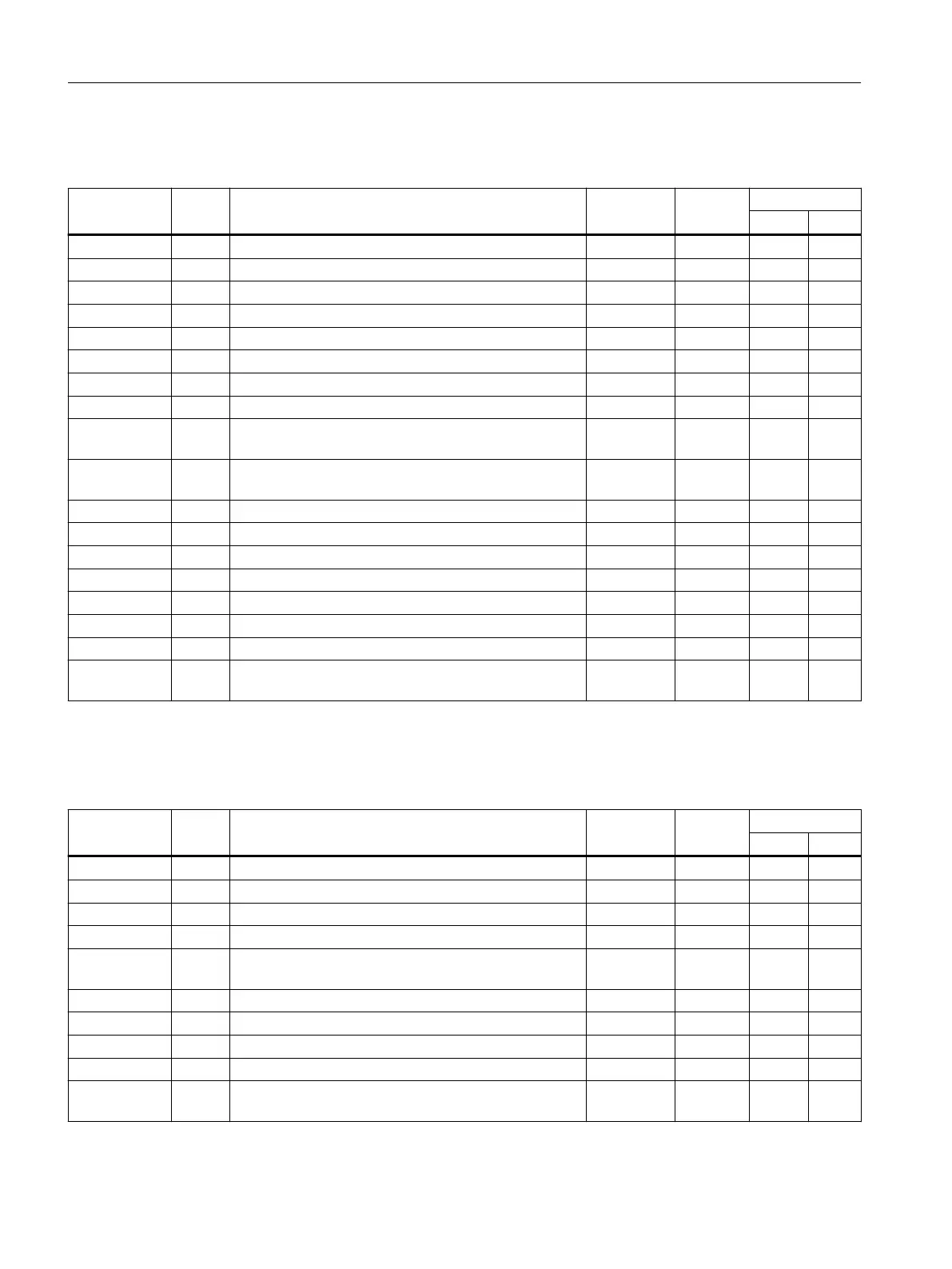

4.3.3 G group 2: Non-modally valid motion, dwell time

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

G4 1 Dwell time, preset - s

G63 2 Tapping without synchronization - s

G74 3 Reference point approach with synchronization - s

G75 4 Fixed-point approach - s

REPOSL 5 Linear repositioning - s

REPOSQ 6 Repositioning in a quadrant - s

REPOSH 7 Repositioning in semicircle - s

REPOSA 8 Linear repositioning with all axes - s

REPOSQA 9 Linear repositioning with all axes, geometry axes in

quadrant

- s

REPOSHA 10 Repositioning with all axes; geometry axes in semicir‐

cle

- s

G147 11 Approach contour with straight line - s

G247 12 Approach contour with quadrant - s

G347 13 Approach contour with semicircle - s

G148 14 Leave contour with straight line - s

G248 15 Leave contour with quadrant - s

G348 16 Leave contour with semicircle - s

