51

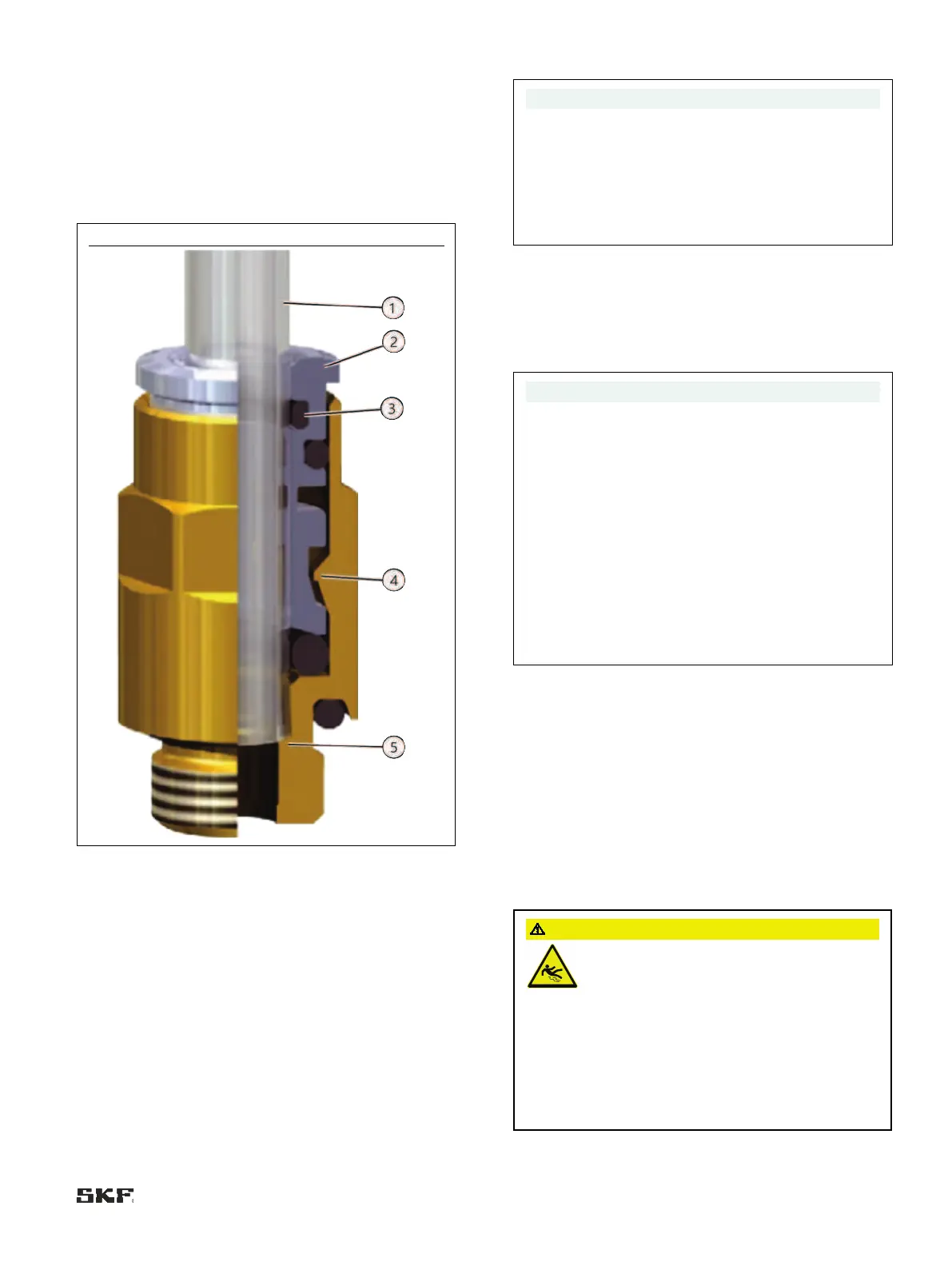

Legend to Figure 91:

