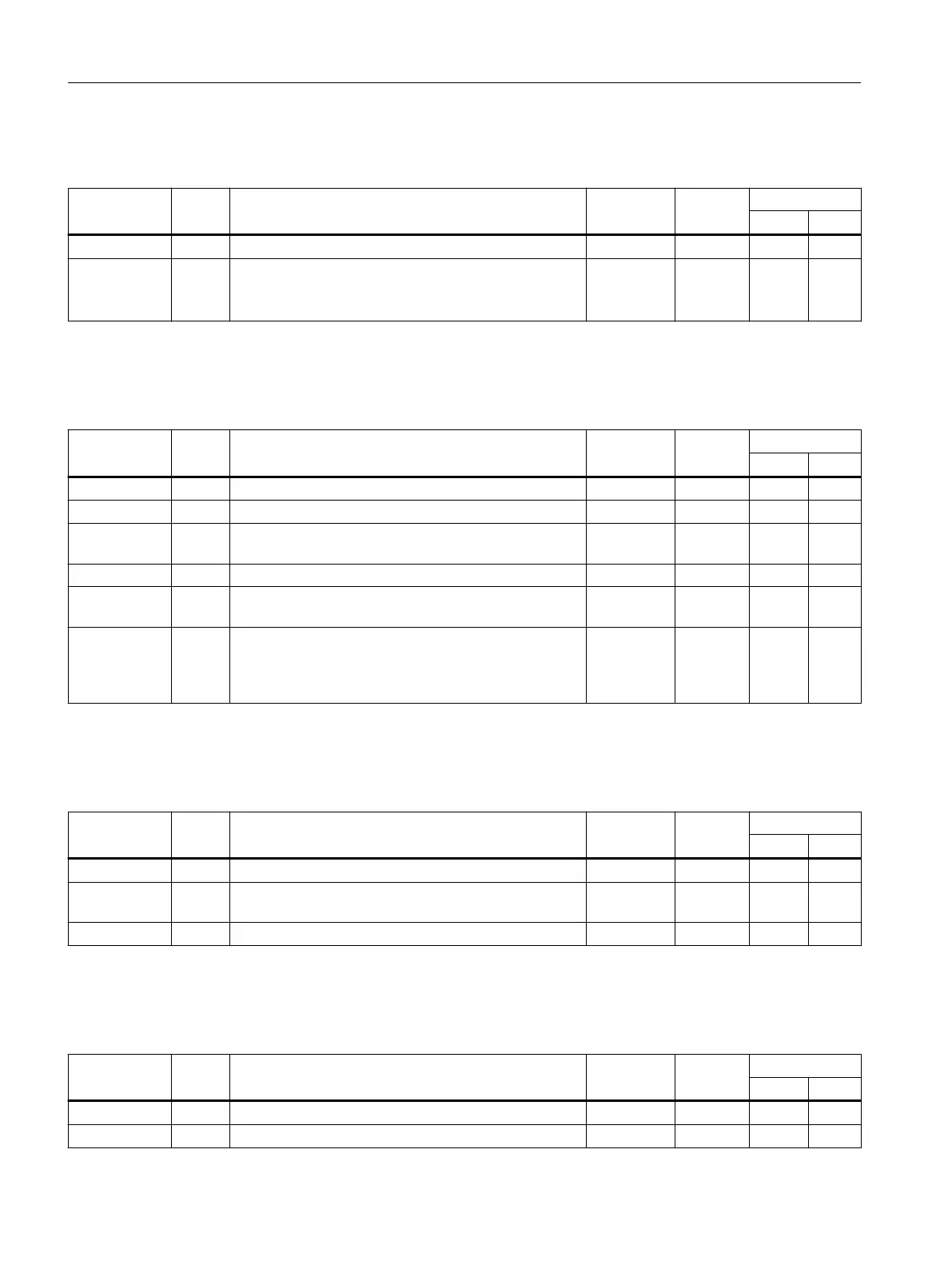

4.3.55 G group 55: Rapid traverse with/without linear interpolation

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

RTLION 1 Rapid traverse motion with linear interpolation ON + m x

RTLIOF 2 Rapid traverse motion with linear interpolation OFF

Rapid traverse motion is achieved with single-axis in‐

terpolation.

