31

SKOPE Reflex Underbench Fridge and Freezer

Replacement Procedures

Service Manual

Removing the

Cartridge

Note: The electronic controller and electrics panel (including light power supply) is matched to

the cabinet, and must be left with the cabinet when exchanging the cartridge. Replacement

spare part cartridges are not supplied with controller and electrics panel.

Follow the steps below and image over the page to remove the refrigeration cartridge from the

cabinet. Ensure the cabinet is disconnected from the power supply before removing the

cartridge.

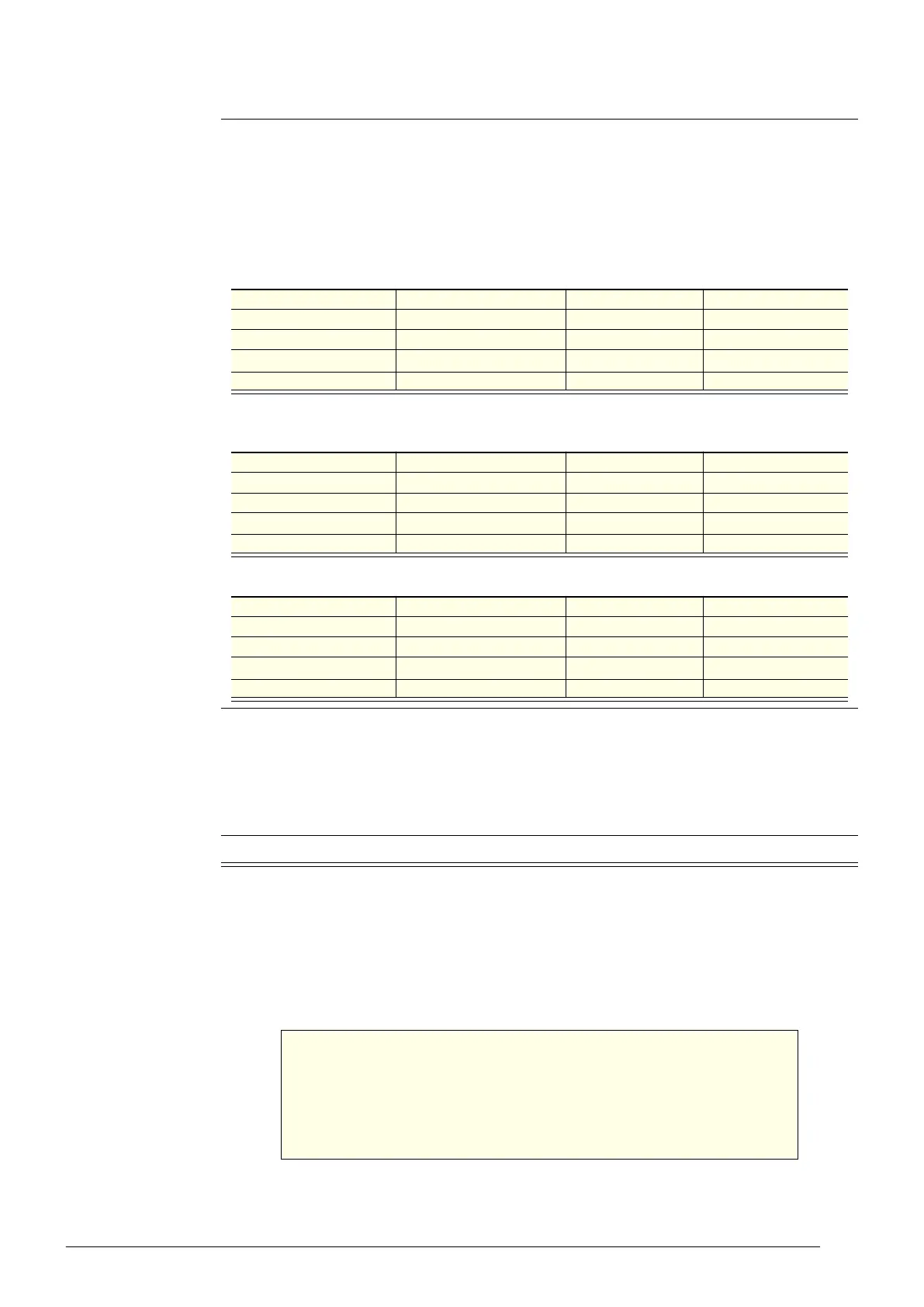

8. Use the relevant table below as a guideline to determine if the system charge is correct at typical

ambient conditions around 25°C for a cartridge running on the bench.

The point where the frost

stops is affected by the ambient temperature.

• Generally, a system with the correct refrigerant charge will frost back to the compressor.

• If the frost does not go back to the point shown there may be a capillary blockage or

compressor fault.

9. Determine whether the system is short of refrigerant, blocked capillary or compressor fault.

A dry suction could indicate either short of gas, blocked capillary or compressor fault, and further

analysis may be required.

• If there is no frost present at the evaporator coil inlet pipe a blocked capillary is likely.

• If frost is forming at evaporator coil inlet pipe system, and suction/compressor is behaving as

shown in the relevant table above at 50% or 75%, the system is likely to be short of gas.

10. After fault has been diagnosed and repaired, reassemble the refrigeration system and test run.

Procedure 14: To diagnose lack of gas (continued)

Table 7: RF7.UBR.2.SD, RF7.UBR.2XL.SD, RF7.UBR.2.GD

(cartridge ULKCNI-0021, ULKCNI-0027, ULKCNI-0040-P)

Observation 50% charged 75% charged 100% charged

Suction pipe at compressor Suction dry Suction dry Suction cold

Evaporator coil Top row return bends frosted ½ return bends frosted All return bends frosted

Cartridge power

Less than 100 W 110 W to 115 W Greater than120 W

Evaporator temperature Greater than -10°C -10°C to -12°C Less than -15°C

Table 8: RF7.UBR.3.GD, RF7.UBR.3.SD, RF7.UBR.4.GD, RF7.UBR.4.SD

(cartridge ULKCNI-0022, ULKCNI-0028, ULKCNI-0041-P)

Observation 50% charged 75% charged 100% charged

Suction pipe at compressor Suction dry Suction dry Suction cold

Evaporator coil No return bends frosted ½ return bends frosted All return bends frosted

Cartridge power

Less than 13 5W 135 W to 145 W Greater than 145 W

Evaporator temperature Greater than -10°C -10°C to -12°C Less than -15°C

Table 9: RF7.UBF.2.SD, RF7.UBF.3.SD (cartridge ULKCNI-0023)

Observation 50% charged 75% charged 100% charged

Suction pipe at compressor Suction dry Suction cold Suction cold and wet

Evaporator coil Top row return bends frosted ½ return bends frosted All return bends frosted

Cartridge power

Less than 27 5W 290 W to 300 W Greater than 300 W

Evaporator temperature Greater than -15°C Less than -30°C Less than -30°C

WARNING

The cabinet body is connected to installation earth via the

refrigeration cartridge. Removing the cartridge removes the

cabinet earth. NEVER connect cabinet heating leads to the

electrics box or any other power supply with the cartridge

removed or risk of electric shock may be created.

Loading...

Loading...