G5 17 Oblique plunge-cut grinding - s

G7 18 Compensatory motion during oblique plunge-cut grind‐

ing

- s

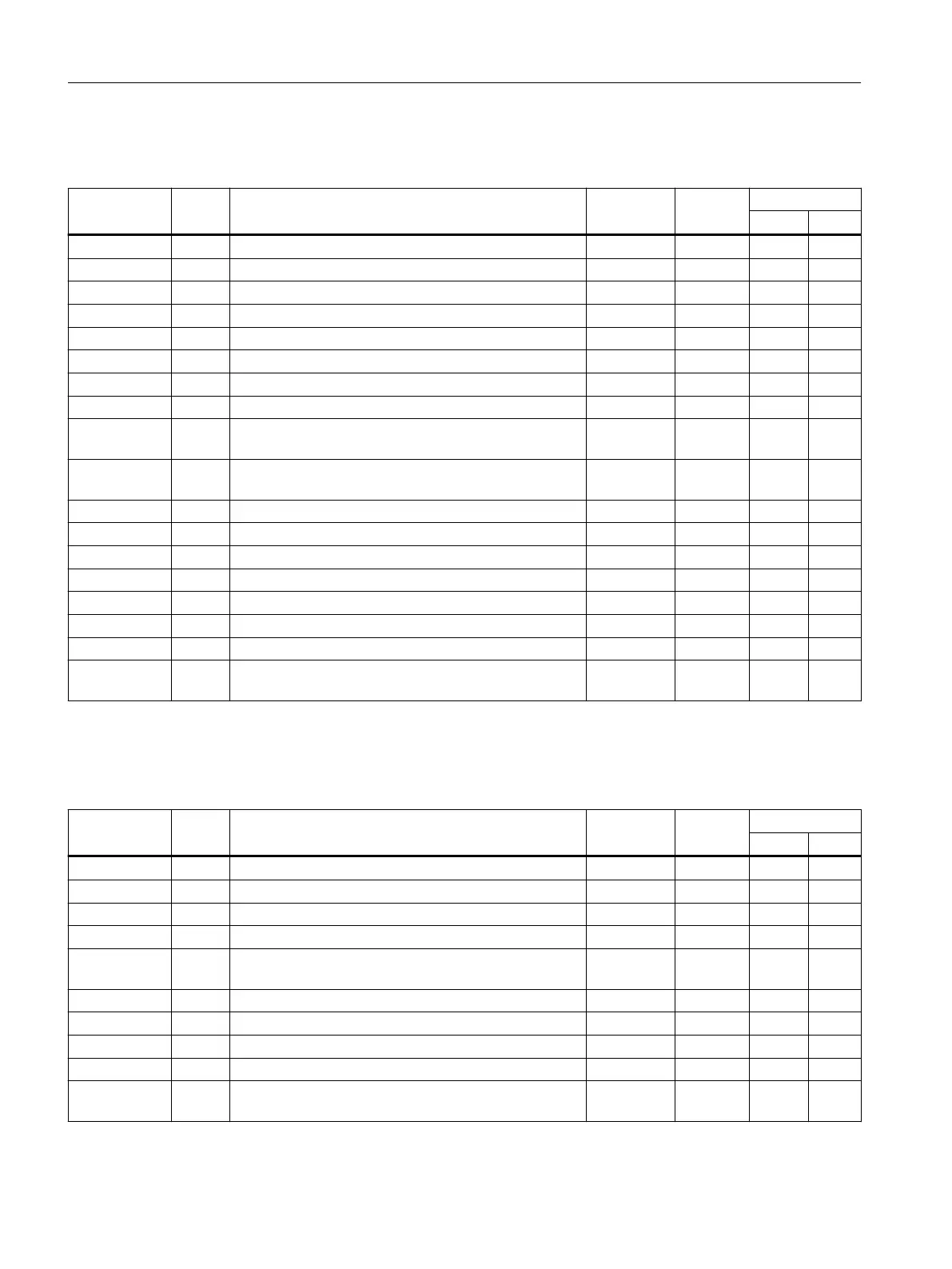

4.3.4 G group 3: Programmable frame, working area limitation and pole programming

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

TRANS 1 TRANSLATION: Programmable offset - s

ROT 2 ROTATION: Programmable rotation - s

SCALE 3 SCALE: Programmable scaling - s

MIRROR 4 MIRROR: Programmable mirroring - s

ATRANS 5 Additive TRANSLATION: Additive programmable

translation

- s

AROT 6 Additive ROTATION: Programmable rotation - s

ASCALE 7 Additive SCALE: Programmable scaling - s

AMIRROR 8 Additive MIRROR: Programmable mirroring - s

- 9 Unassigned - -

G25 10 Minimum working area limitation/spindle speed limita‐

tion

- s

Tables

4.3 G commands

NC programming

1248 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...