+ m

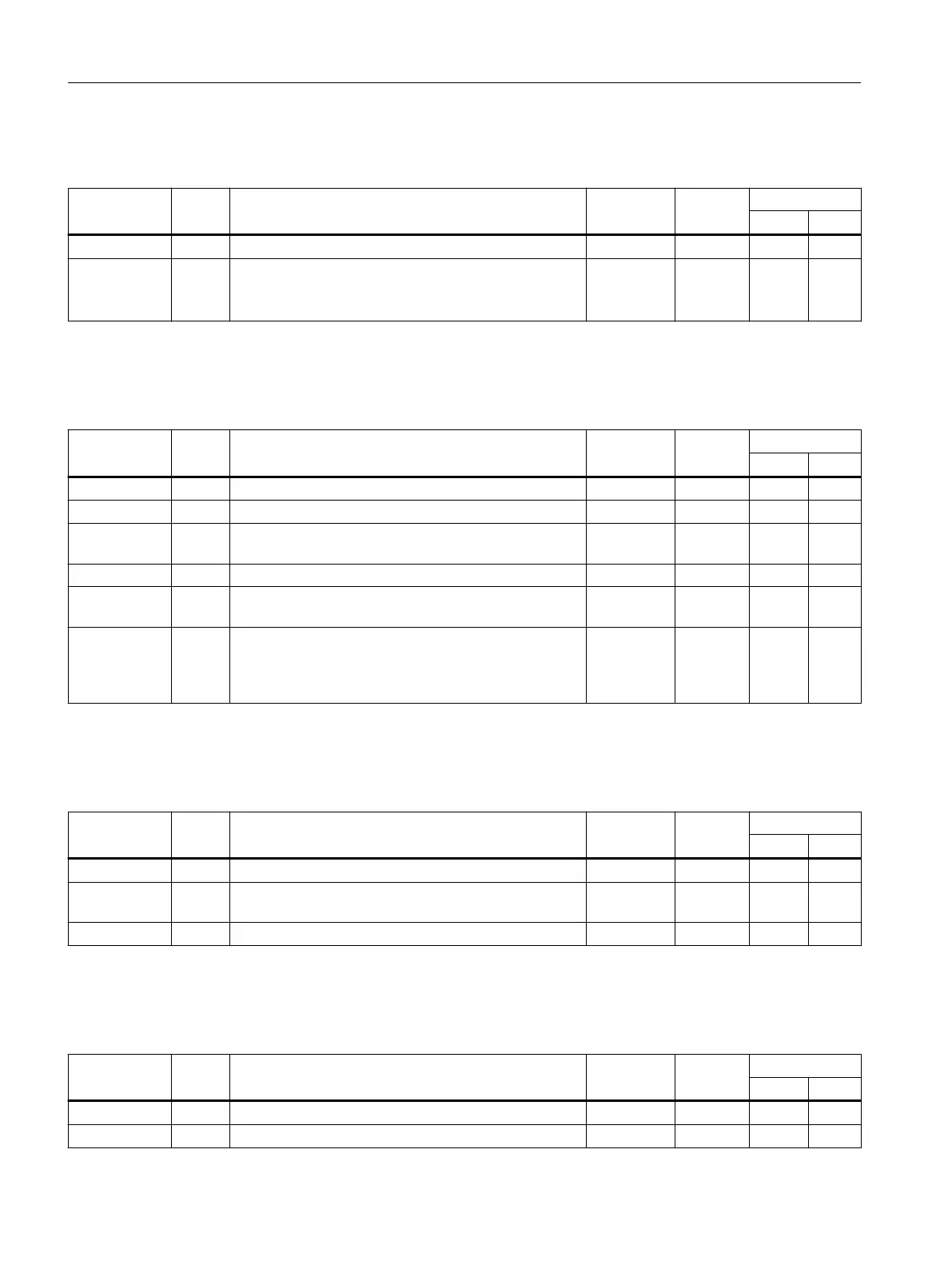

4.3.56 G group 56: Taking into account tool wear

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

TOWSTD 1 Initial setting value for offsets in tool length + m x

TOWMCS 2 Wear values in the machine coordinate system (MCS) + m

TOWWCS 3 Wear values in the workpiece coordinate system

(WCS)

+ m

TOWBCS 4 Wear values in the basic coordinate system (BCS) + m

TOWTCS 5 Wear values in the tool coordinate system (toolholder

ref. point T at the toolholder)

+ m

TOWKCS 6 Wear values in the coordinate system of the tool head

for kinetic transformation

(differs from machine coordinate system through tool

rotation)

+ m

4.3.57 G group 57: Corner deceleration

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

FENDNORM 1 Corner deceleration OFF + m x

G62 2 Corner deceleration at inside corners when tool radius

compensation is active (G41/G42)

+ m

G621 3 Corner deceleration at all corners + m

4.3.58 G group 59: Dynamic response mode for path interpolation

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

DYNNORM 1 Standard dynamic response + m x

DYNPOS 2 Positioning mode, tapping + m

Tables

4.3 G commands

NC programming

1264 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...