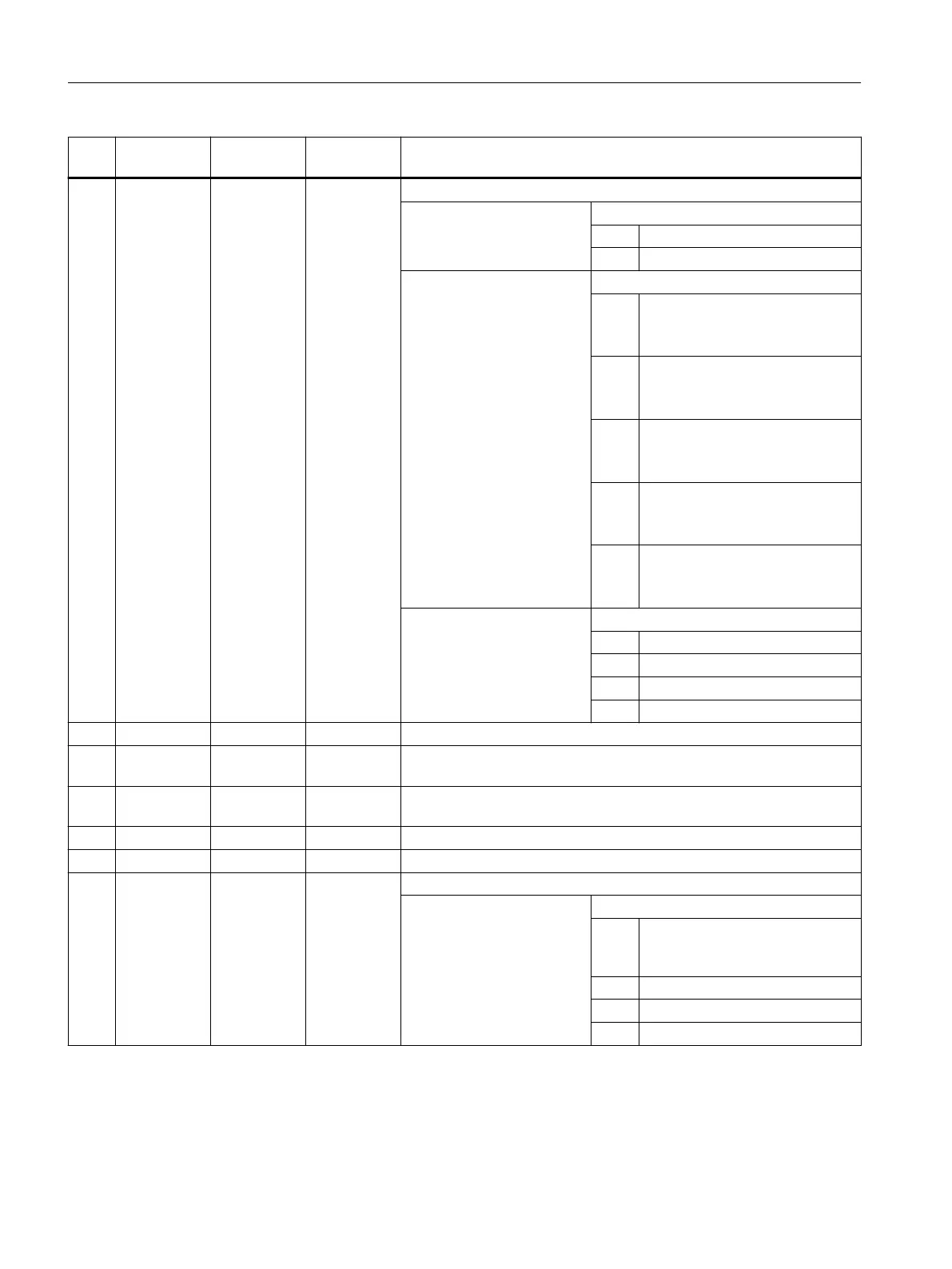

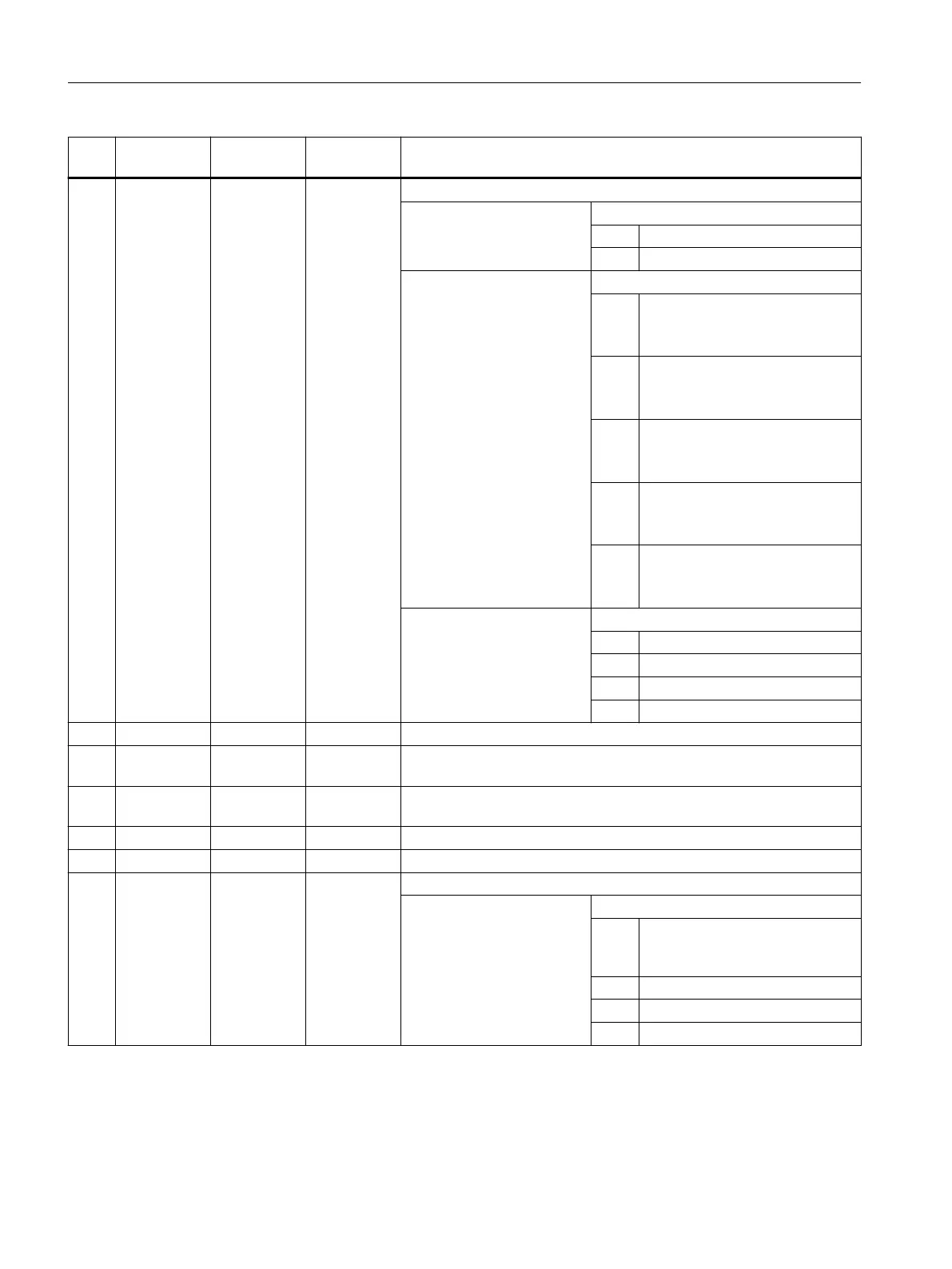

No. Parameter

mask

Parameter

internal

Data type Meaning

5 <_VARI> INT Machining type

UNITS: Form-truing type

1 = Parallel to the axis

2 = Parallel to the contour

TENS: Machining direction

0 = Pulling

Possible with cutting edge posi‐

tions 1 to 4

1 = Pushing

Possible with cutting edge posi‐

tions 1 to 4

2 = Alternating

Possible with cutting edge posi‐

tions 1 to 8

3 = Start → end

Possible with cutting edge posi‐

tions 1 to 8

4 = End → start

Possible with cutting edge posi‐

tions 1 to 8

HUNDREDS: Infeed direction

1 = Infeed X for G18 or Y- for G19

2 = Infeed X+ for G18 or Y+ for G19

3 = Infeed Z- for G18 and for G19

4 = Infeed Z+ for G18 and for G19

6 <_D> REAL Dressing value for form-truing type parallel to the axis

7 <_DX> REAL Dressing value X for G18 or Y for G19 for form-truing type parallel to the

contour

8 <_DZ> REAL Dressing value Z for G18 and G19 for form-truing type parallel to the

contour

9 <S_PA> REAL Form-truing allowance

10 <S_N> INT Number of strokes in the form-truing program

11 <_DMODE> INT Display mode

UNITS: Machining plane G17/G18/G19

0 = Compatibility, the plane effective

before the cycle call remains ac‐

tive

1 = G17 (only active in the cycle)

2 = G18 (only active in the cycle)

3 = G19 (only active in the cycle)

Work preparation

3.25 Programming cycles externally

NC programming

1090 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...