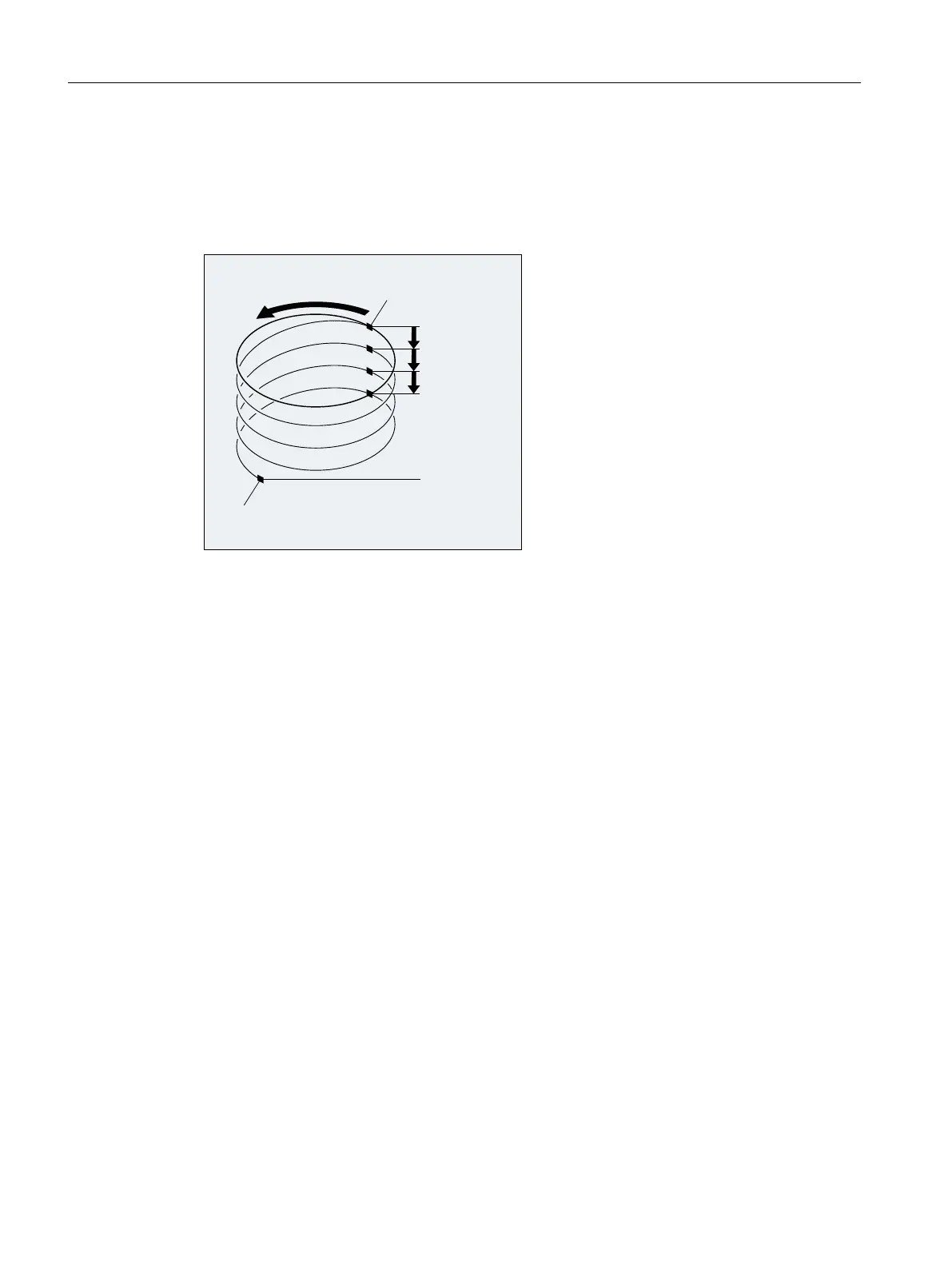

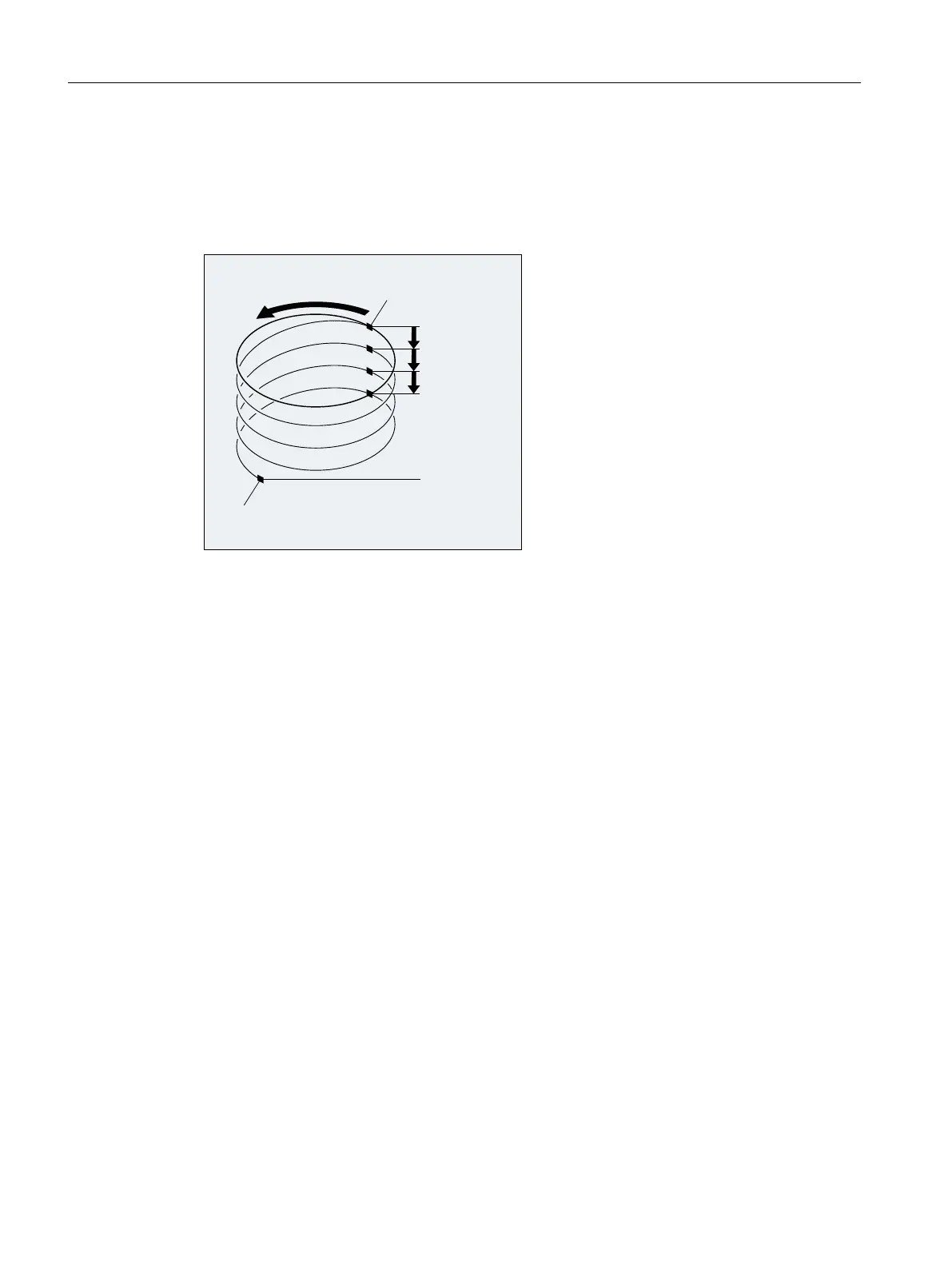

3. Approach circle end position, e.g. as part rotation.

4. Execute steps 2 and 3 across the infeed depth.

The pitch, with which the helix is to be machined is calculated from the number of full circles plus

the programmed circle end position (executed across the infeed depth).

6WDUWLQJSRLQW

)XOOFLUFOH

)XOOFLUFOH

)XOOFLUFOH

(QGSRLQWDV

SDUWLDOUHYROX

WLRQ

7DUJHWSRLQW

Programming the end point for helical interpolation

Please refer to circular interpolation for a detailed description of the interpolation parameters.

Programmed feedrate

For helical interpolation, it is advisable to specify a programmed feedrate override (CFC).

FGROUP can be used to specify which axes are to be traversed with a programmed feedrate.

For more information please refer to the Path behavior section.

2.9.8 Involute interpolation (INVCW, INVCCW)

The involute of a circle is the path taken by the end of an idealized string as it unwraps around

a curve.

Involute interpolation allows path trajectories along an involute. It is executed in the plane in

which the basic circle is defined and runs from the programmed starting point to the

programmed end point.

Fundamentals

2.9 Motion commands

NC programming

206 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...