Additional information

Adapter transformation/toolholder with orientation capability/kinematic transformation

Any rotations and component exchanges initiated by the adapter transformation, toolholder

with orientation capability and kinematic transformation, are part of the tool environment. They

are thus always performed, even if the corresponding length component is not supposed to be

included. If this is undesirable, tool environments must be defined, in which the corresponding

transformations are not active. In many cases (i.e. any time a transformation or toolholder with

orientation capability is not used on a machine), the data sets stored for the tool environments

automatically fulfill these conditions, with the result that the user does not need to make special

provision.

Turning and grinding tools: Calculating the tool length depending on MD20360

$MC_TOOL_PARAMETER_DEF_MASK

The following machine data defines how the wear and tool length are to be evaluated if a

diameter axis is used for turning and grinding tools.

MD20360 $MC_TOOL_PARAMETER_DEF_MASK (definition of tool parameters).

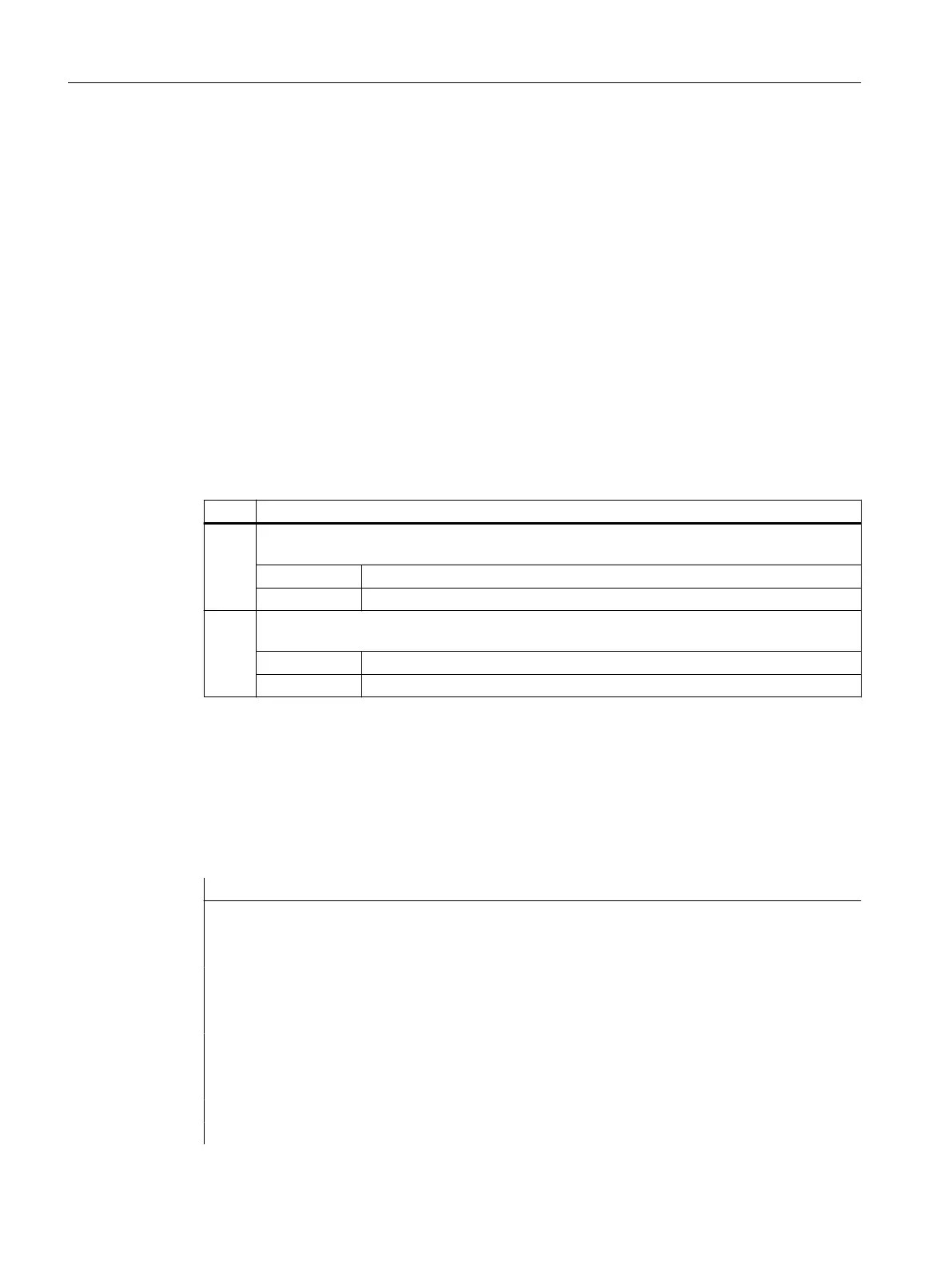

Bit Value

0

For turning and grinding tools, the wear parameter of the transverse axis is taken into account

as the diameter value:

= 0 (default) No

= 1 Yes

1 For turning and grinding tools, the tool length component of the transverse axis is taken into

account as the diameter value:

= 0 (default) No

= 1 Yes

If the bits involved are set, the associated entry is weighted with a factor of 0.5. This weighting

is reflected in the tool length returned by GETTCOR.

