TUP500 Series Product Specifications

8-13

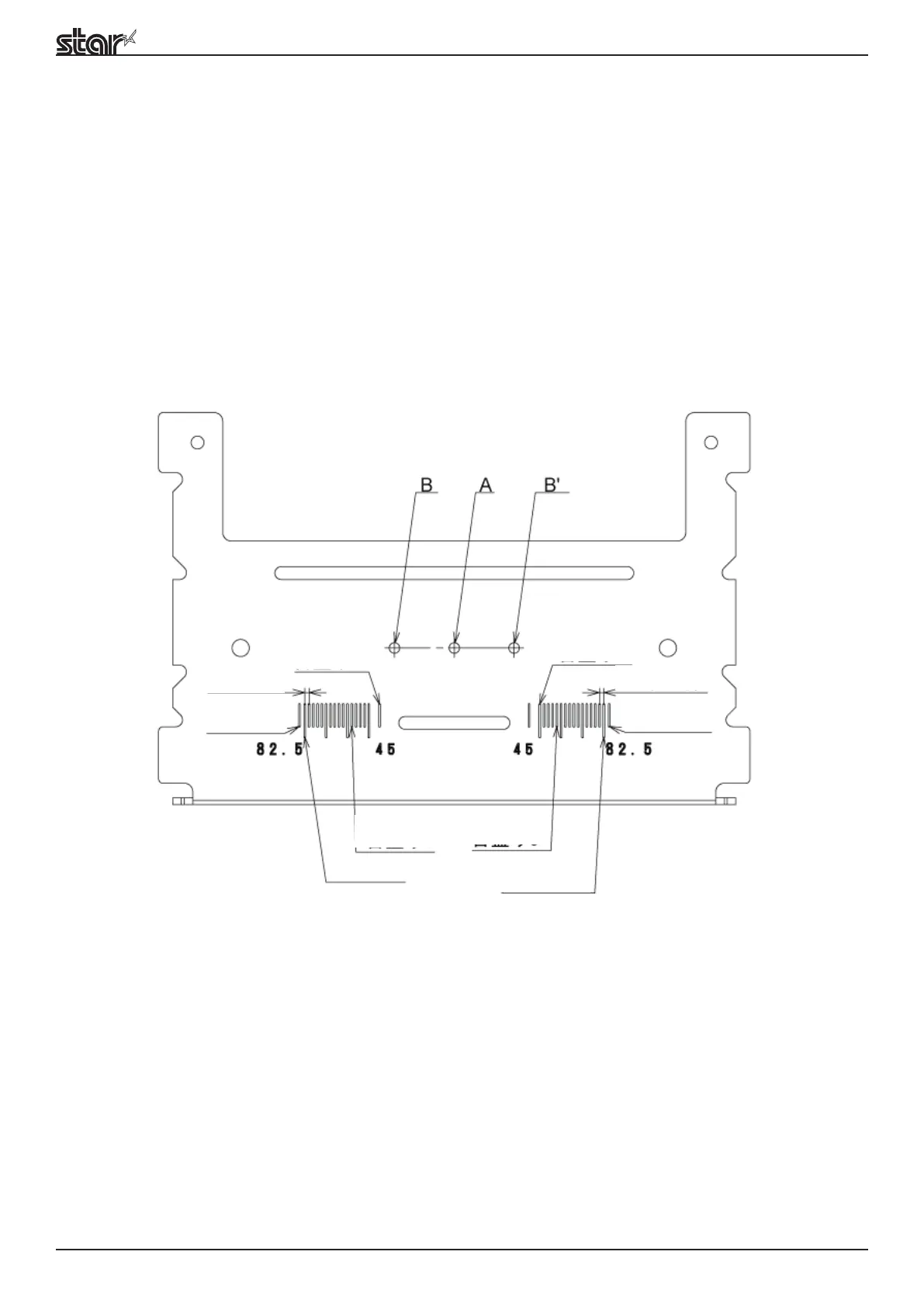

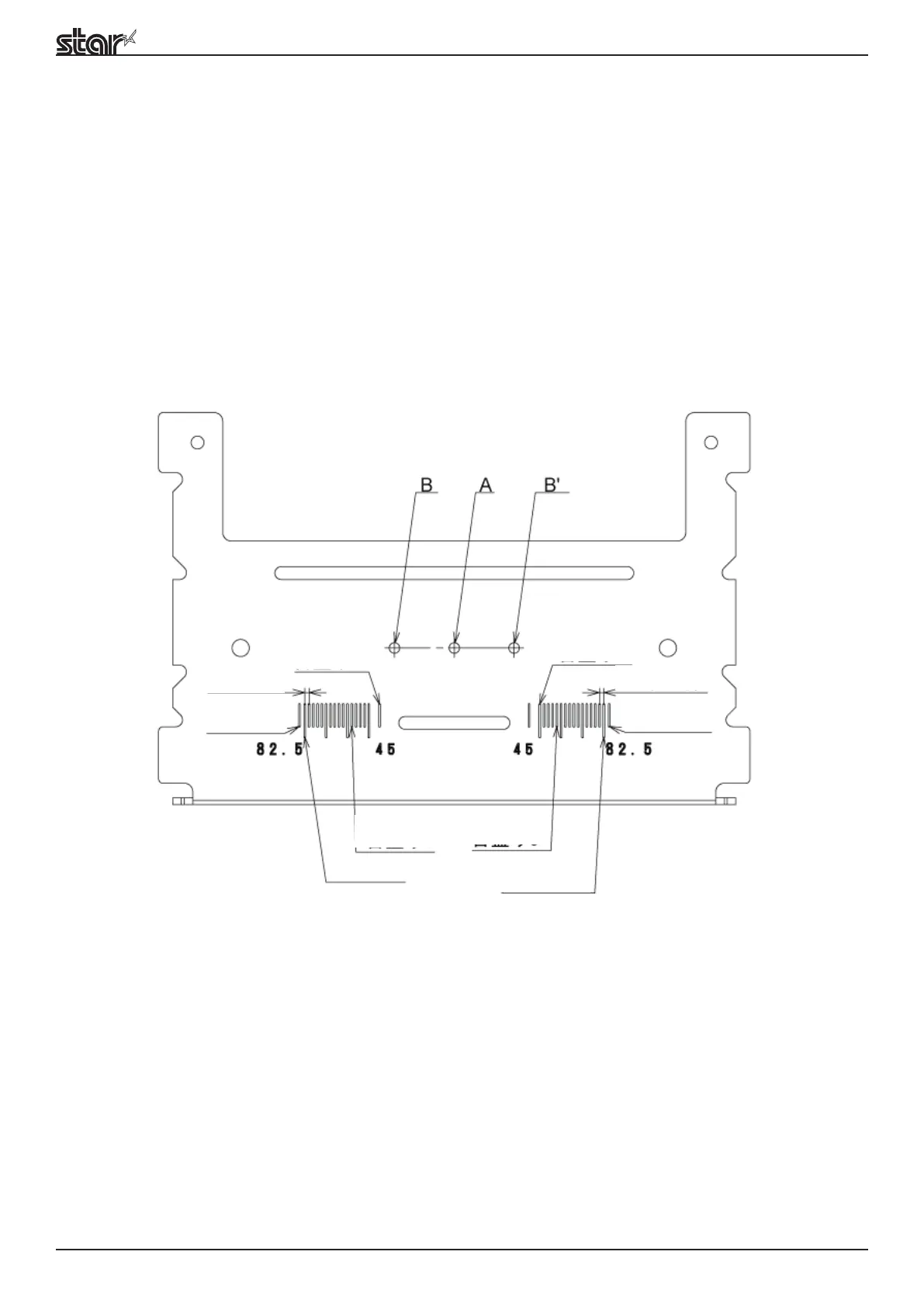

8.3. Fastening the Friction Spring

It is necessary to adjust the friction spring position for the width of the paper you intend to use. If the setting posi-

tion is incorrect, the roll paper will be supplied improperly to the mechanism which in turn causes paper transport

problems. Thus, it is should be properly adjusted.

Notes:

1. After adjusting the position, slowly turn the roll paper to check that it turns smoothly.

2. It is necessary to make fine adjustments to the friction spring position according to the

roll paper material.

Contact us for details on fine adjustments.

8.3.1. Using the Spring Base

The scale of the spring holder shown in Fig. 8.3.1.A. is a 2 mm pitch. Adjust or mount the friction spring width of

the paper you intend to use. The following shows the representative paper width settings.

Notes:

1. Fit the friction spring between the top and bottom guide rail on the spring base to fasten

the friction spring. At this time, be careful that the friction spring is not riding up on the

guide rail when fastened.

Fig. 8.3.1.A

Scale d

Scale d

Scale c’

Scale b’

Scale c

Scale b

Scale a

Scale a

1 (Pitch)

1 (Pitch)

Loading...

Loading...