22

Electronic Controller

Service Manual

SKOPE Reflex Underbench Fridge and Freezer

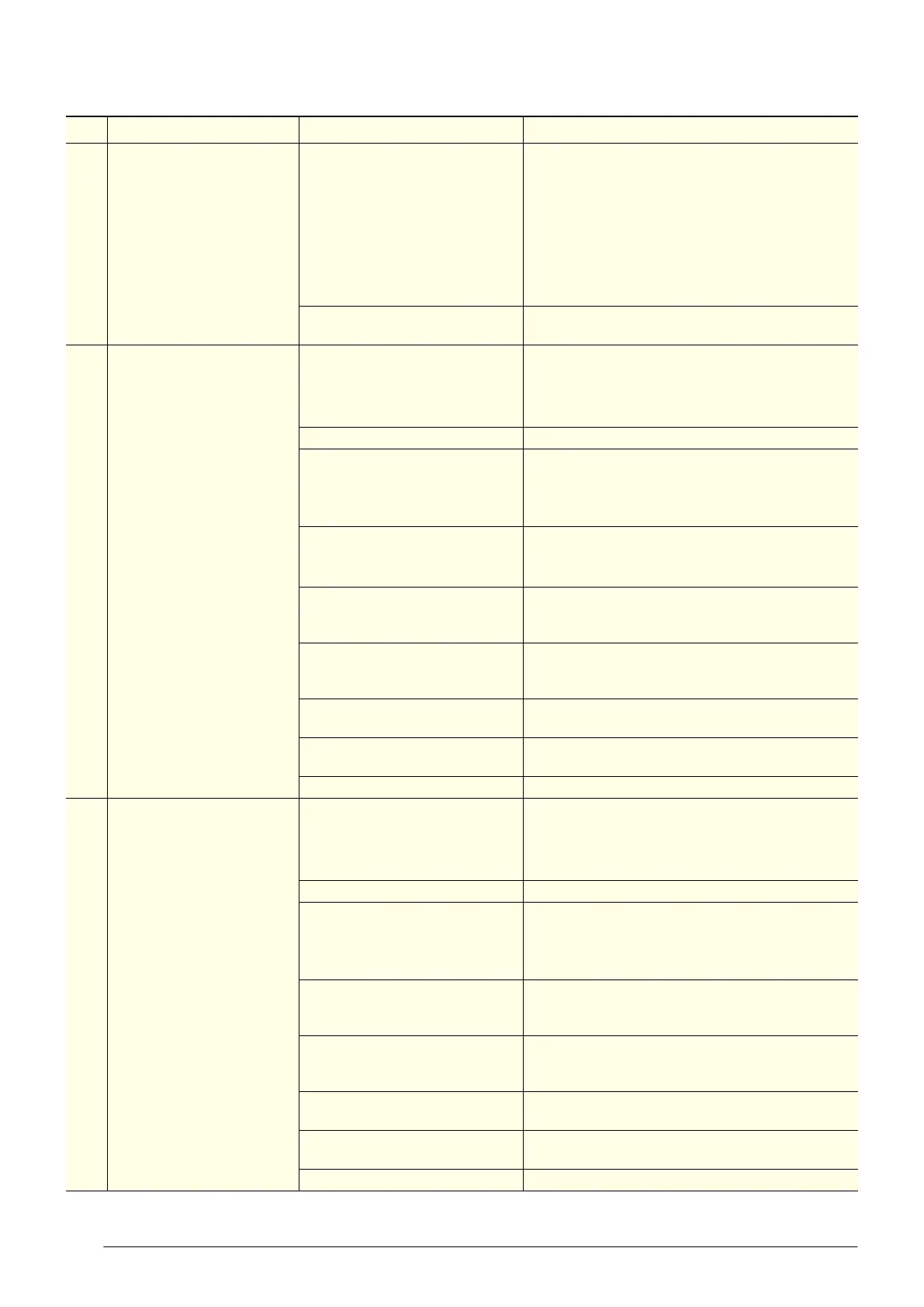

27

Probe failure

A probe other than the control

probe has failed. The cabinet

will continue to operate with

partial function but requires

service.

Cartridge swap is not required.

• Evaporator probe or

connections

• Either:

• Measure the probe resistance to make sure it

is within the range.

• Compare the probe’s temperature with the

known temperature, using an external trusted

thermometer.

• Replace the probe if required.

• Controller

• The controller may be reading incorrectly and

need replacing.

28

No downward tendency

The temperature is no longer

decreasing.

• Blocked condenser

• Remove and clean the condenser filter.

• Check that the condenser is free of debris.

• If the coil is dirty, clean it with a vacuum cleaner or

soft brush.

• Poor installation or ventilation • Check the installation guidelines.

• Cartridge or cabinet gasket

seals leaking

• Check that the gasket is intact and not broken and

leaking. If required, replace the door gasket.

• Ensure the installation levers are lifting the

cartridge up onto the case correctly.

• Door not self-closing or door

gasket leaking

• Open the door and let it go. If it does not close on

its own, repair the self-closing mechanism.

• If required, replace the door gasket.

• Product blocking cabinet airflow

• Check if the return air grille is covered by product.

If so, move the product from the grille and

observe.

• Compressor is overloaded from

excess door openings or

ambient temperature

• Ensure that the cabinet is operating in its climate

class.