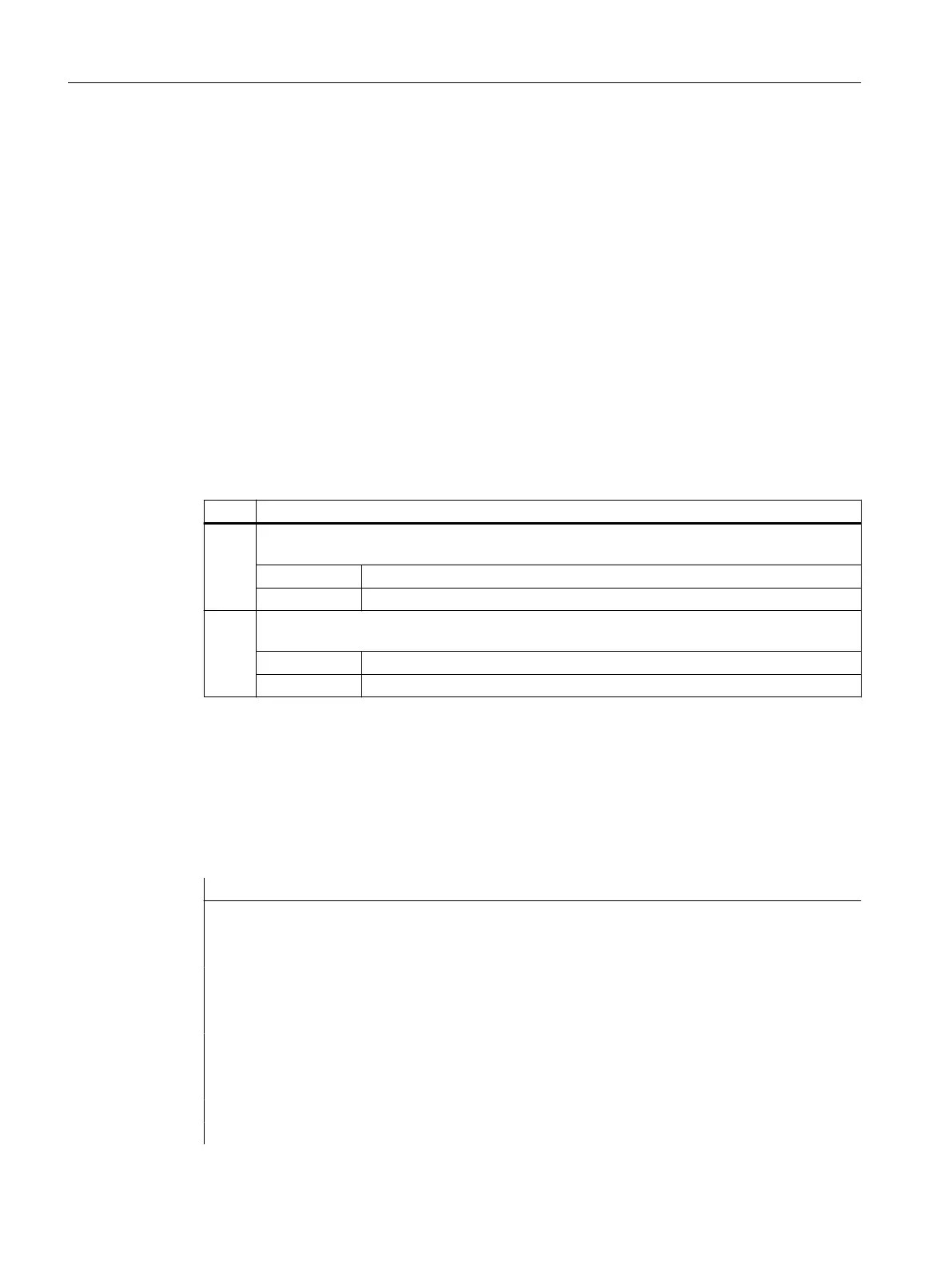

Example:

MD20360 $MC_TOOL_PARAMETER_DEF_MASK = 3

MD20100 $MC_DIAMETER_AX_DEF (geometry axis with transverse axis function) = "X"

X is diameter axis (standard turning machine configuration)

Program code Comment

N30 $TC_DP1[1,1]=500

N40 $TC_DP2[1,1]=2

N50 $TC_DP3[1,1]=3.0 ; geometry L1

N60 $TC_DP4[1,1]=4.0

N70 $TC_DP5[1,1]=5.0

N80 $TC_DP12[1,1]=12.0 ; wear L1

N90 $TC_DP13[1,1]=13.0

N100 $TC_DP14[1,1]=14.0

N110 T1 D1 G18

N120 R1=GETTCOR(_LEN,"GW")

N130 R3=_LEN[2] ; 17.0 (= 4.0 + 13.0)

Work preparation

3.13 Tool offsets

NC programming

816 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...