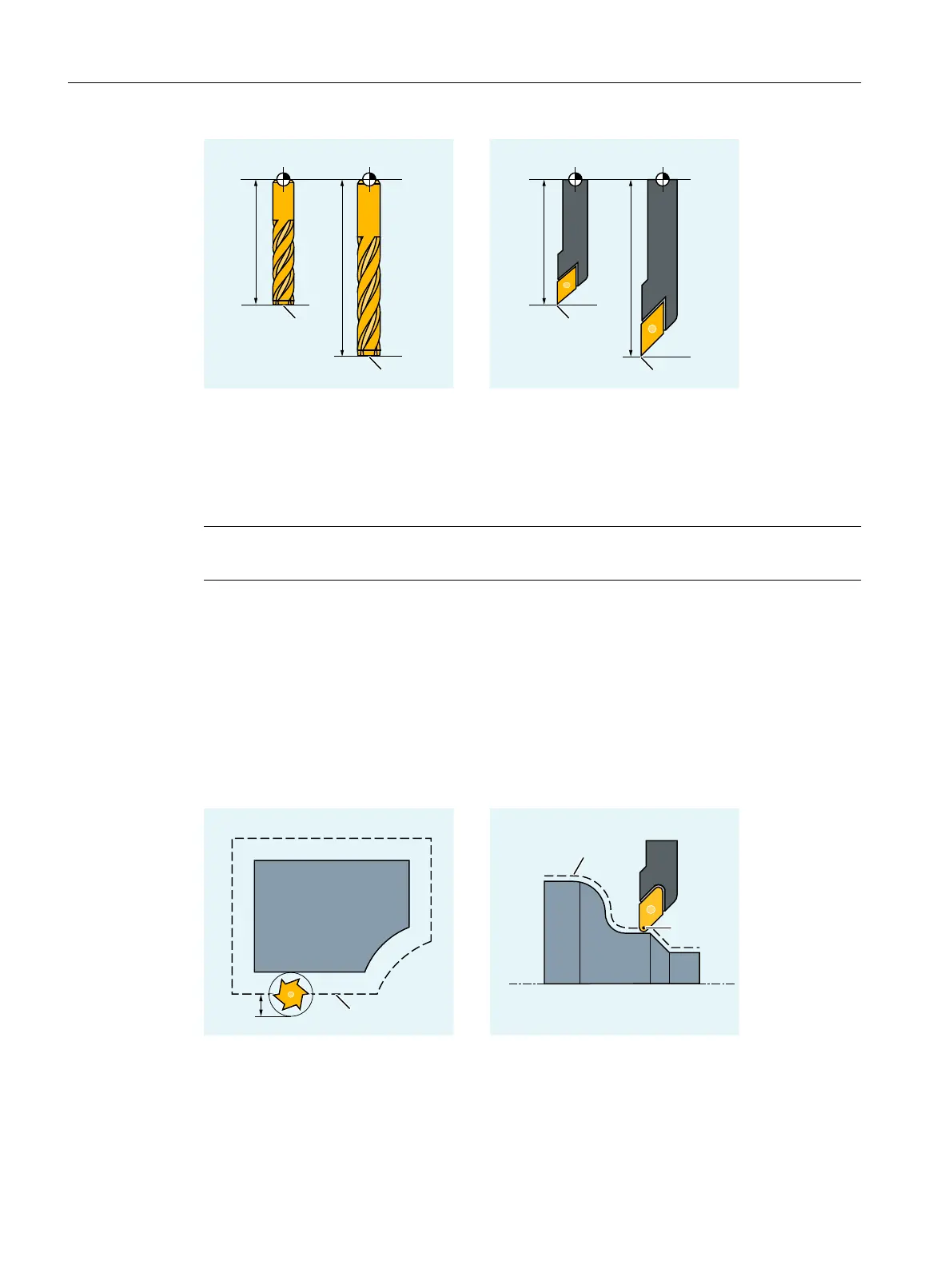

T Tool carrier reference point

P Tool tip

This length is measured and entered in the tool compensation memory of the control together

with definable wear values. From this data, the control calculates the traversing movements in

the infeed direction.

Note

The correction value of the tool length depends on the spatial orientation of the tool.

