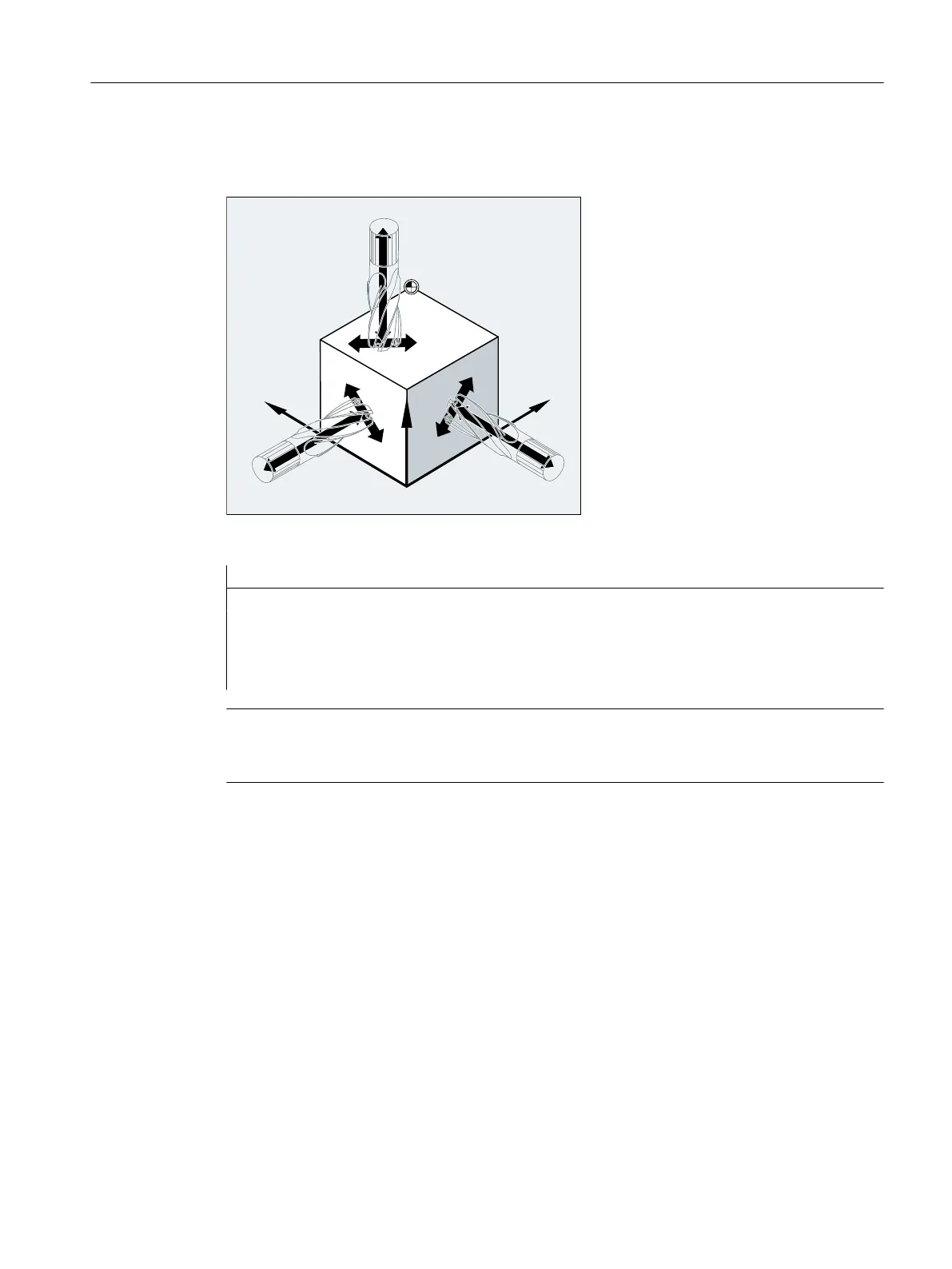

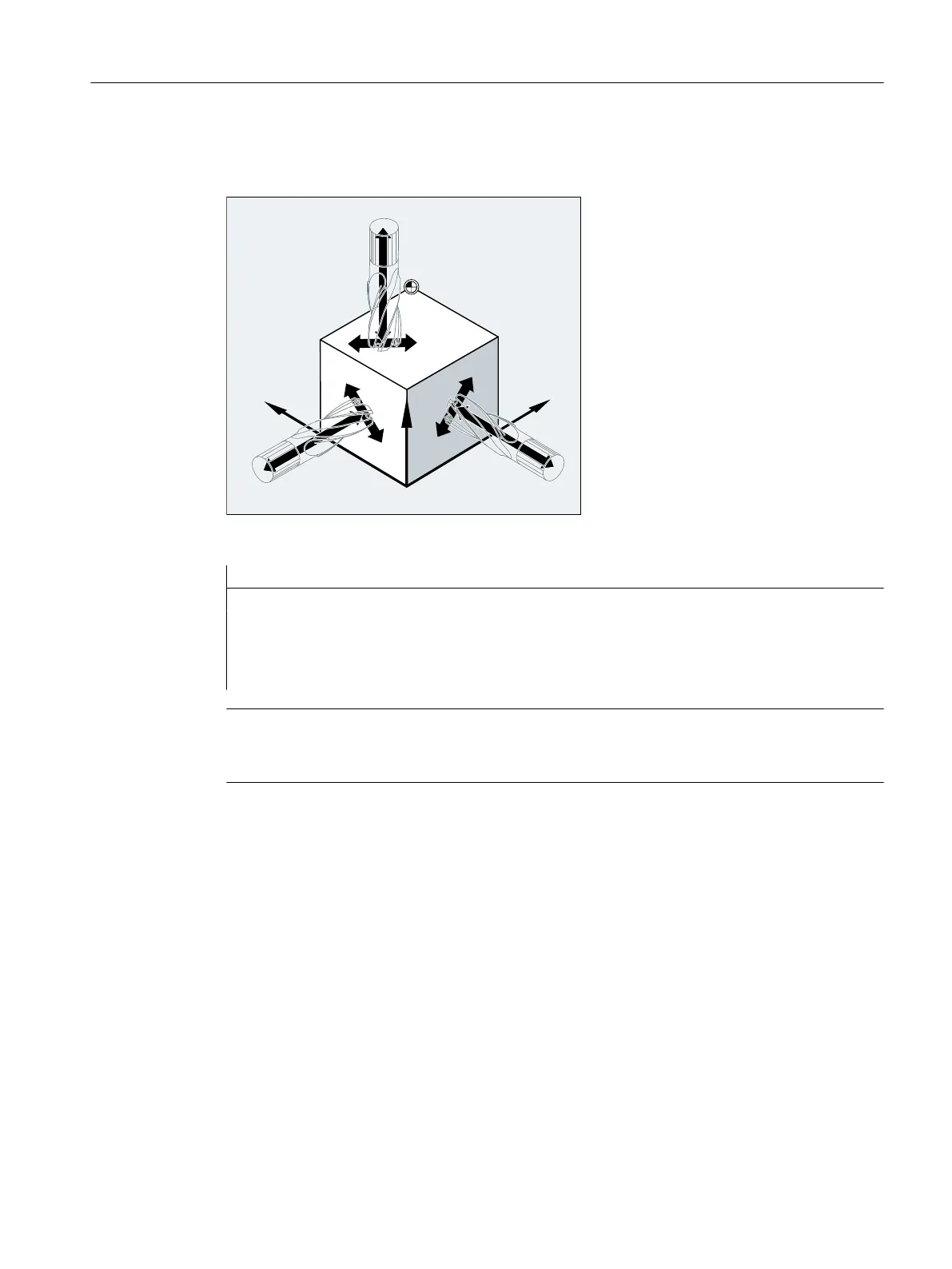

From this information, the control detects the plane and therefore the axis directions in which

it is corrected.

/HQJWK

/HQJWK

5DGLXV

5DGLXV

5DGLXV

=

;

<

Example: Milling tool

Program code Comment

...

N10 G17 G41 … ; The tool radius compensation is performed in the X/Y

plane, the tool length compensation is performed in the Z

direction.

...

Note

On 2-axis machines, tool radius compensation is only possible in "real" planes, usually

with G18.

Tool length compensation

The wear parameter assigned to the diameter axis on tool selection can be defined as the

diameter value using an MD. This assignment is not automatically altered when the plane is

subsequently changed. To do this, the tool must be selected again after the plane change.

Turning:

Fundamentals

2.10 Tool radius compensation

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 257

Loading...

Loading...