54 • Installation

_____________________________________________________________________________________________

6. INSTALLATION

Do not interchange line and load connections

When mains voltage is connected to the RVS-DN, even if control voltage is

disconnected, full voltage may appear on the RVS-DN’s load terminals.

Therefore if isolation is required you must connect an isolation device between

the mains and the RVS-DN.

WARNINGS!

Power factor correction capacitors must not be installed on the load side of the

RVS-DN. When required, install capacitors on the line side of the RVS-DN.

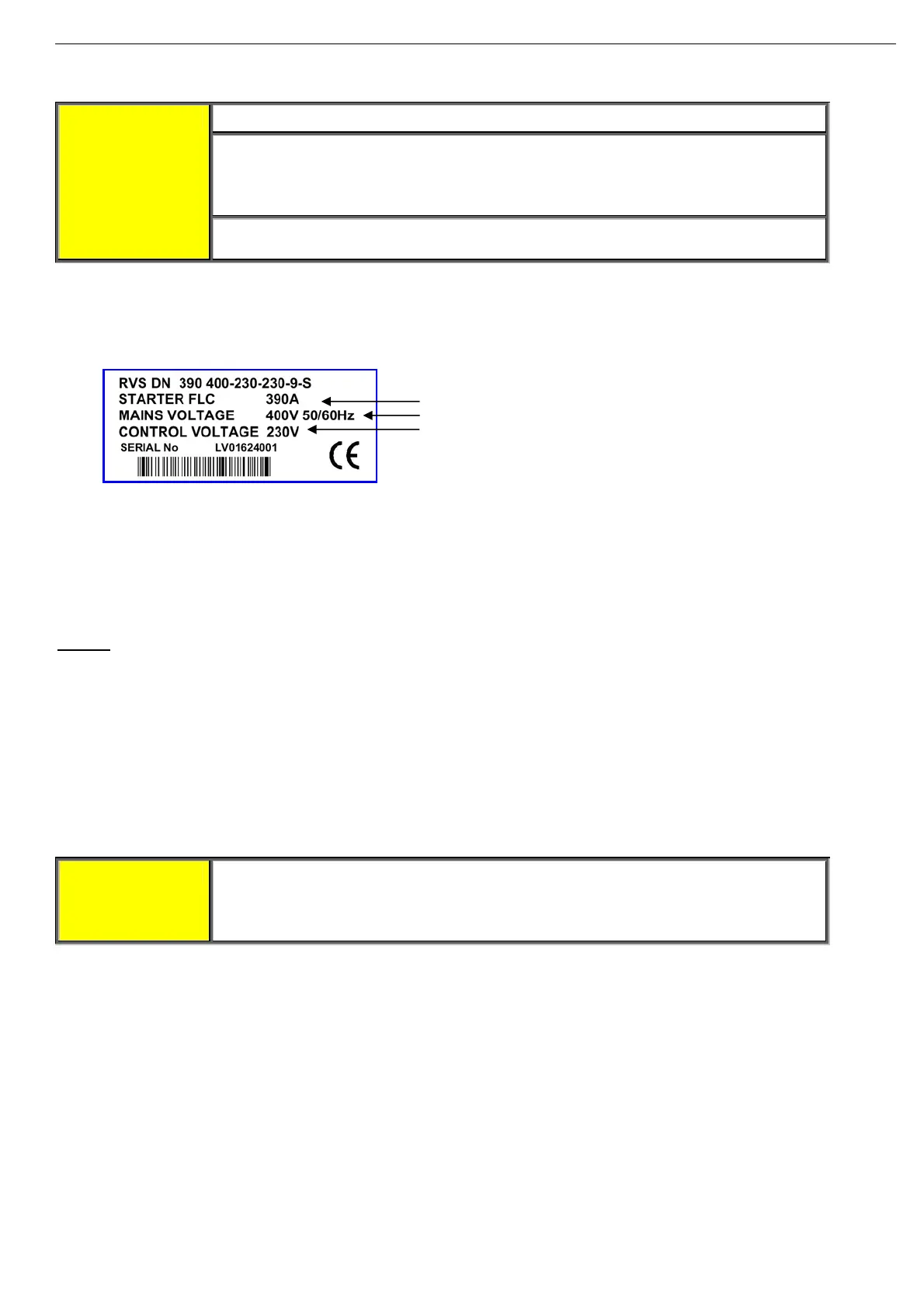

6.1 Prior to Installation

Check that t

he Full Load Ampere (FLA) of the motor is lower than or equal to the Full Load Current (FLC) the

RVS-DN, and that the mains and control voltages are as indicated on the side and/or front label of the RVS-

DN.

Make sure RVS-DN FLC ≥ motor FLA!

Make sure mains voltage is correct!

Make sure control voltage is correct!

RVS-DN label - example

6.2 Mounting

The RVS-DN must be mounted vertically. Allow

sufficient space for suitable airflow above and below the RVS-

DN. To improve heat dissipation, it is recommended that you mount the RVS-DN directly on the rear metal

plate.

Notes:

(1) Do not mount the RVS-DN near heat sources.

(2) Surrounding air temperature in the cabinet should not exceed 50°C

(3) Protect the RVS-DN from dust and corrosive atmospheres.

(4) For harsh environments (sewage treatment plants, etc.) you should order the RVS-DN with the optional

harsh environment treatment (refer to ordering information page 18).

6.3 Temperature Range & Heat Dissipation

The RVS-DN is rated to

operate within a temperature range of -10°C (14°F) to + 50°C (122°F).

Relative non-condensed humidity inside the enclosure must not exceed 95%.

ATTENTION!

Operating the RVS-DN with a surrounding air temperature that is higher than

50ºC will cause derating.

Operating the RVS-DN with a surrounding air temperature that is higher than

60ºC may cause damage to the RVS-DN.

Heat dissipation from the RVS-DN is calculated as:

Ploss=3x1.3xI+FAN loss

where:

I represents motor current. Note that the motor current during the start process is higher than the motor rated

current.

FAN loss represents power loss caused by all internal fans (refer to section

10 page 99 for fan loss per

model).

For example

, during start of a 820A motor when CURRENT LIMIT is set to 400%, heat dissipation can be

calculated as:

Ploss=3x1.3x4x820+150=12,792Watt≈12.8kW

While a 820A motor is running and the motor current is 820A, heat dissipation can be calculated as:

Ploss=3x1.3x820+150=3,198Watt≈3.2kW

Loading...

Loading...