ENGLISH

16 610.40 064.01 Siemens AG

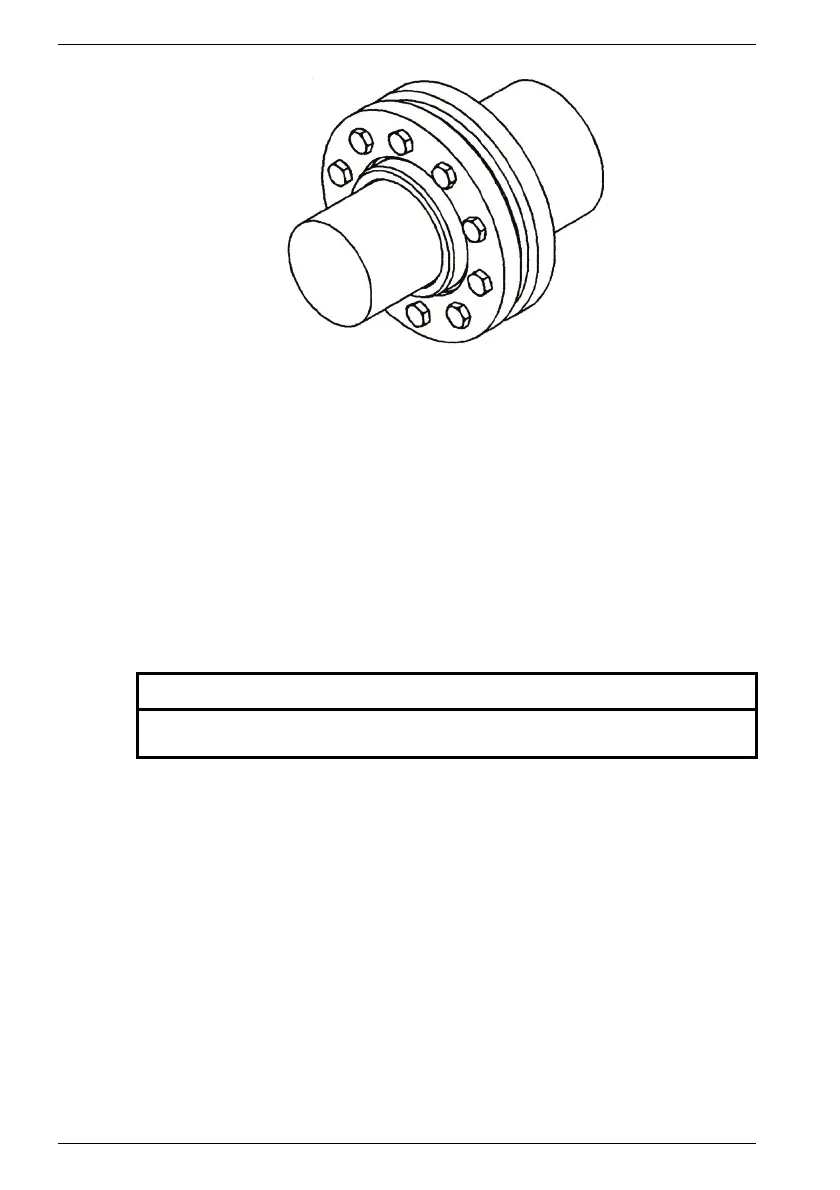

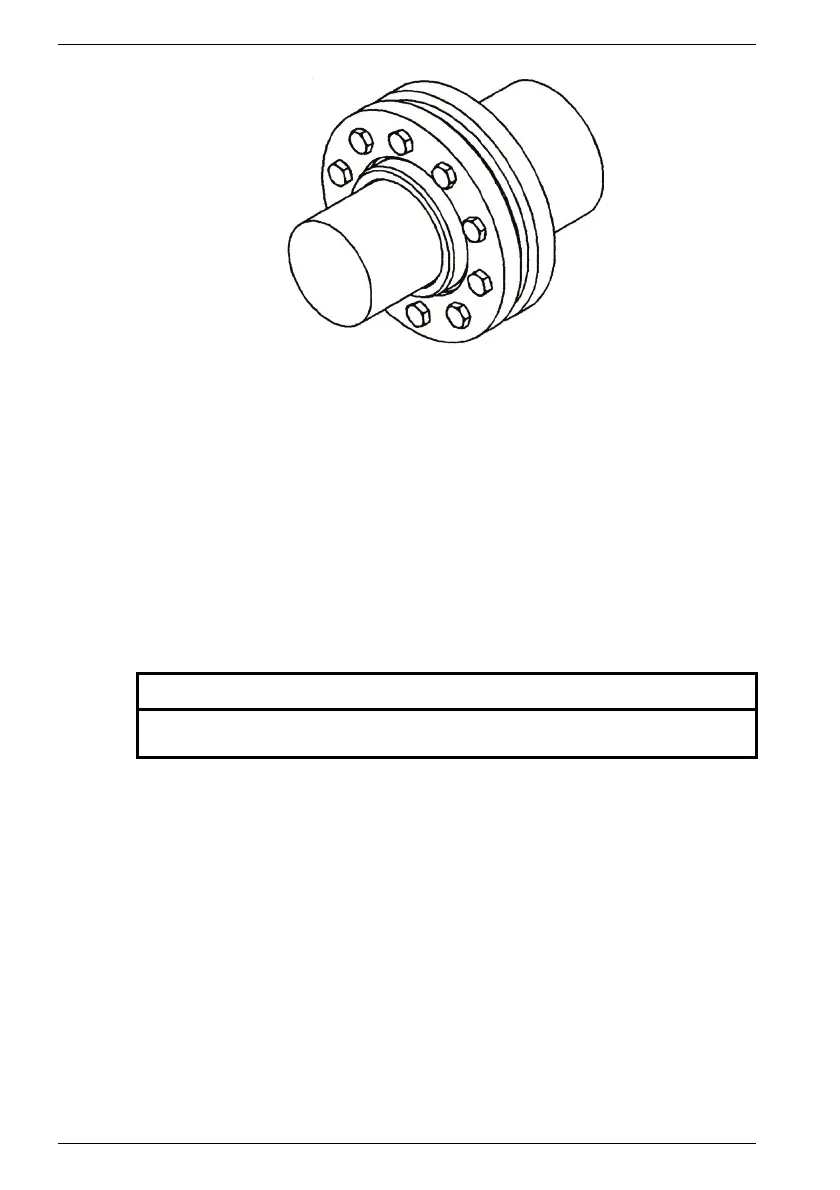

Fig. 6 Hollow shaft (example)

Shrink disc connection:

The hollow shaft is connected to the smooth machine drive shaft by frictional engage-

ment produced by elastically constricting the hollow shaft with a shrink disk. This shaft-

hub link has absolute zero-backlash, and is therefore also non-wearing.

It can transmit high torques and axial forces with a high degree of true-running accuracy

(as a result of its self-centering characteristic).

The hollow shaft is made of high-tensile tempering steel.

Hollow shaft models (dependent upon size of gearbox):

- Hollow shafts with slots in the shrink seating area:

Machine shaft with tolerance complying with ISO h9.

- Hollow shafts without slots in the shrink seating area:

Machine shaft with tolerance complying with ISO h6.

CAUTION

The end of the hollow shaft with the shrink disk seating must not be loaded with

a radial operational force.

Loading...

Loading...