1 Metal pipe

2 Collet

3 First O-ring

4 Locking claw

5 Claw groove

6 Mechanical stop

Quick coupling for plastic tube

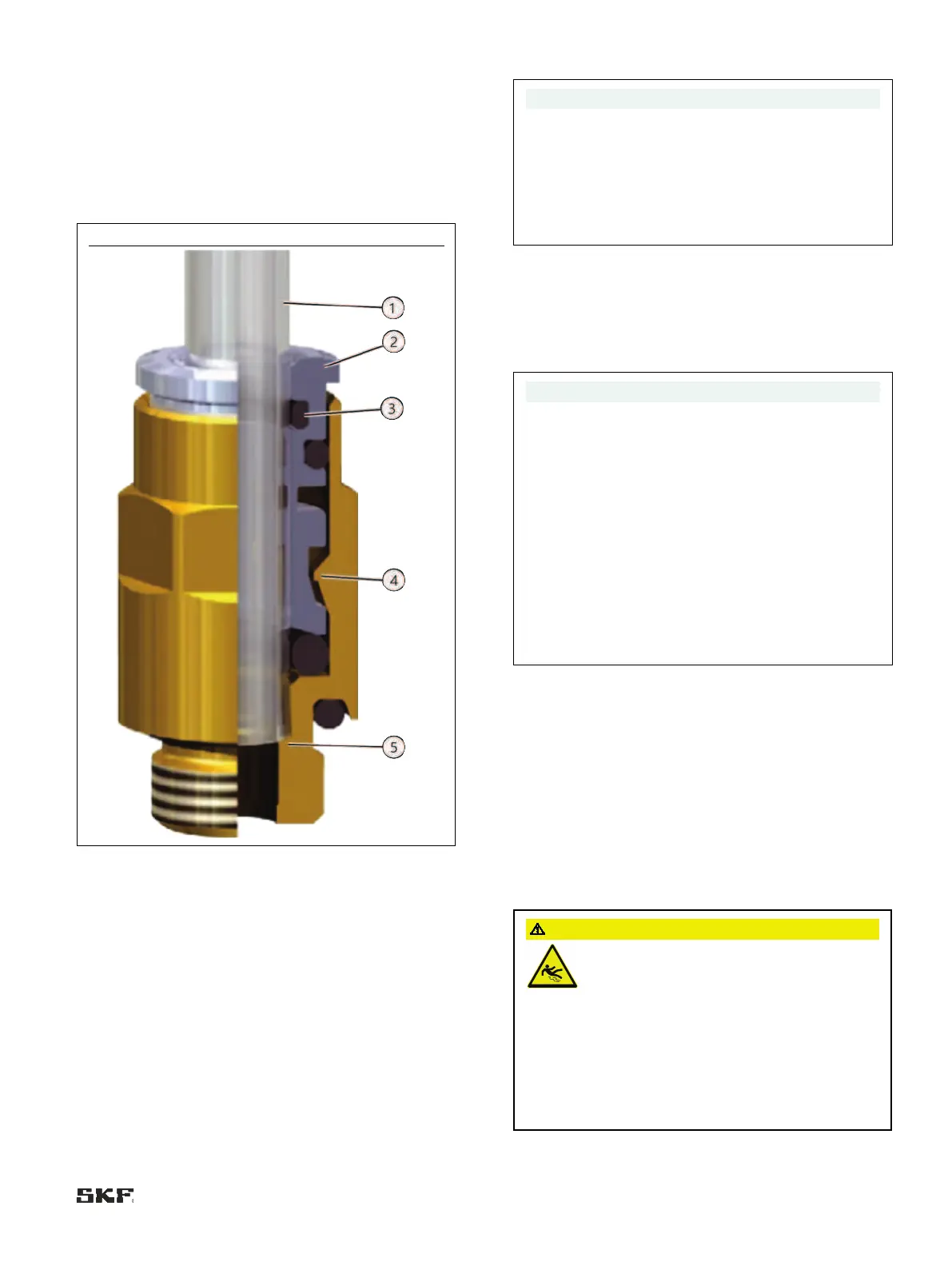

Legend to Figure 92:

1 Plastic tube

2 Collet

3 First O-ring

4 Locking claw

5 Mechanical stop

1. Cut the connecting tube (Fig. 91 or 92/1) to the correct length

with a tube cutter (see Accessories)

During the following installation of the tube, a noticeable

resistance must be overcome when passing through the

first O

-ring (Fig. 91 or 92/3) and the locking claw

91 or 92/4) of the collet (Fig. 91 or 92/2). If a claw

groove is not used, fix t

he tube using appropriate fastening

hardware (e.g., mounting clips) to prevent the tube from

slipping out of the SKF quick coupling.

2. Insert the tube (Fig. 91 or 92/1) fully into the collet

(Fig. 91 or 92/2) of the SKF quick coupling until it passes the

first O-ring (Fig. 91 or 92/3) and the locking claw

(Fig. 91 or 92/4) of the collet (Fig. 91 or 92/2) and reaches

the mechanical stop (Fig. 91/5) or (Fig. 92/6)

To remove the metal tube (Fig. 91 /1) , press the collet

(Fig.

91/2) inward into the SKF quick coupling. The metal

91/1) can now be pulled out of the collet

91/2) of the SKF quick coupling.

To remove the plastic tube

(Fig. 92 /1), press the collet

92/2) inward into the SKF quick coupling. To do this,

also press the plastic tubing (Fig.

92/1) inward into the SKF

quick coupling fitting, which releases the collet (Fig.

92/2)

from the plastic tubing (Fig.

92/1). The plastic tube

92/1) can now be pulled out of the collet (Fig. 92/2) of

Before reassembling, shorten the end of the plastic

mm to ensure that the locking claw

(Fig. 92/4) of the collet (Fig. 92/2) functions properly.

6.12 System criteria for MKL gear pump

unit

The MKL gear pump unit can be used for oil+air centralized

lubrication systems. In this case, consult the corresponding

assembly instructions for the oil+air lubrication system when

assembling and designing the system.

6.13 General information on lubrication

line routing

Risk of slipping

Personal injury or property damage due to

contaminated areas

Centralized lubrication systems must always be

free of leaks.

Leaking lubricant is hazardous due

to the risk of slipping and injury.

Beware of any lubricant leaking out during

assembly, operation, maintenance, or repair of

centralized lubrication systems.

Leaks must be

sealed off without delay.

Loading...

Loading...