| 98

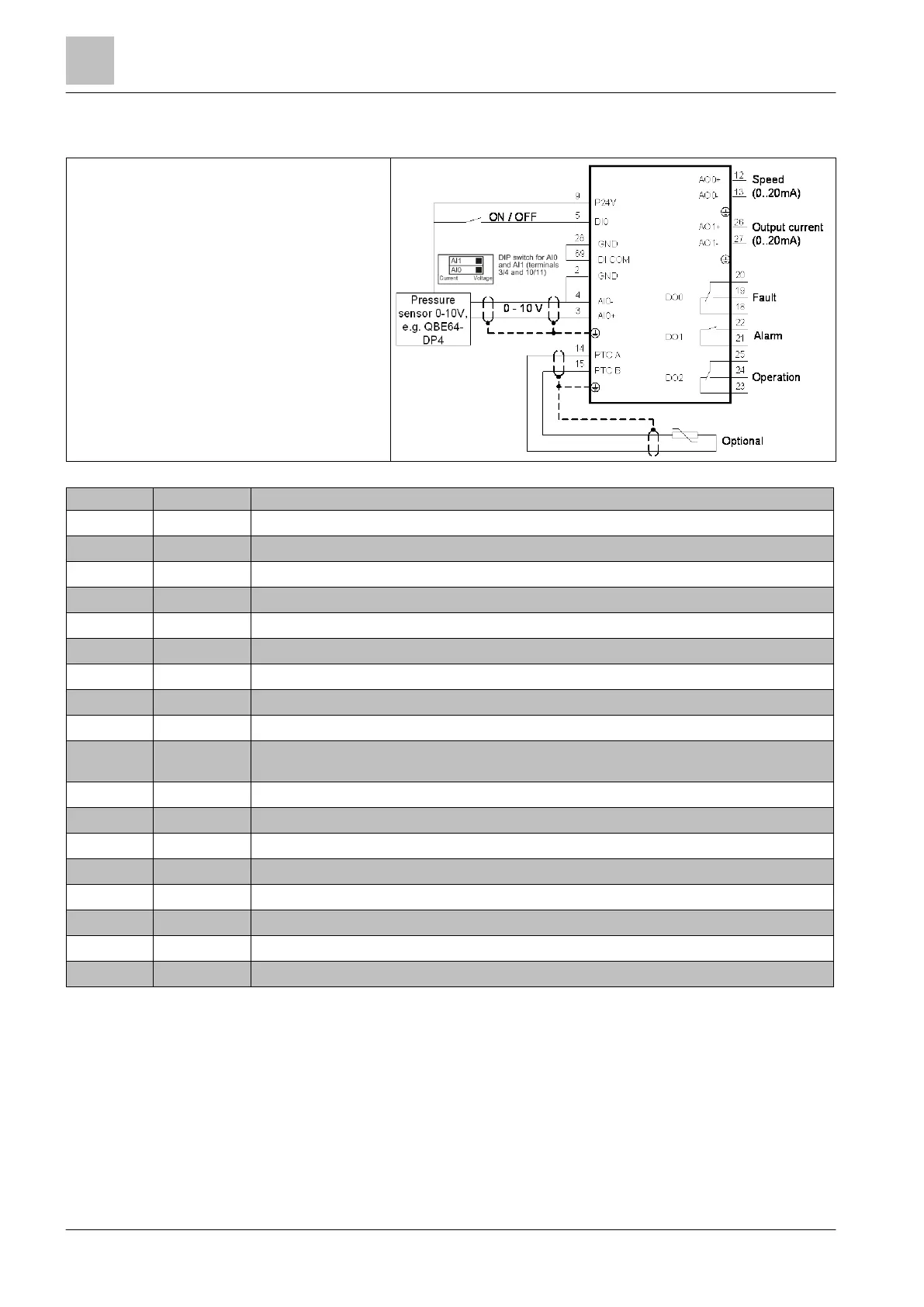

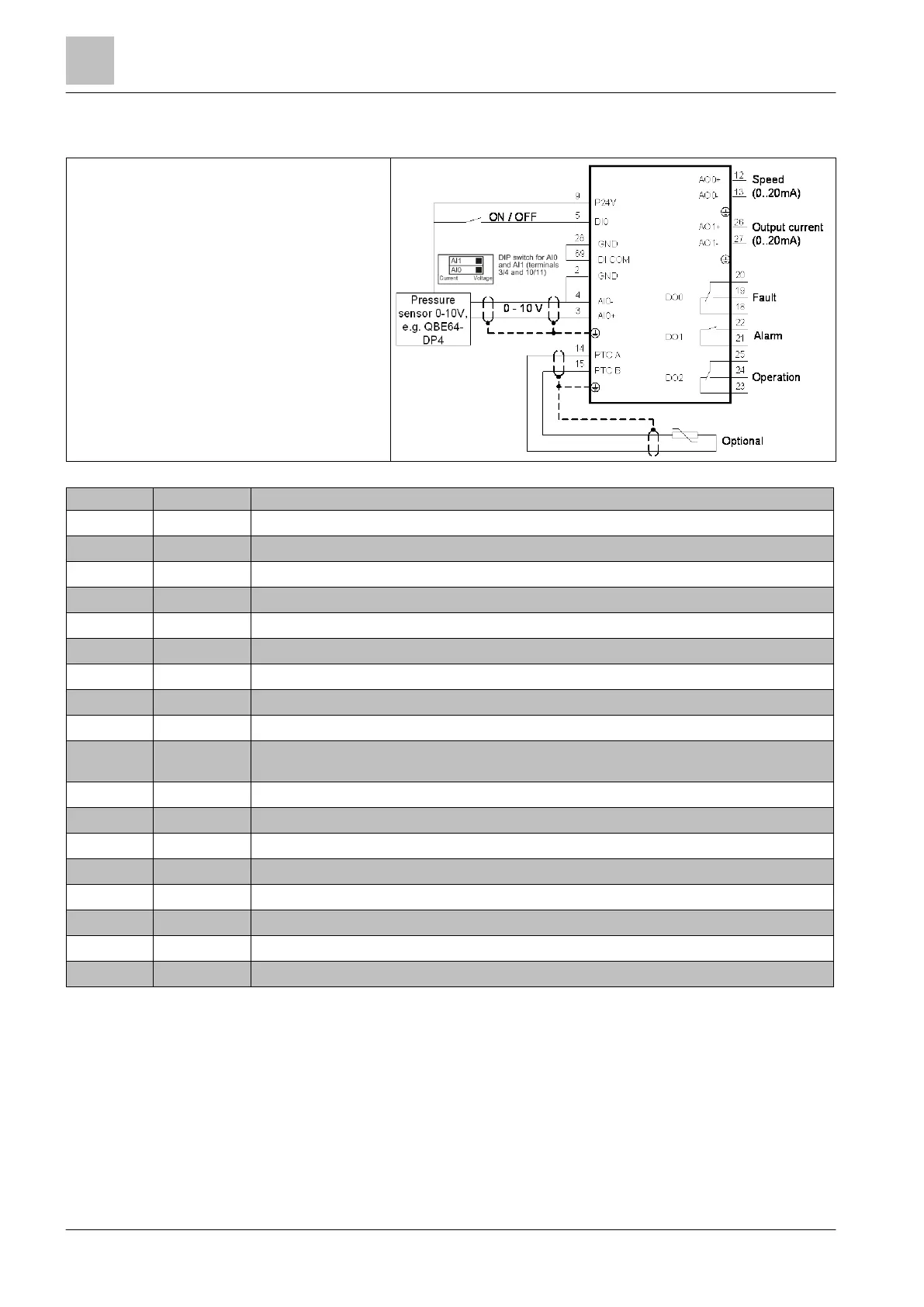

7.2 Pump pressure control

● Macro 103 "Pump pressure control"

● Differential pressure regulated by integrated PID

controller

● Flying restart and automatic restart activated

● Error message: Digital output 0

● Status display: Digital output 2

When selecting this application using macro 103, the

technological unit remains unchanged at [%]. If

necessary, adapt the unit as described in the parameter

list. Select the values depending on the used sensor.

p596 4 Reference variable of the technological unit

p0010 5 Parameter filter change, technological unit

p595 3 Selection of technological unit: bar

p0010 0 Parameter filter ready

p756[0] 0 Unipolar voltage input (0...10 V)

p0840 r722.0 ON / OFF (OFF1)

p1200[0] 1 Flying restart always active (start in setpoint direction)

p1210 26 Acknowledging all faults and restarting for an ON command

p2200[0] 1 Technology controller enable

p2201[0] 2 bar Technology controller fixed value 1

Set the pressure setpoint to suit the application. This example uses a 0 to 4 bar sensor (e.g. QBE64).

p2253[0] p2201 Technology controller setpoint 1

p2257 30s Technology controller setpoint ramp-up time

p2258 30s Technology controller setpoint ramp-down time

p2264[0] r755[0] Technology controller actual value

p2265 10 s Technology controller actual value filter time constant

p2267 4.2 bar Technology controller upper limit actual value

p2268 -1 bar Technology controller lower limit actual value

p2293 30 s Technology controller ramp-up/ramp-down time

Loading...

Loading...