ST500 Tach-Timer Installation

© Stack Limited

19

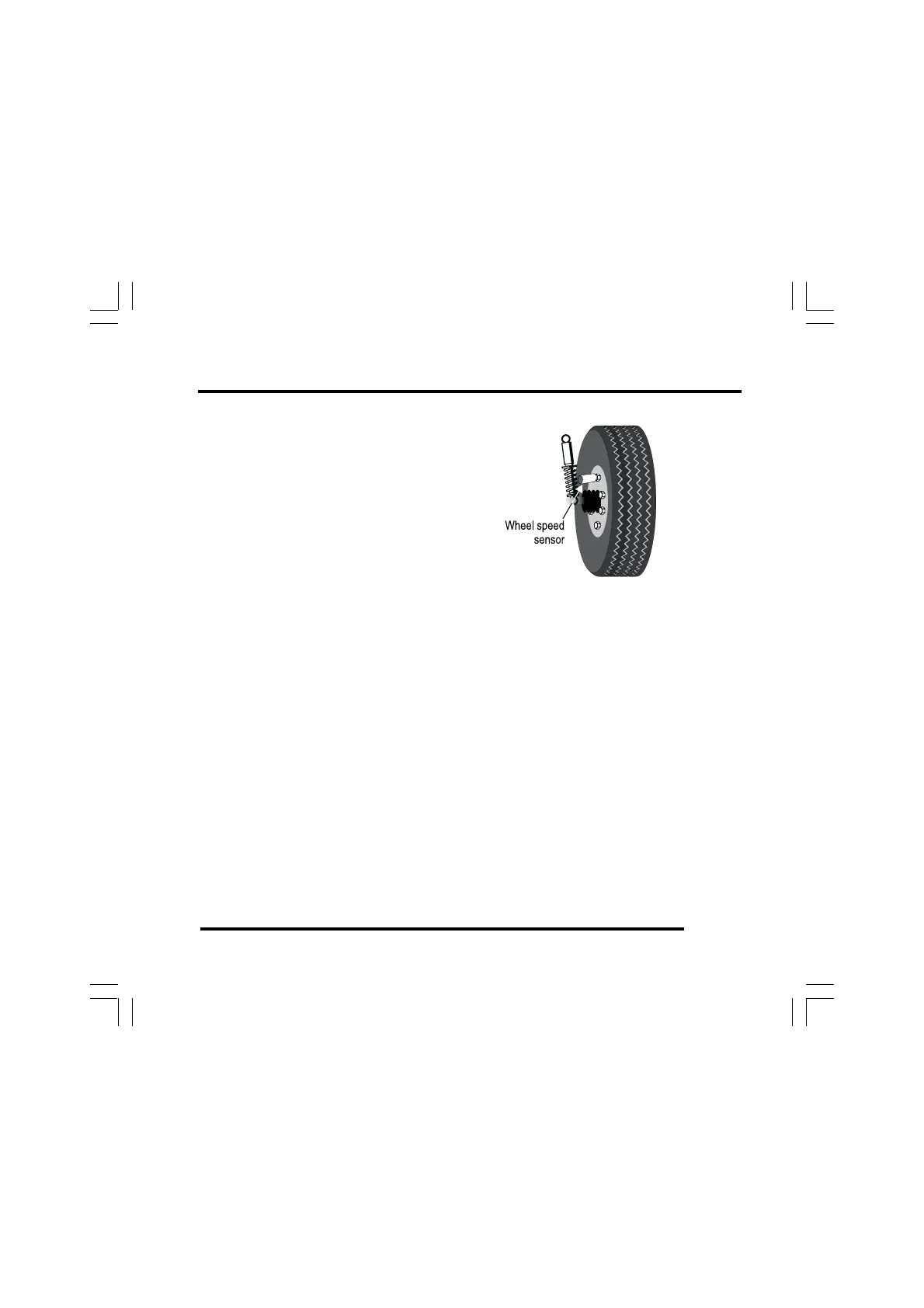

not try to use these as targets.

• If possible, choose a wheel that ex-

periences negligible wheel spin, lift

or lock-up – for example, an

undriven wheel.

• Ideally, the targets should be

equally spaced around the wheel

so that, with a constant wheel

speed, the electrical pulses occur at

regular intervals.

• To avoid excessive heating do not install the sensor too close to

the brake disc.

• Position the sensor no closer than 75 mm (3 inches) to ignition

HT leads or sources of intense heat.

2 Make a suitable rigid bracket to support the sensor and attach it to

the vehicle. Fit the sensor to the bracket. Do not over tighten the

sensor.

3 Adjust the clearance between the end of the sensor and the ferrous

targets so that the gap is nominally 1.0 mm ± 0.5 mm (0.040 ±0.020

inches). Make certain there are no other objects passing within 4 mm

(X-inch) of the sensor when the wheel rotates.

4 Attach the wire labelled ‘WS’ of the harness to the sensor at the 4-

Figure 9 - Wheel speed sensor

Loading...

Loading...