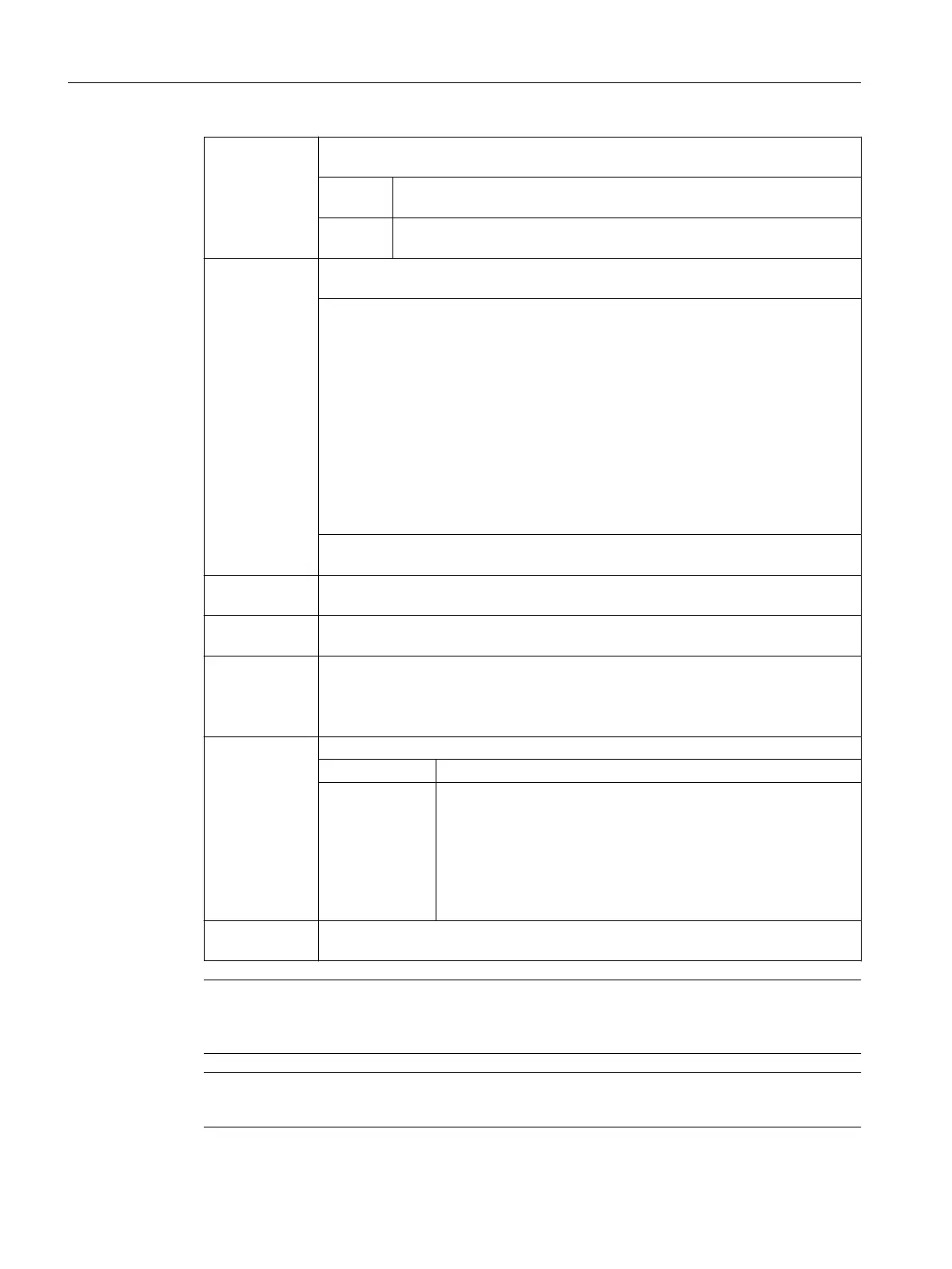

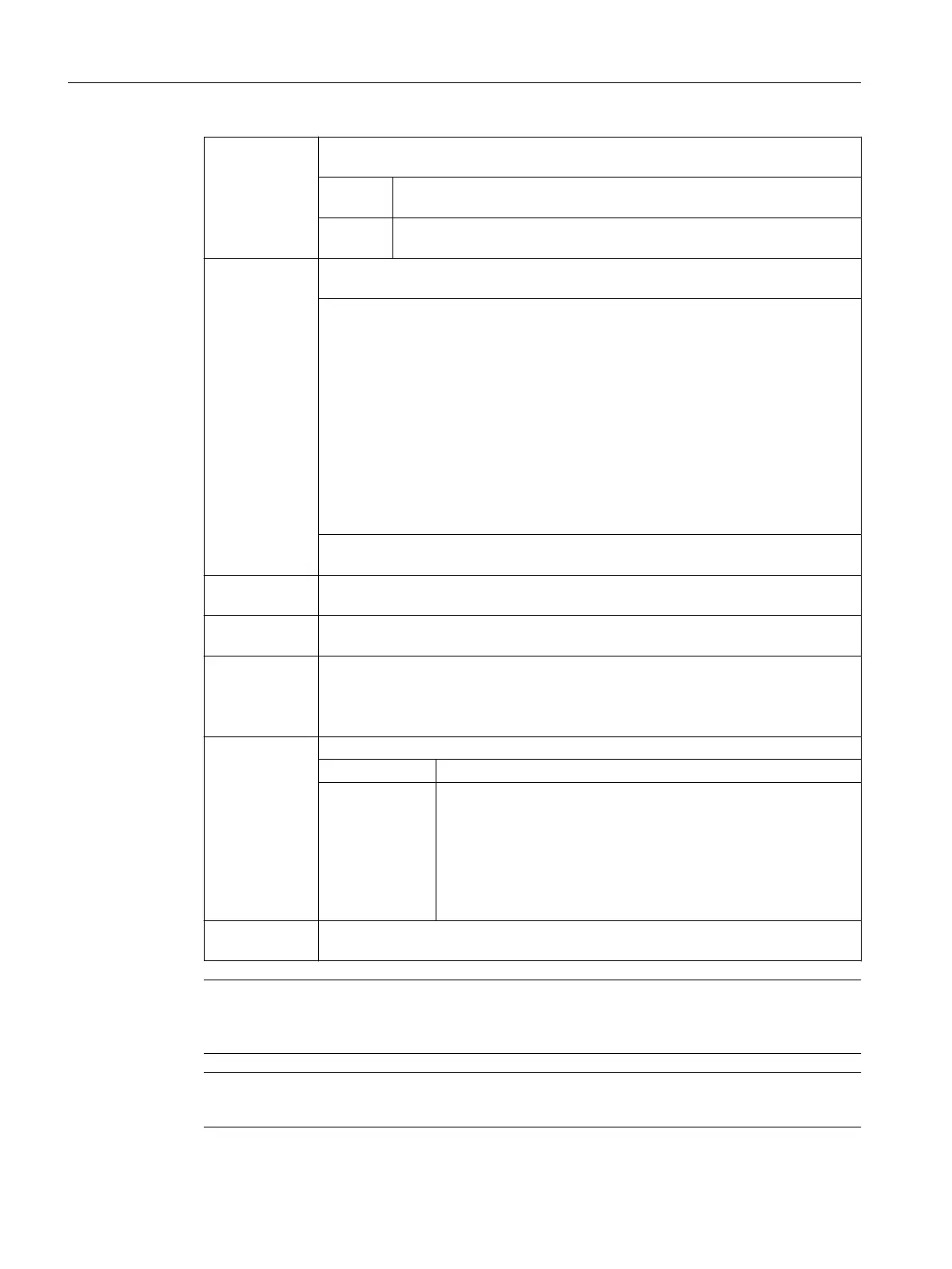

LFTXT

LFWP:

The retraction direction is controlled in conjunction with ALF with G

commands LFTXT and LFWP.

LFTXT: The plane in which the retraction motion is executed is calculated from

the path tangent and the tool direction (default setting).

LFWP: The plane in which the retraction motion is executed is the active working

plane.

ALF= : The direction is programmed in discrete degree increments with ALF in the plane of

the retraction motion.

With LFTXT, retraction in the tool direction is defined for ALF=1.

For LFWP, the direction in the machining plane is derived from following assignment:

● G17 (X/Y plane)

ALF=1 ; Retraction in the X direction

ALF=3 ; Retraction in the Y direction

● G18 (Z/X plane)

ALF=1 ; Retraction in the Z direction

ALF=3 ; Retraction in the X direction

● G19 (Y/Z plane)

ALF=1 ; Retraction in the Y direction

ALF=3 ; Retraction in the Z direction

For additional information on the programming options with ALF see Chapter "Tra‐

versing direction for fast retraction from the contour (Page 546)".

LFPOS: Retraction of the axis declared with POLFMASK or POLFMLIN to the absolute axis

position programmed with POLF.

POLFMASK: Release of axes (<axis 1 name>,<axis 1 name>, etc.) for independent

retraction to absolute position.

POLFMLIN: Release of axes for retraction to absolute position in linear relation

Note:

Depending on the dynamic response of all the axes involved, the linear relation can‐

not always be established before the lift position is reached.

POLF[]: Define absolute retraction position for the geometry axis or machine axis in the index

Effective: Modal

=<value>: In the case of geometry axes, the assigned value is interpreted as

a position in the workpiece coordinate system. In the case of ma‐

chine axes, it is interpreted as a position in the machine coordinate

system.

The values assigned can also be programmed as incremental di‐

mensions:

=IC<value>

<axis

identifier>:

Identifier of a geometry axis or machine axis.

Note

LFON or LFOF can always be programmed, but the evaluation is performed exclusively during

thread cutting (G33).

Note

POLF with POLFMASK/POLFMLIN are not restricted to thread cutting applications.

Fundamentals

2.9 Motion commands

NC programming

232 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...