Installing the Power Module

33 |

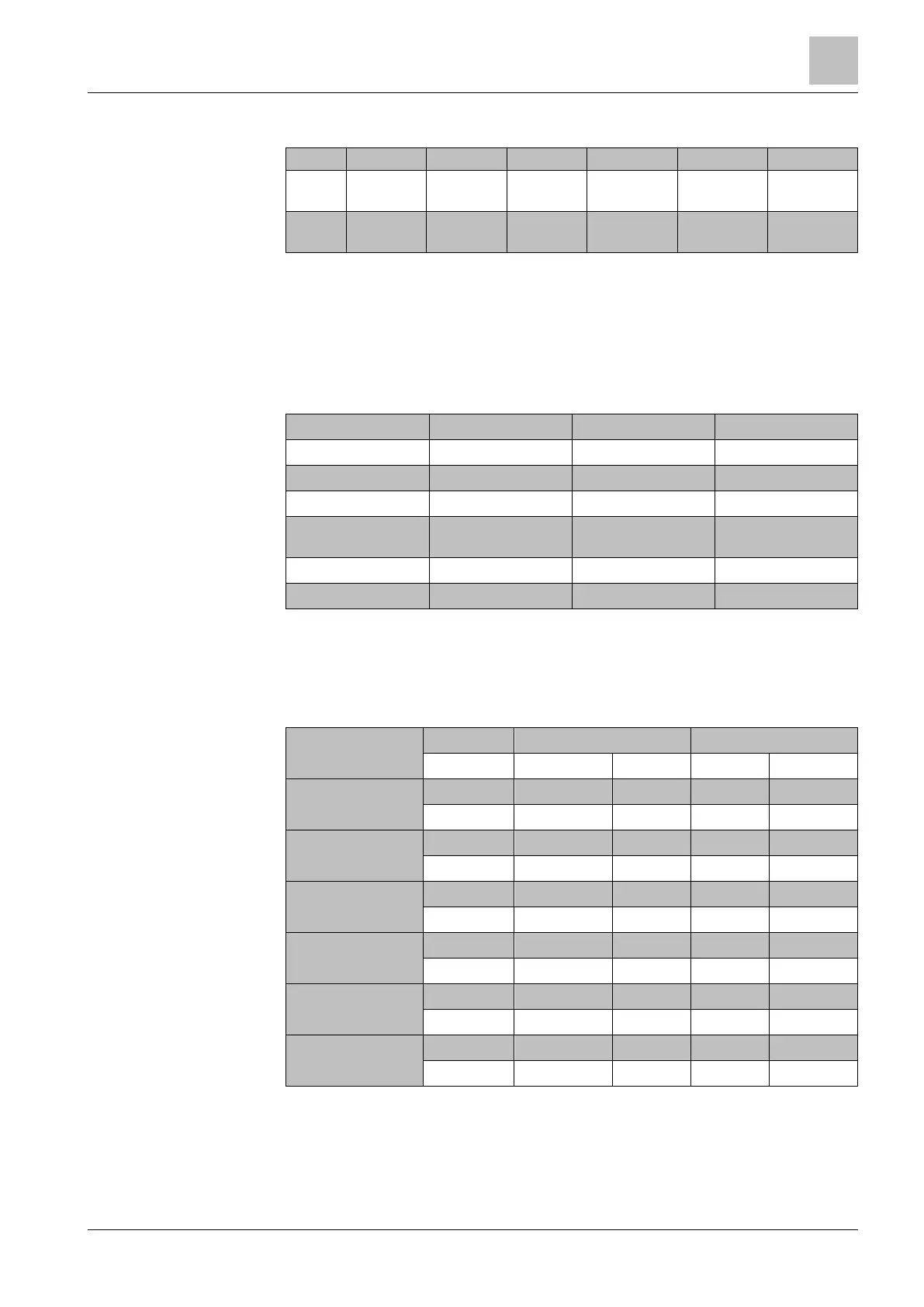

Overview of tightening torques

IP20 0.4 Nm...

0.5 Nm

0.55 Nm...

0.6 Nm

1.2 Nm...

1.5 Nm

6 Nm 6 Nm 13 Nm

IP55 0,5 Nm

(4,4 lbf.in)

0,6 Nm

(5,3 lbf.in)

1,5 Nm

(13,3 lbf.in)

M6: 6 Nm

(53,0 lbf.in)

M6: 6 Nm

(5,3 lbf.in)

M8: 13 Nm

(115 lbf.in)

