6.4 Preparation

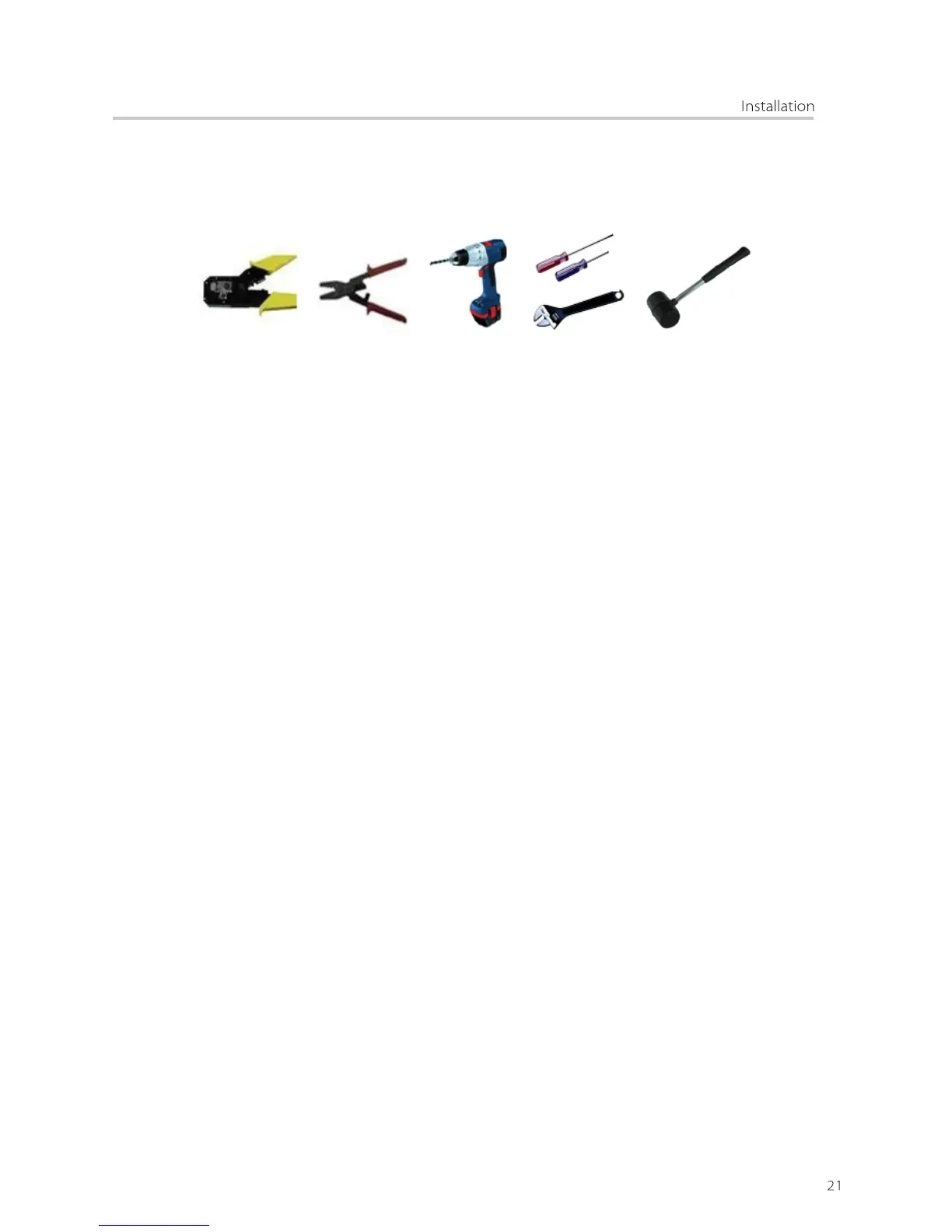

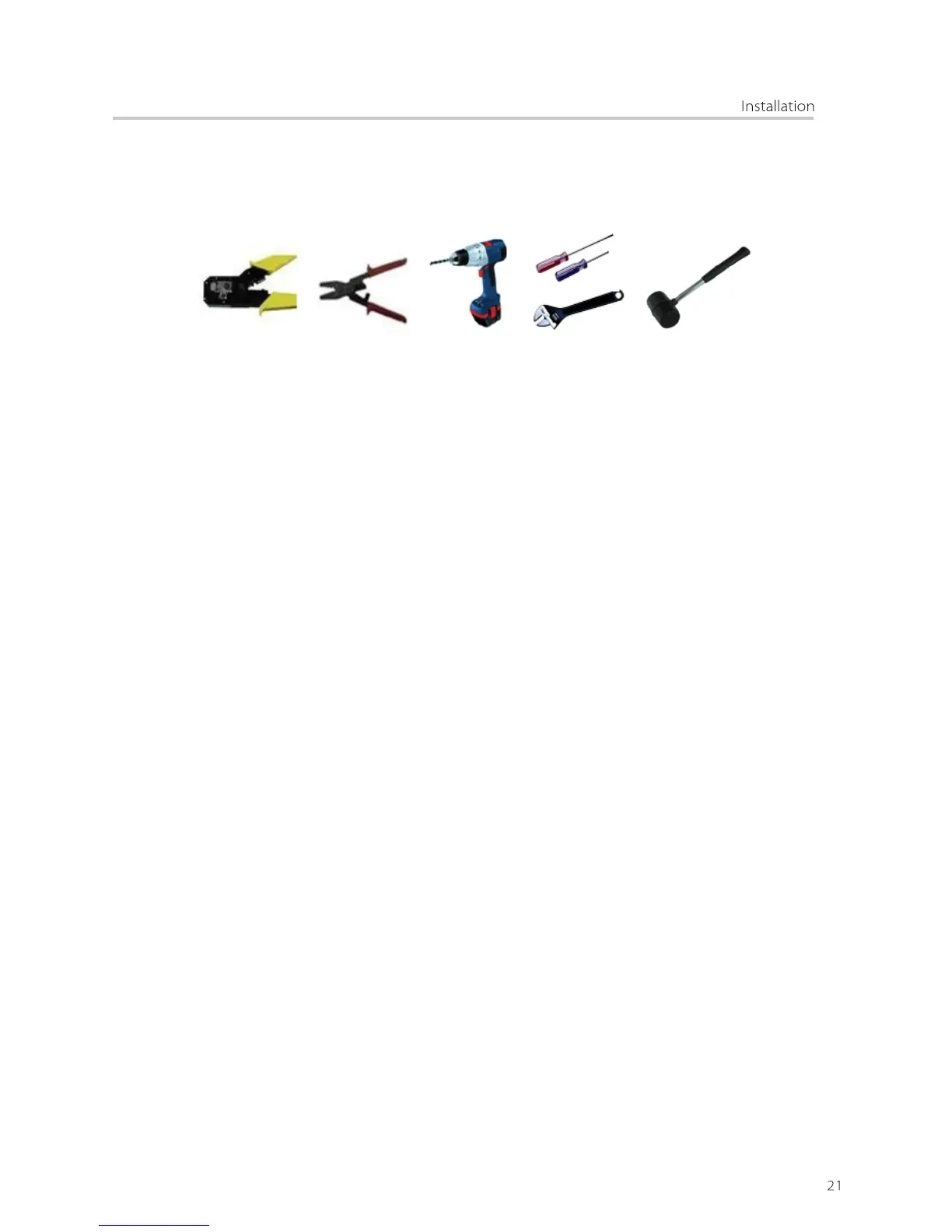

Below tools are needed before installation.

Installation Tools

Installation Tools: crimping pliers for binding post and RJ45, screwdriver, manual

wrench, ф 6 driller and rubber hammer.

The unit is heavy. Do not lift it alone.

Lifting and Handling

• During lifting procedures ensure that the unit is firmly secured to avoid the risk

of accidental tipping or dropping.

• Parts serving for support or immobilization of unit shall be designed and

manufactured so as to minimize the risk of physical injuries and of accidental

loosening of fixing.

• Ensure that the method of lifting will not allow the unit to slip from chains and

slings or turn-over or slide from lifting devices.

• Transportation must be carried by specialized person (truck operators. Hook-up

personal), equipped with the necessary protection equipments (overalls, safety

shoes, protective gloves, helmets, goggles)

• Do not walk or stand beneath or in the proximity of the load.

• Avoid sudden movements and jolts when unloading and positioning the unit.

Internal handling procedures must be conducted with care. Do not exert

leverage on the components of the machine.

• If the unit is not balanced apply ballast. Any protruding parts should not be

supported by hand.

• The inverter should be installed so that the operating panel shall be easily

accessible- easy access to the electrical power connection point.

• Accessible for maintenance and repair work.

• Parts serving for support or immobilization of unit shall be designed and

manufactured so as to minimize the risk of physical injuries and accidental

loosening of fixings.

• Loading capacity and hardness of the supporting surface, load rating of

mounting bracket should be at least four times the weight of the devices

according to IEC62109-1. and supporting characteristics will be impaired by

wear, corrosion, material fatigue or ageing, This should be calculated by

inspection of the design data of supporting material and consulting

construction engineer.

Loading...

Loading...