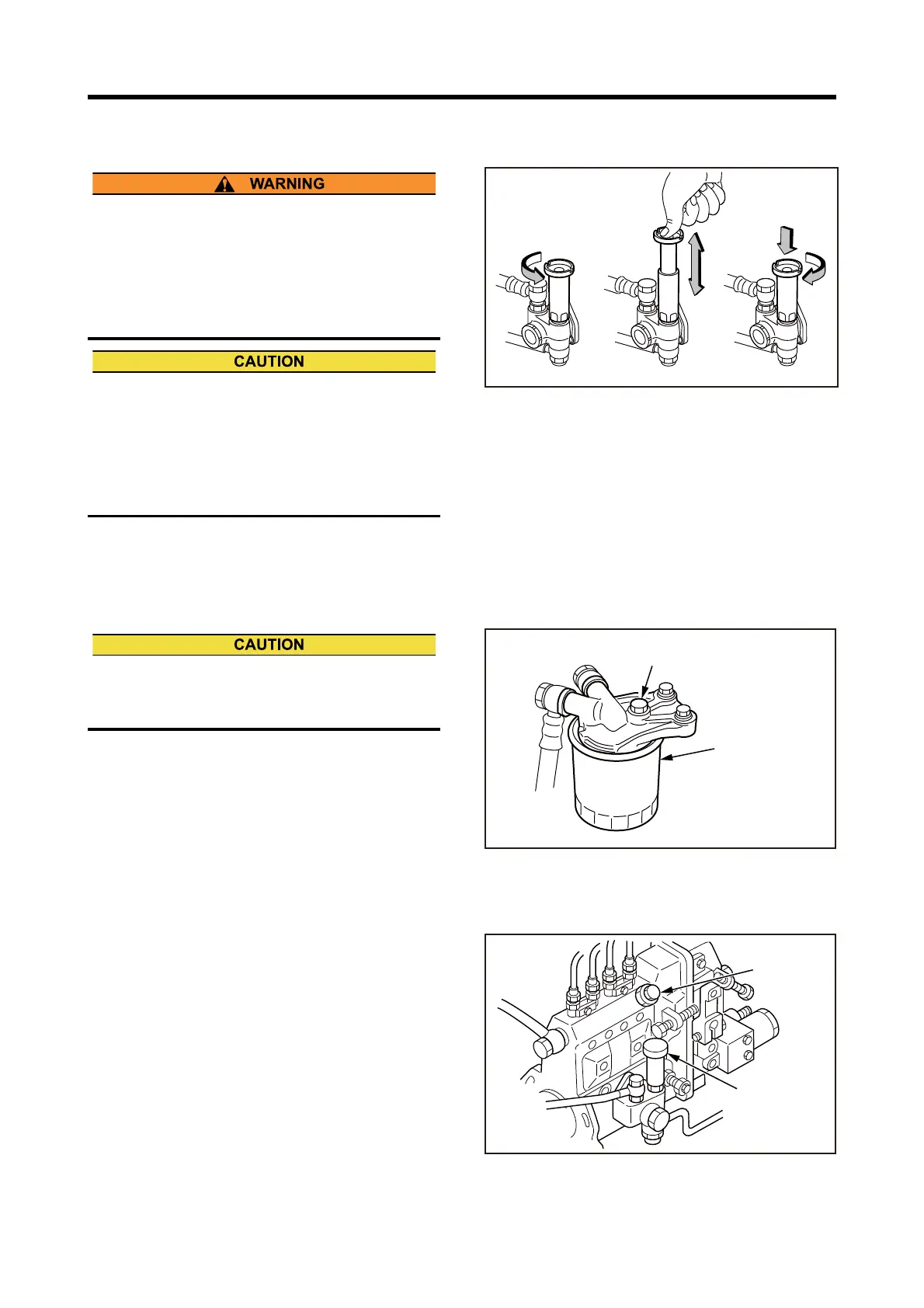

Fuel filter - Bleed air

1. Loosen the air vent plug on the fuel filter about 1.5

turns.

2. Turn the priming pump counterclockwise to unlock,

and prime the fuel filter.

3. When the fuel from the air vent plug becomes free

from air bubbles, stop priming and tighten the air

vent plug to the specified torque.

Fig. 8-6 Fuel filter - Bleed air

Fuel injection pump - Bleed air

1. Loosen the air vent plug on the fuel injection pump

by rotating about 1.5 turns.

2. Move the priming pump up and down. When the

fuel flow from the air vent plug becomes free of

bubbles, push and turn the priming pump clockwise

to lock.

3. Tighten the air vent plug on the fuel injection pump.

Fig. 8-7 Fuel injection pump - Bleed air

When fuel overflow from the air vent plug, wipe thor-

oughly with a cloth. Spilled fuel causes fire hazard

After bleeding, lock the priming pump securely.If the

cap is not locked tightly, the priming pump can be

damaged, causing a fuel leakage that could lead to a

fire.

Tighten the priming pump before closing the air vent

plug.

Do not close all air vent plugs and cocks before lock-

ing the priming pump, as the priming pump will not

return to the original position due to internal pres-

sure.

[Lock release] [Priming] [Lock]

Turn counter-

clockwise

Move cap up

and down

While depressing,

turn coockwise

If air vent plugs, the thread portion of the bracket, or

sealing washers are damaged, replace them with

new ones.

Air vent

plug

Priming pump

Loading...

Loading...