Table 7: Overview of tightening torques

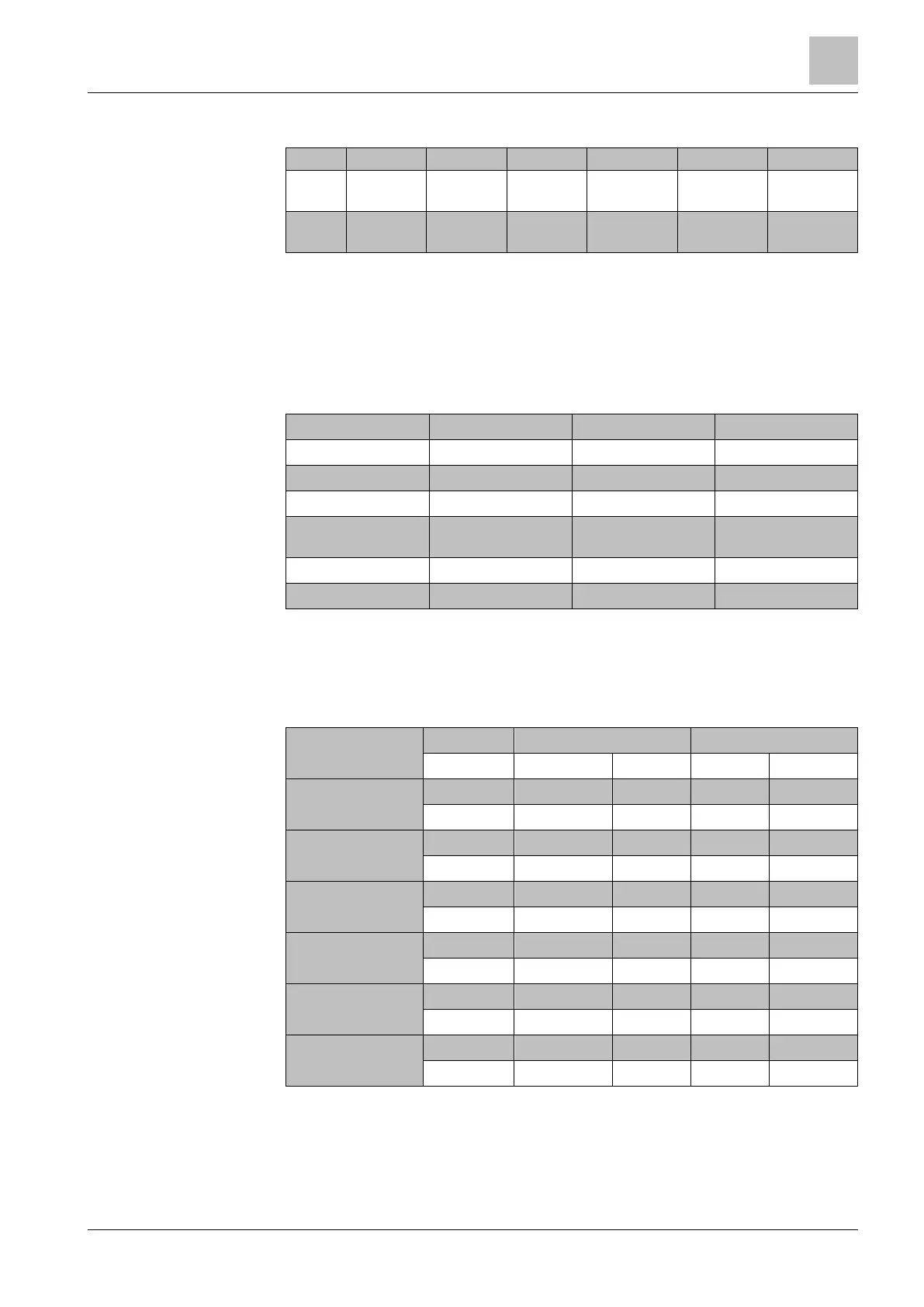

5.3.2.2 Overview of motor cable lengths and cross sections

The following tables contain all relevant information about required cable lengths

and cross sections. Adherence to the specified values is essential in order to

ensure that the installation complies with EMC regulations.

Shielded C2 25 m (80 ft)

Shielded C3 50 m (164 ft)

Unshielded No 100 m (330 ft)

Shielded C1

(conducted only)

25 m (80 ft) with IP54

50 m (164 ft) with IP20

Shielded C2 50 m (164 ft)

Unshielded No 100 m (330 ft)

● You may only use copper wire of class 1, 75 °C (for compliance with the UL in

frame sizes A to C).

● Ensure that the appropriate circuit breakers or fuses with the specified current

rating are connected between the power supply and the drive.

2

0.37...1.5 1.0 … 2.5 18…14 0.5 4.4

2.2...3 1.5…2.5 16…14 0.5 4.4

4 2.5…6.0 14…10 0.6 5.3

5.5...7.5 4.0…6.0 12…10 0.6 5.3

11 6.0 … 16 10 … 5 1.5 13.3

15...18.5 10 … 16 7 … 5 1.5 13.3

22.0...30 10...35 5...2 6 53

37 25...50 3...2 6 53

45 35...50 2...4/0 6 53

55 70...120 2/0...4/0 13 115

75...90 95...120 3/0...4/0 13 115

0.37...1.5 1.0 … 2.5 18…14 0.5 4.4

Cross sections of power

cables

Loading...

Loading...