3

03.04 Example of Operation

3.1 T

ical se

uence of o

eration

3

Ó Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Operator's Guide HMI Advanced (BAD) – 03.04 Edition 3-89

Example of Operation

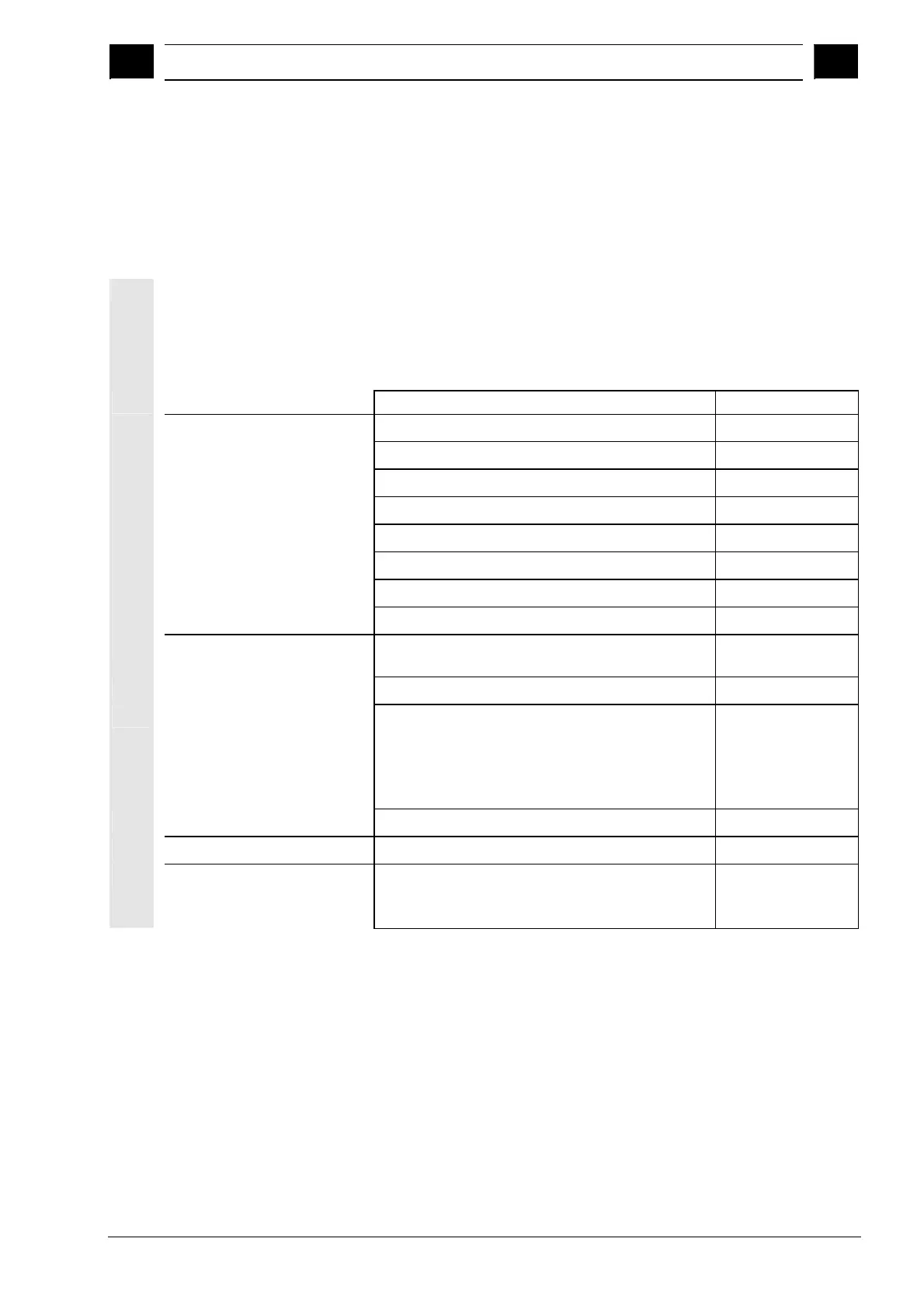

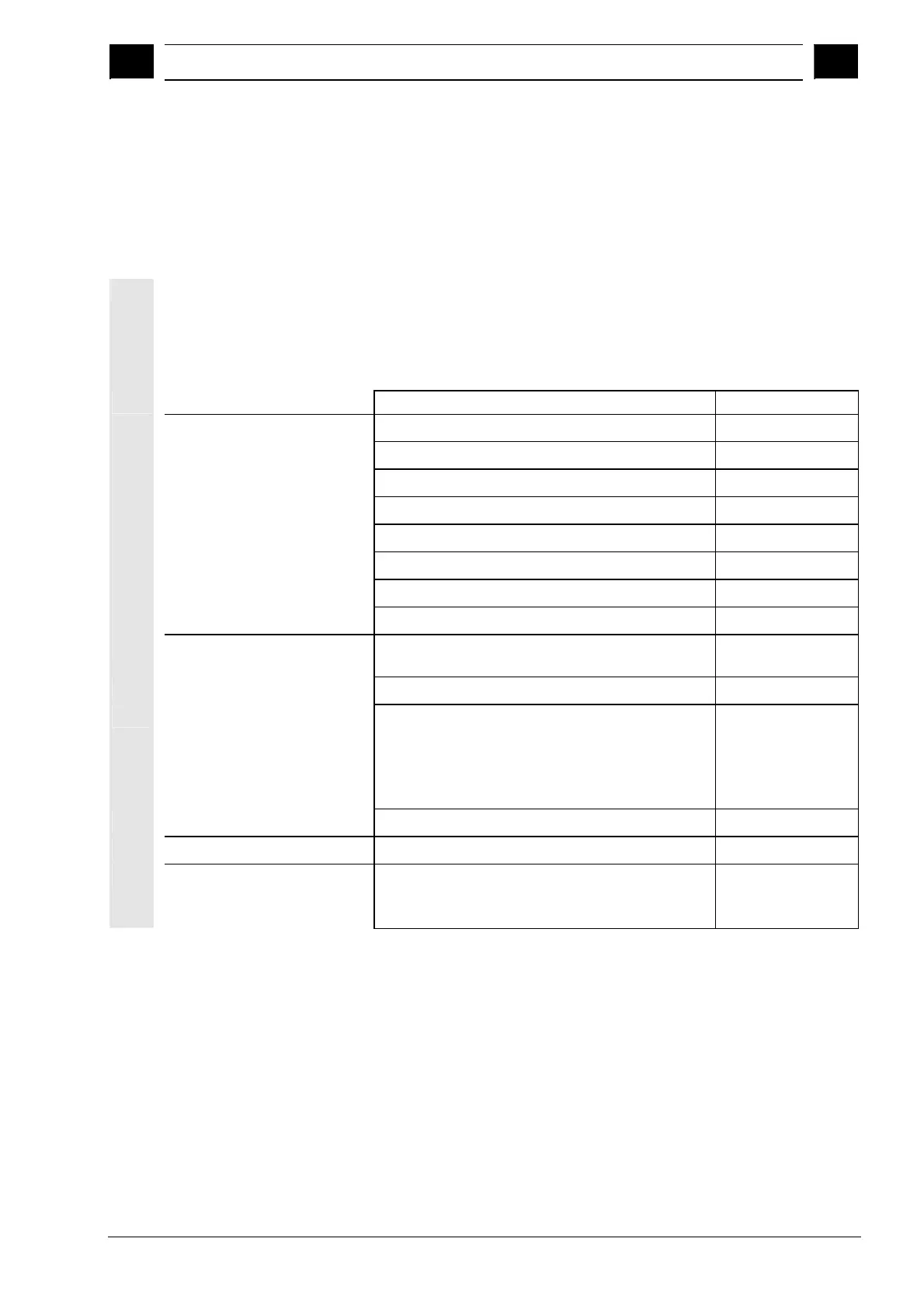

3.1 Typical sequence of operation

To provide support for entry-level users or an orientation guide for

others, this section uses a typical operating sequence (from control

system power-up to back-up of a user-generated part program) to

explain how the functions described can be located.

Step Described in Section

Setup

· Switch on machine

1.3

· Reference point approach

4.3

· Clamp workpiece/blank

· Select tools

· Define workpiece zero for coordinate inputs

· Enter tool offsets

5.2

· Calculate speeds and feedrates

4.2.4

· Define a reference point (scratching)

4.4.6

Enter/test a program

· Create a part program or read

one in via an external data interface

2.6.6

7.5.3

· Select a part program

6.10.5

· Test a program (without a tool)

· Start a part program

(e.g. in single block)

· Edit part program using program editing

function or diagnostics guide/help

4.2.1

2.4.6

4.6.7/2.6.6

8, 2.7

· Optimize a part program

6.9.5

Machine the workpiece

· Insert tool and run machining program

4.2.1

Store the program

· Save a part program

· To hard disk

· Read in/out via RS-232 interface

6.10

6.2

7.5.3/7.5.4

n

Loading...

Loading...