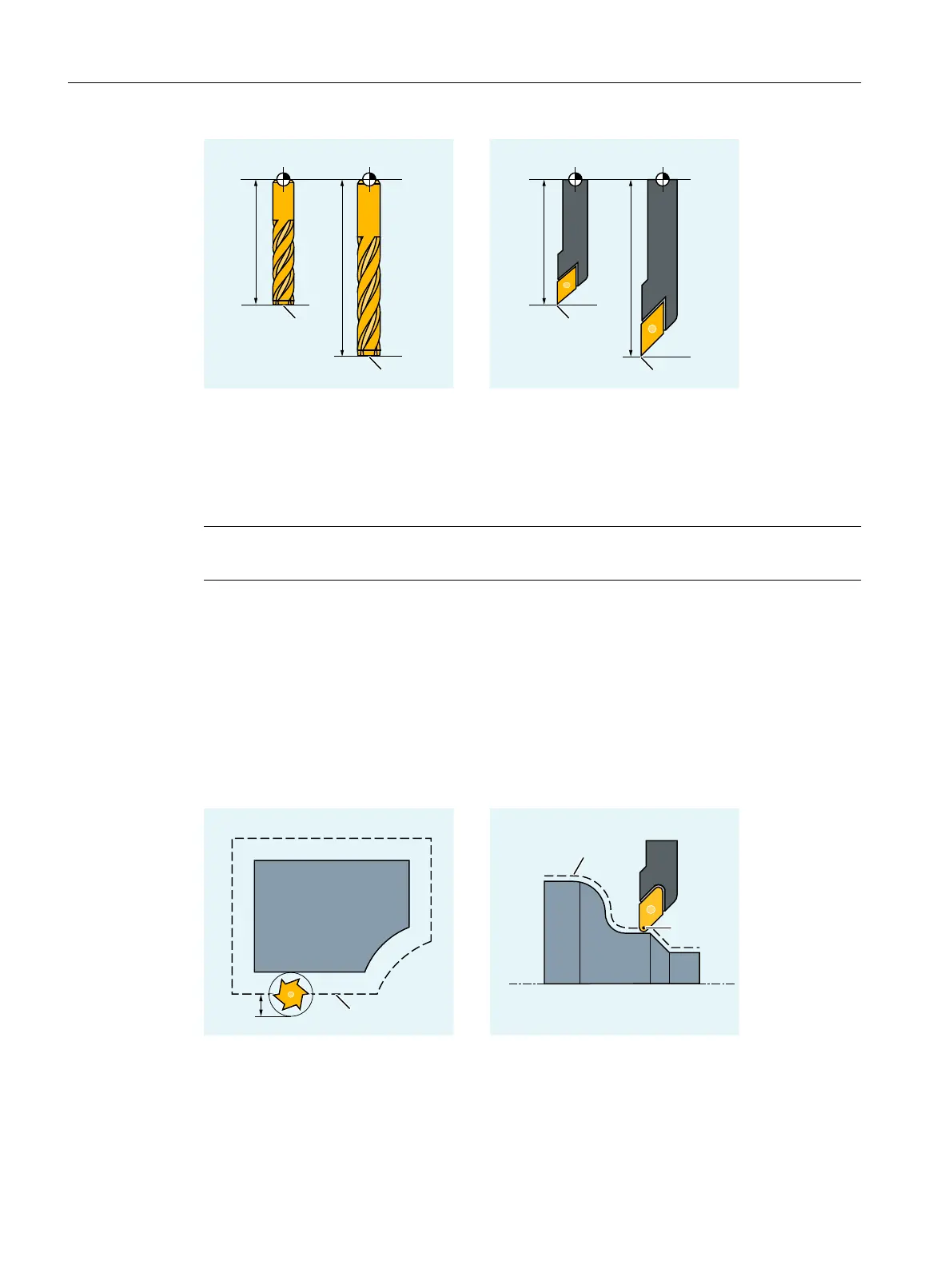

2.5.3 Tool radius compensation

The contour and tool path are not identical. The milling tool or cutting edge center point must

travel along a path corresponding to the tool radius that is equidistant from the contour (tool

center point path). To do this, while executing the program, the control shifts the programmed

tool center point path – based on the radius of the active tool (tool offset memory) – so that the

tool cutting edge traverses precisely along the programmed contour.

R Tool radius

S Cutting edge center point

The tool radius compensation is described in detail in the "Tool radius compensation

(Page 251)" Chapter.

Fundamentals

2.5 Tool offsets

NC programming

68 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...