57

11. Faults, causes, and

remedies

Electric shock

Performing work on products that have not

been de

-energized may result in serious

Disconnect the product from the power supply

before any work on electrical components.

Assembly, maintenance, and repair work may only

be performed on products that have been de

-

energized by qualified technical personnel. The

supply voltage must be switc

hed off before

opening any of the product's components.

Pressure

Damage and injury from working on

pressurized system components

Centralized lubrication systems are pressurized

during operation. Centralized lubrication systems

must therefore be depressurized before starting

assembly, maintenance, or repair work, or any

system modifications or system repairs.

Burn injury hazard

Injury due to hot surfaces on system

components

The hot surfaces of a motor could cause burns.

Motor surfaces may only be

touched with

appropriate gloves or after the motor has been

shut off for an extended time.

Dismantling of the product or individual parts of the product

within the statutory warranty period is prohibited and voids

any claims

Any assembly, maintenance, and repair work beyond this

scope must be performed by the Service

department of

SKF Lubrication Systems Germany GmbH only

Only original spare parts from

SKF

Lubrication Systems Germany GmbH may be used.

Unauthorized alterations to products and the use of non

-

original spare parts and accessories are prohibited.

The following tables provide an overview of possible

malfunctions and their causes. Contact the SKF Service

department if you cannot remedy the malfunction.

11.1 Prior to beginning troubleshooting

If the gear pump unit does not pump, first check the customer’s

power supply. Only after the power supply has been verified and

there are no system-related malfunctions outside of the pump

should you search for and resolve the source of the error on the

pump in accordance with Chapter 11.3 Commissioning, product,

and system malfunctions.

11.2 Replacing a defective fuse (24 VDC)

Defective fuse

Danger from using an incorrect fuse

The cause of the malfunction must be resolved prior to

replacing the defective fuse.

The defective fuse may only be replaced with a fuse of the

same type.

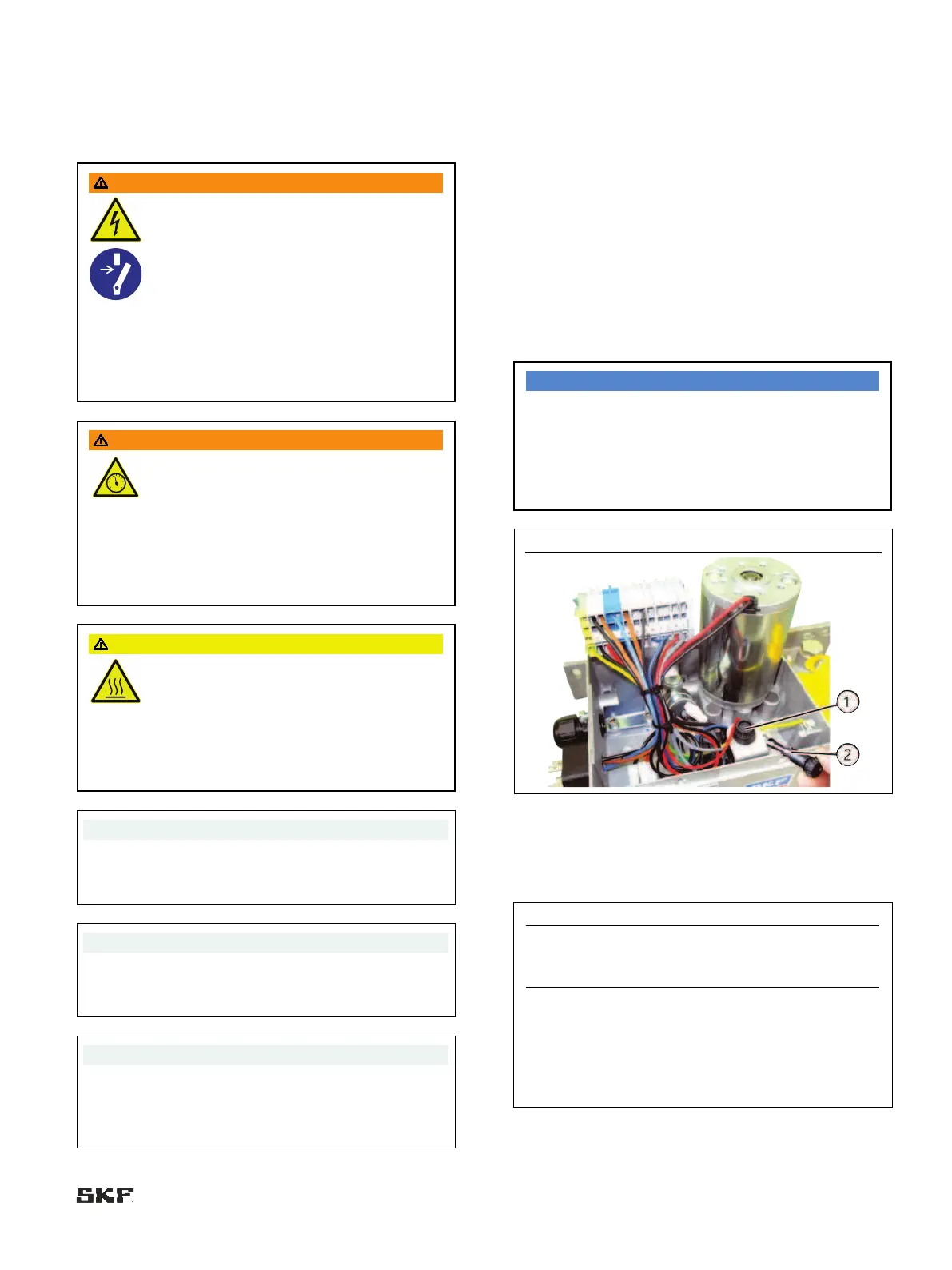

Fuse replacement

Legend to Figure 95:

1 Bayonet closure of the fuse housing

2 Defective fuse

Fuse

Cartridge fuse link (5x20 mm)

T2A per DIN

EN 60127-2

0820-

1. Resolve the cause of the malfunction

2. Disconnect the gear pump unit from the power supply

Loading...

Loading...