• Condenser or evaporator fan

motor or blade

• Inspect the condenser and evaporator fans safely,

and replace if faulty.

• Controller

• The controller may be reading incorrectly and

need replacing.

• Compressor or gas leak • Swap the cartridge.

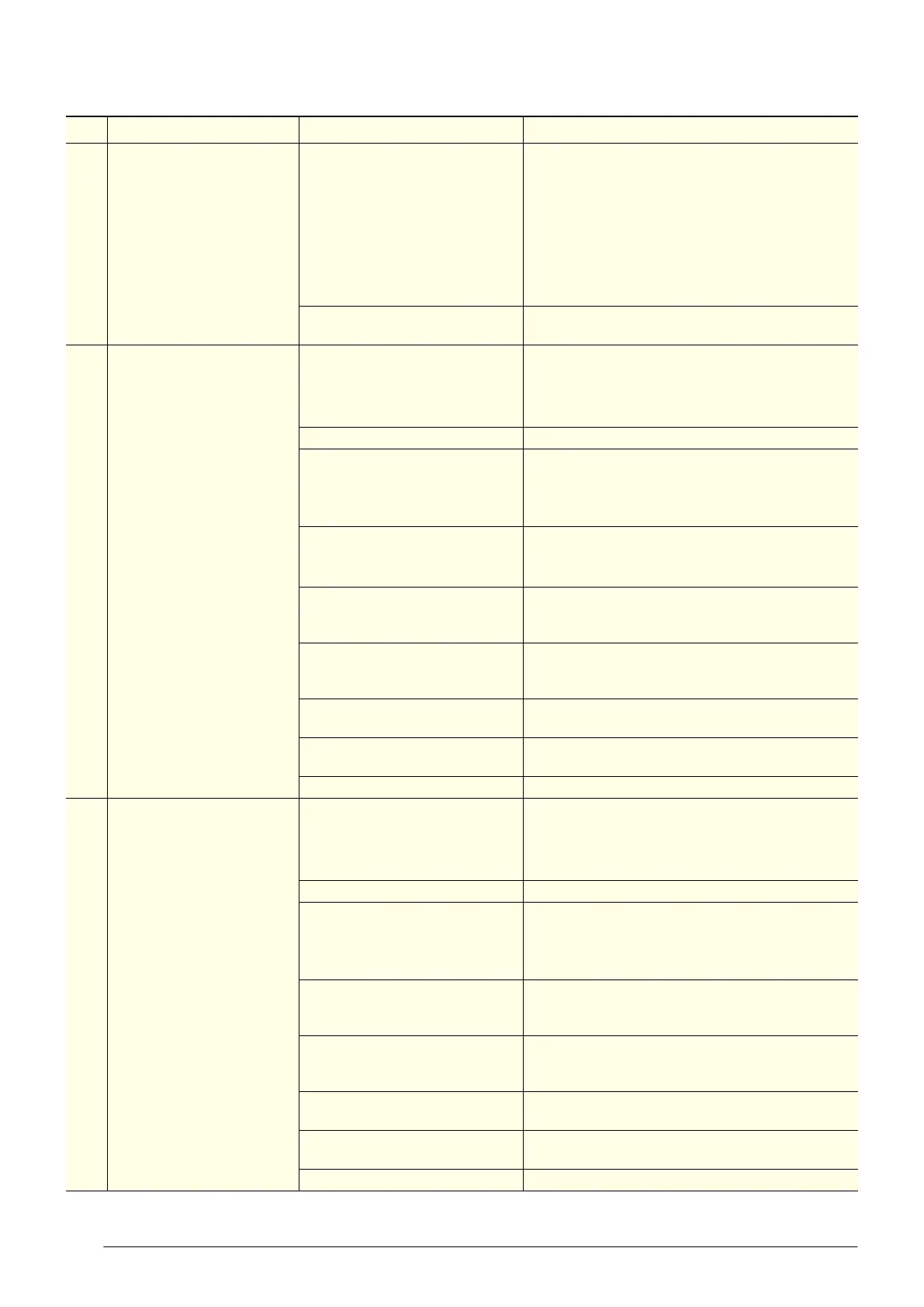

29

Compressor cutting out

The compressor cut out on its

internal protection or pressure

switch.

• Blocked condenser

• Remove and clean the condenser filter.

• Check that the condenser is free of debris.

• If the coil is dirty, clean it with a vacuum cleaner or

soft brush

• Poor installation or ventilation • Check the installation guidelines.

• Cabinet, door, or cartridge

gasket leaking

• Check that the gasket is intact and not broken and

leaking. If required, replace the door gasket.

• Ensure the installation levers are lifting the

cartridge up onto the case correctly.

• Product blocking cabinet airflow

• Check if the return air grille is covered by product.

If so, move the product from the grille and

observe.

• Compressor is overloaded from

excess door openings or

ambient temperature

• Ensure that the cabinet is operating in its climate

class.

• Condenser or evaporator fan

motor or blade

• Inspect the condenser and evaporator fans safely,

and replace if faulty.

• Controller

• The controller may be reading incorrectly and

need replacing.

• Compressor or gas leak • Swap the cartridge.

Table 6: Alarms (continued)

Code Description Possible root cause Action

Loading...

Loading...