Application and Operation

6.5 Command Generator

Product User Manual

Operating Instructions, Version AE 12/2009, A5E01454341C

119

6.5 Command Generator

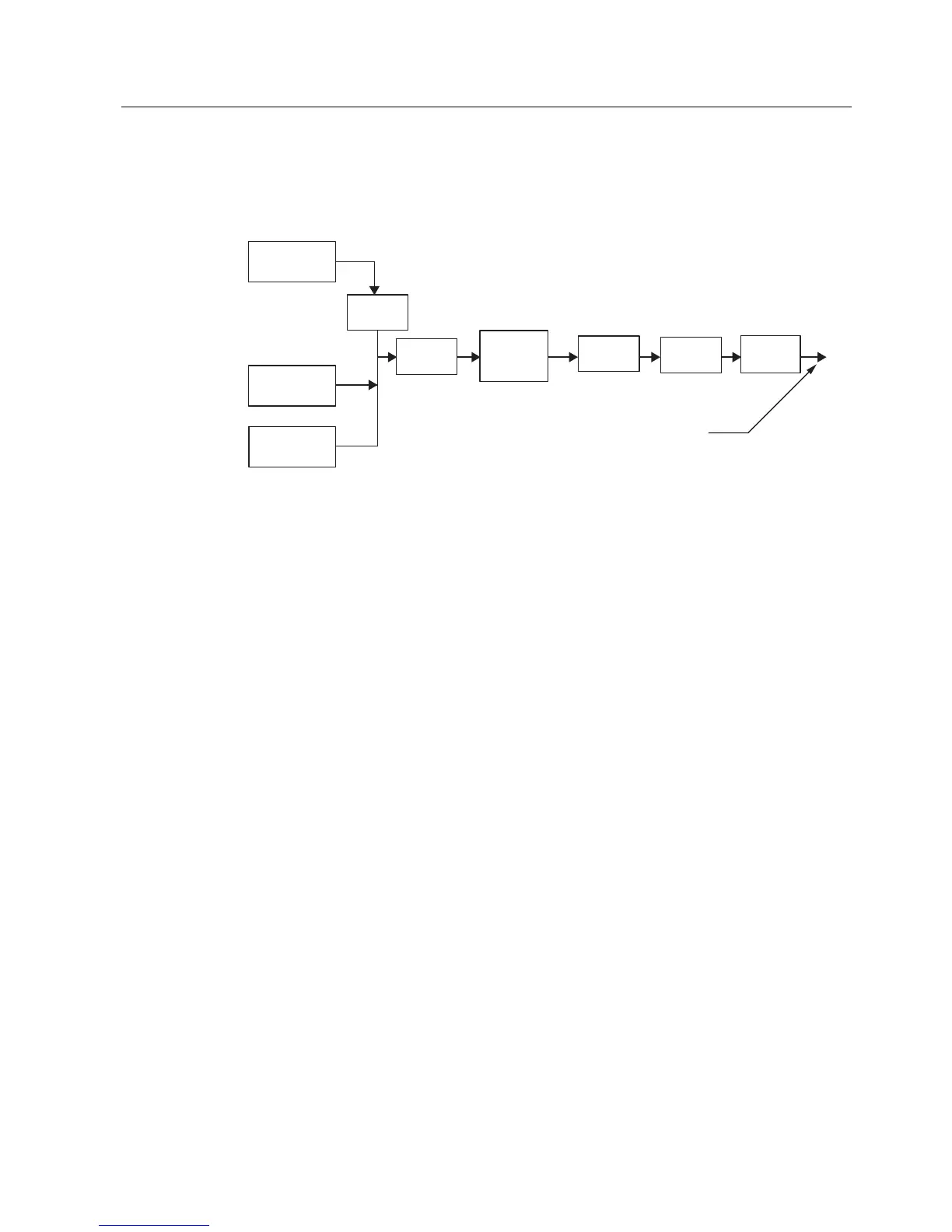

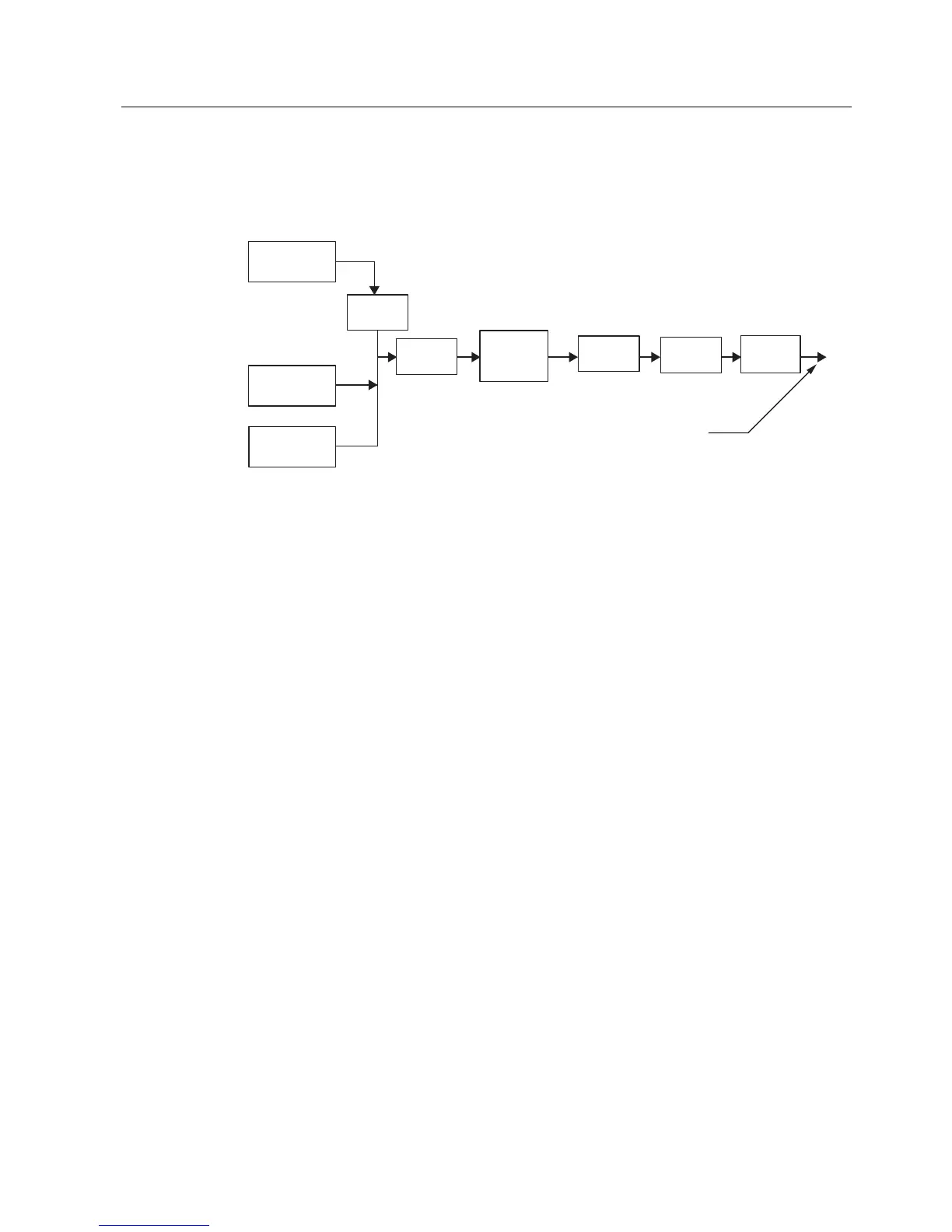

This section defines the Command generator functional blocks shown in Figure " Command

Generator"

$QDORJ,QSXW

6RXUFHV

5DWLR

&RQWURO

3,'&RQWUROOHU

6HWSRLQW6RXUFHV

6SHHG

3URILOH

&ULWLFDO6SHHG

$YRLGDQFH

3RODULW\

&RQWURO

6SHHG

5DPS

6SHHG

/LPLWV

5HIHUHQFH

Figure 6-5 Command Generator

6.5.1 Raw Speed Reference

The NXG Control includes provisions for output speed demand entry as required for a

specific application. The active reference source is configured per specific system

requirements and can be dynamically changed. This is implemented via the drive’s "System

Program" as defined in Section "System Program (SOP)". An overview of each of the major

functional blocks is defined next, and a detailed description is provided in the

NXG Control

Manual, 19001588

.

Analog Input Sources

The NXG control provides a means to provide multiple analog input sources that can be

selected as demand inputs to the system. The control scales these analog values into

internal units, and monitors the levels for possible loss of signal conditions. The control

includes provisions for predetermination of VFD action upon loss of signal conditions,

including maintain speed, transition to preset speed, or trip VFD.

Ratio Control

The Ratio control is simply a fractional scaling unit available for the analog reference signals.

This feature allows multiple drives to share the same reference signal with rescaled output

signal levels.

PID Controller

The PID loop is programmable from User Interface. The PID Command set point can be

either an external Analog Input or an internal set point. The PID Feedback is always from an

Analog Input. The Proportional, Integral, and Derivative gains, as well PID output limits, are

programmable.

Loading...

Loading...