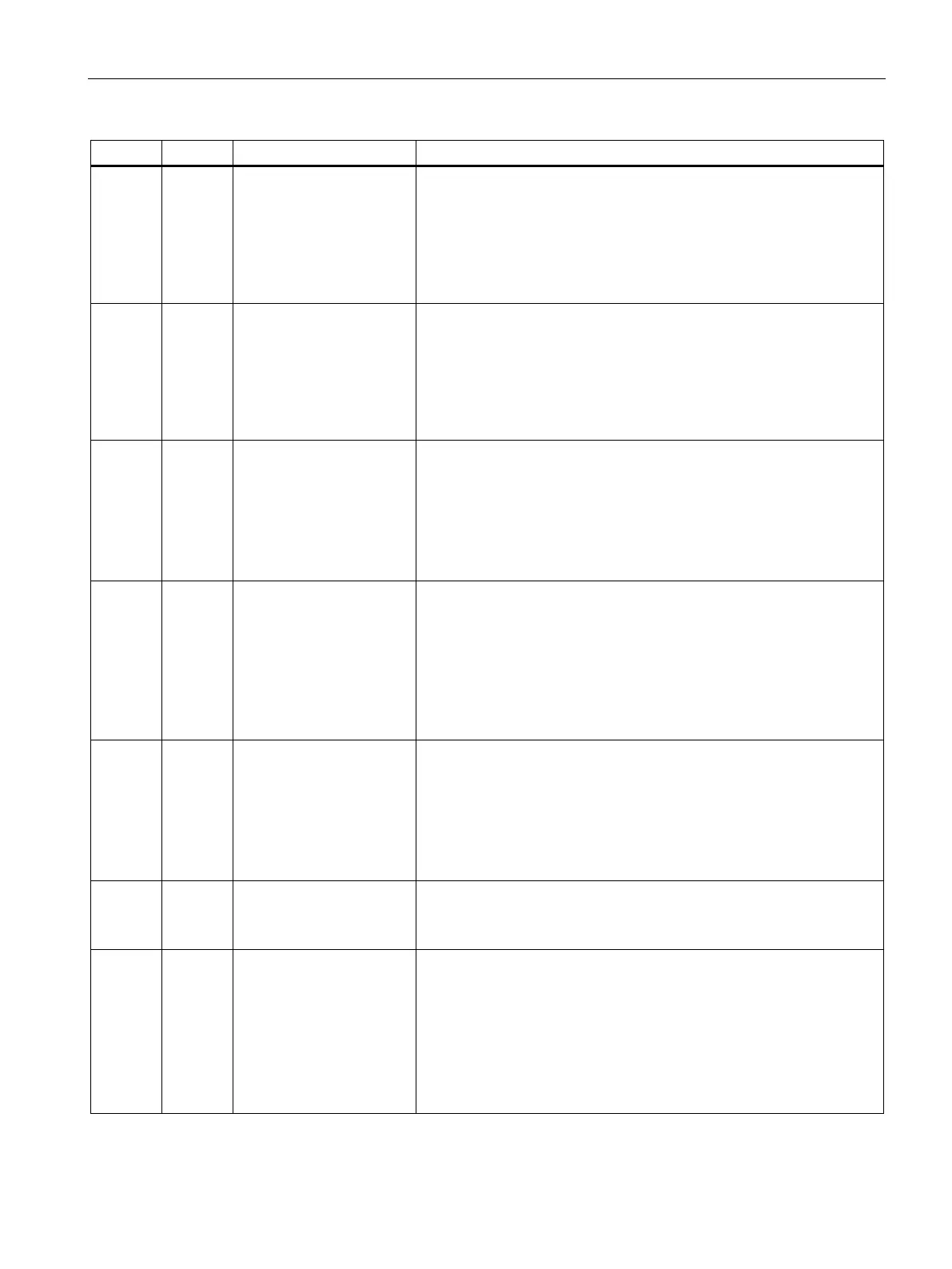

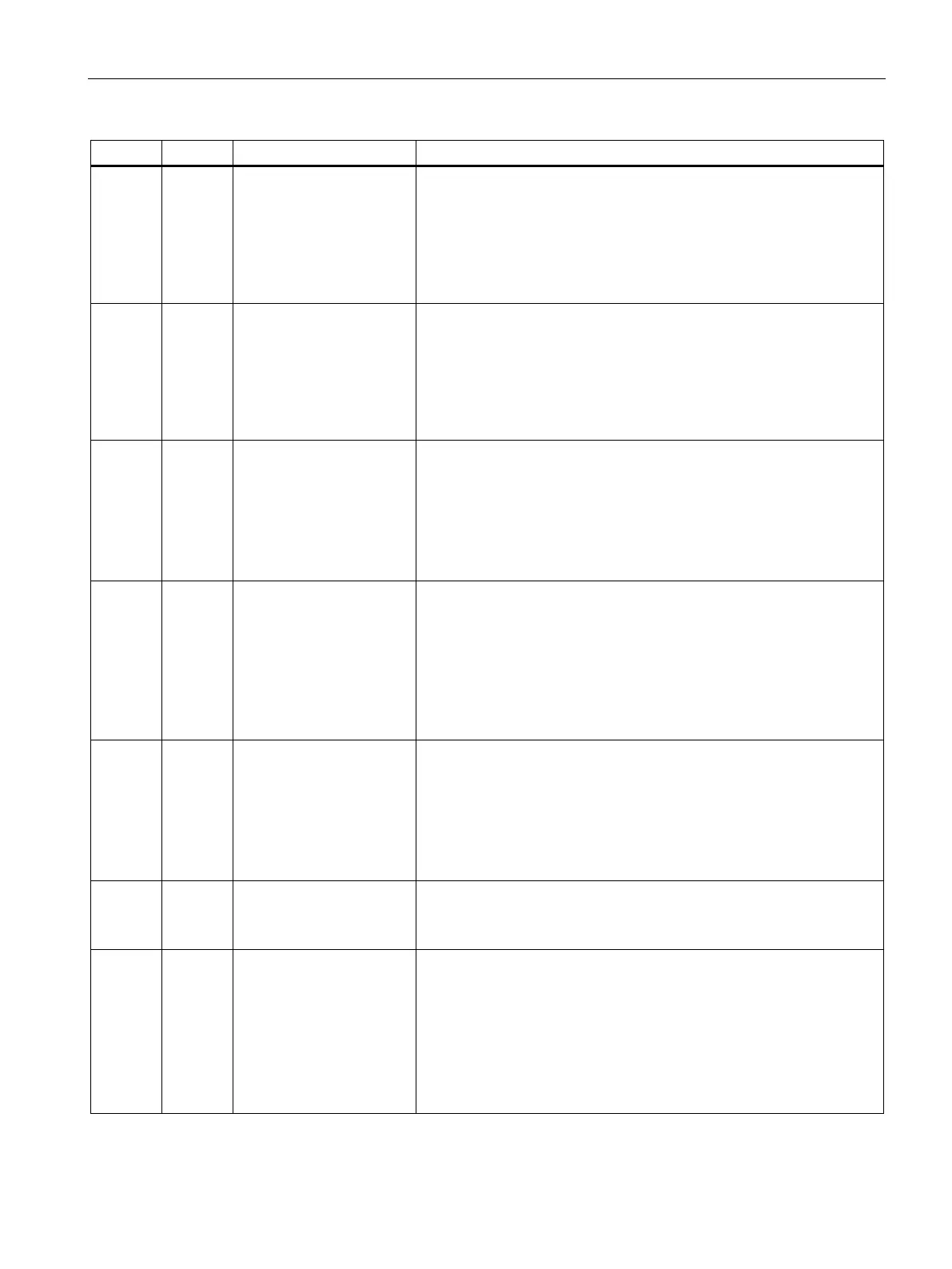

Parameters/address space

4.11 Control and feedback interface

ET 200SP F-TM Count 1x1Vpp sin/cos HF (6ES7136-6CB00-0CA0)

Equipment Manual, V1.0, 01/2021, A5E47073911-AA

65

The "Underflow Event" bit is set whenever the current count value ex-

ceeds the configured "Low Counting Limit".

• 0: No violation of limit

• 1: Low counting limit was exceeded

The "Underflow Event" bit remains set until the module's "Reset Other

Events" bit is set to 1 and remains cleared as long as the "Reset Other

The "Overflow Event" bit is set whenever the current count value ex-

ceeds the configured "High Counting Limit".

• 0: No violation of the limit

• 1: High counting limit was exceeded

The "Overflow Event" bit remains set to 1 until the module's "Reset Oth-

er Events" bit is set to 1 and remains cleared as long as the "Reset Other

The "Safe Speed Event" bit informs the safety program that a safe speed

violation has occurred.

• 0: No violation

• 1: The calculated speed, in either direction, was detected to be

greater than the configured "Speed limit"

The "Safe Speed Event" bit is cleared following an event when the "Reset

Safe Speed" bit is set to 1 in the control interface.

The "Safe Stop Event" bit informs the safety program that a safe stop

violation has occurred.

• 0: No violation

• 1: A movement was detected in either direction that exceeded the

configured "Standstill tolerance" as measured from the stored posi-

tion

The "Safe Stop Event" bit is cleared following an event when the "Reset

Safe Stop" bit is set to 1 in the control interface.

The "Safe Direction Event" bit informs the safety program that a safe

direction violation has occurred.

• 0: No violation

• 1: A movement was detected in the unsafe direction that exceeded

the configured "Monitoring tolerance"

The "Safe Direction Event" bit is cleared following an event when the

"Reset Safe Direction" bit is set to 1 in the control interface.

Current Value

This signed double integer (DINT) value shows the current count. The

position corresponds to the sign and the count value (process value).

The count value assumes values between -2147483648 and

2147483647 unless restricted by the high and low counting limits.

Measured Value

The measured value is returned as a scaled integer (DINT) value shown

as one of the following, depending upon configuration:

• Frequency is in millihertz (hertz * 1000)

• Period is in microseconds (seconds * 1000000)

• Velocity is units of measure per time base you select (velocity *

1000)

Note that negative values are reported when counting down, positive

values are reported when counting up.

Loading...

Loading...