Service, maintenance and fault rectification

| 98

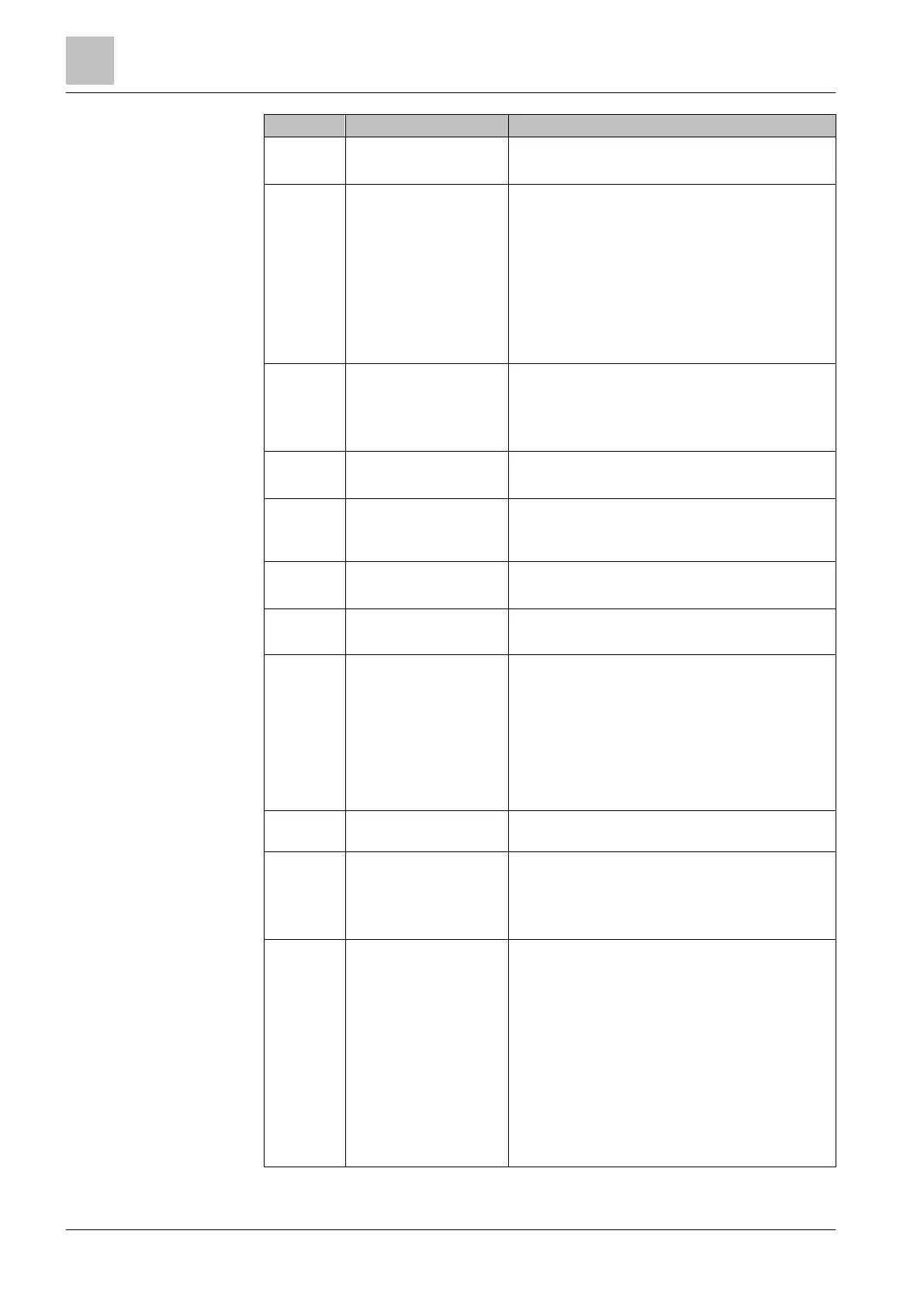

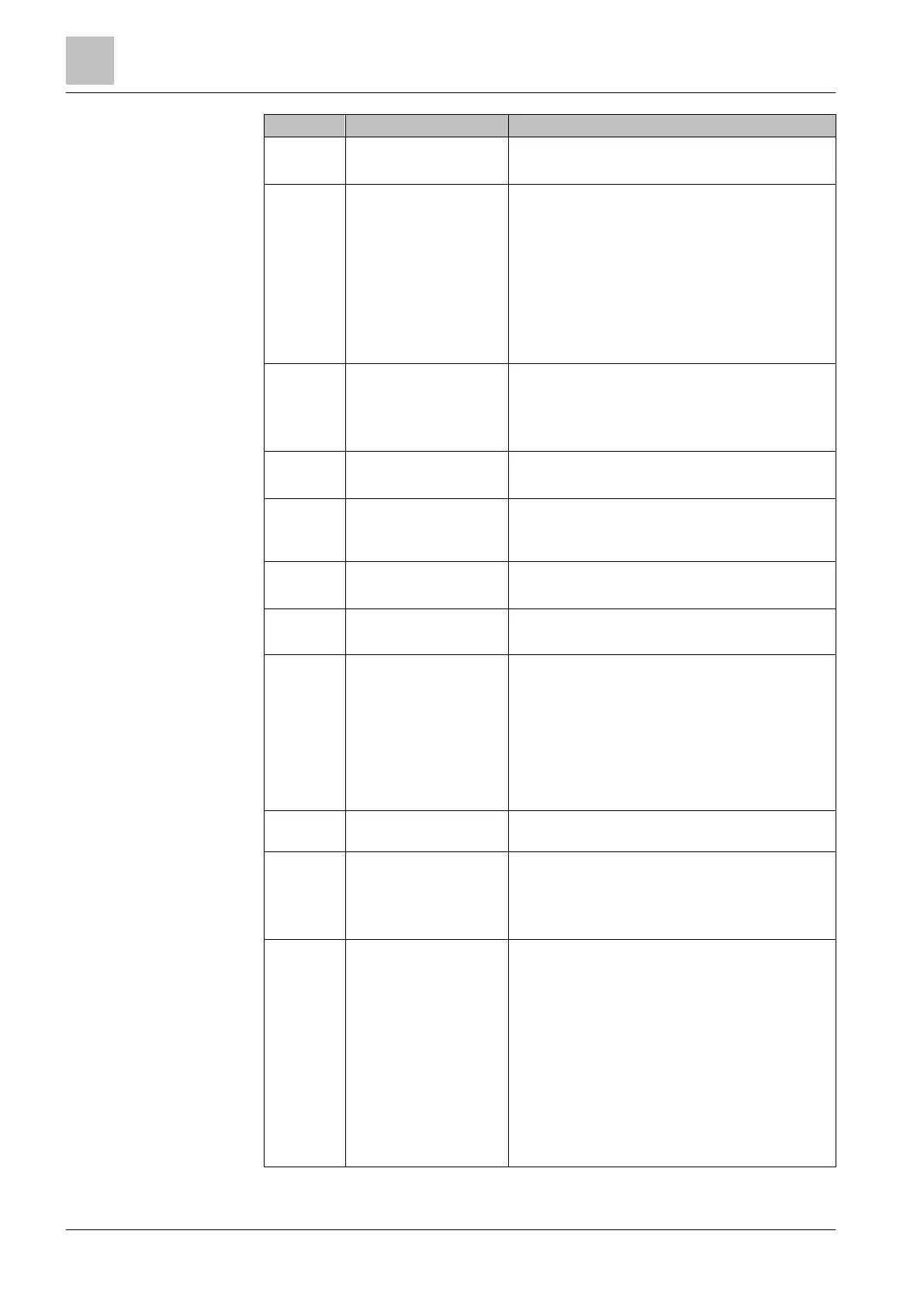

F01662 CU hardware fault

1. Switch the CU off and on again.

2.

Update the firmware.

3. Contact Technical Support.

A01910

F01910

Setpoint timeout: p2040 ≠ 0

ms and one of the following

causes:

● The bus connection is

interrupted

● The MODBUS master

is switched off

● Communications error

(CRC, parity bit, logical

error)

1. Establish the bus connection and switch on the

communication partners.

Possibly adapt p2040.

Set the PROFIBUS master to RUN.

F03505 Analog input, wire break

1. Check the connection with the signal source for

interruptions.

Check the level of the signal which is fed in.

The input current measured by the analog input can be

read in r0752.

F06310 Supply voltage (p0210)

incorrectly parameterized

1. Check the supply voltage and change the parameter

(p0210), if necessary.

2. Check the line voltage.

F07011 Motor overtemperature

1. Reduce the motor load.

2.

Check the ambient temperature and the motor

ventilation.

3. Check the wiring and the connection of the sensor.

F07016 Motor temperature sensor

fault

1. Check that the sensor is correctly connected.

2.

Check the parameter assignment (p0601).

3. Switch off the temperature sensor error (p0607 = 0).

F07086

F07088

Switching over units:

Parameter limit violation

Check the adapted parameter value and correct it, if

necessary.

F07320 Automatic restart aborted

1. Increase the number of restart attempts (p1211). The

actual number of start attempts is shown in r1214.

Increase the waiting time in p1212 or the monitoring

time in p1213.

Apply the ON command (p0840).

Increase the monitoring time of the power unit or

disable the monitoring time (p0857).

Reduce the waiting time for resetting the fault

counter p1213[1] so that fewer faults are registered

F07330 Search current measured

too low

1. Increase the search current (p1202).

2.

Check that the motor is correctly connected.

F07426 Technology controller

actual value limited

The actual value for the technology controller which is

interconnected via connector input p2264 has reached a

limit.

Adjust the limits to the signal level (p2267, p2268).

2. Check the actual value (p2264).

F07801 Motor overcurrent The permissible motor limit current has been exceeded.

Check the current limits (p0640).

Vector control: Check the settings for the current

controller (p1715, p1717).

V/f control: Check the settings for the current limiting

controller (p1340…p1346).

Increase the up ramp (p1120) or reduce the load.

Check the motor and the motor cables for short-

circuits or ground faults.

Check the motor for star-delta connection and rating

plate parameterization.

Check the combination of the power unit and motor.

Select the flying restart function (p1200) if switched

Loading...

Loading...