Reset

“use 0 point switch” in “Machine” and reset direction in “System” is not 0, press Reset, the axis fast moves

along reset direction, and stops when meet mechanical 0 point signal, current coordinate is parameter origin

coordinate, machine coordinate clears.

“do not use 0 point switch” in “Machine” and reset direction in “System” is not 0, press Reset, the axis fast

moves along reset direction to the machine 0 point, the current coordinate is parameter origin coordinate.

“do not use 0 point switch” in “Machine” and reset direction in “System” is 0, press Reset, the axis doesn’t

move, machine coordinate clears, current coordinate is parameter origin coordinate.

Controller supports 2 machine fixed points, and they can be switched, when cut a part, another part can be

loaded at the same time to improve efficiency.

Note:

1. When do not use 0 point switch, and continue off-line to move torch, the machine coordinate will

accumulate, clear by reset.

2. Two axis reset at the same time, one axis meets 0 point switch, two axis stop, after one axis reset, another

axis continue.

3. Fixed point coordinate is machine coordinate, when machine 0 point position changes, fixed point position

moves as well.

4. Speed to fixed point is manual speed.

Align parts (plate calibration)

If plate doesn’t align with machine axis, then manually align parts.

F1 Manual

Press direction buttons to move torch, align one side of plate, press F4 set start point.

Press direction buttons to move torch, align another point of the same side of plate, press F5 set end point.

Controller tips rotation angle, after confirm, back to Auto, preview, display the figure after rotation.

Note: after set end point, can press F6, back to the start point.

Outline

If want to check whether the plate is big enough for parts, can choose outline before cutting.

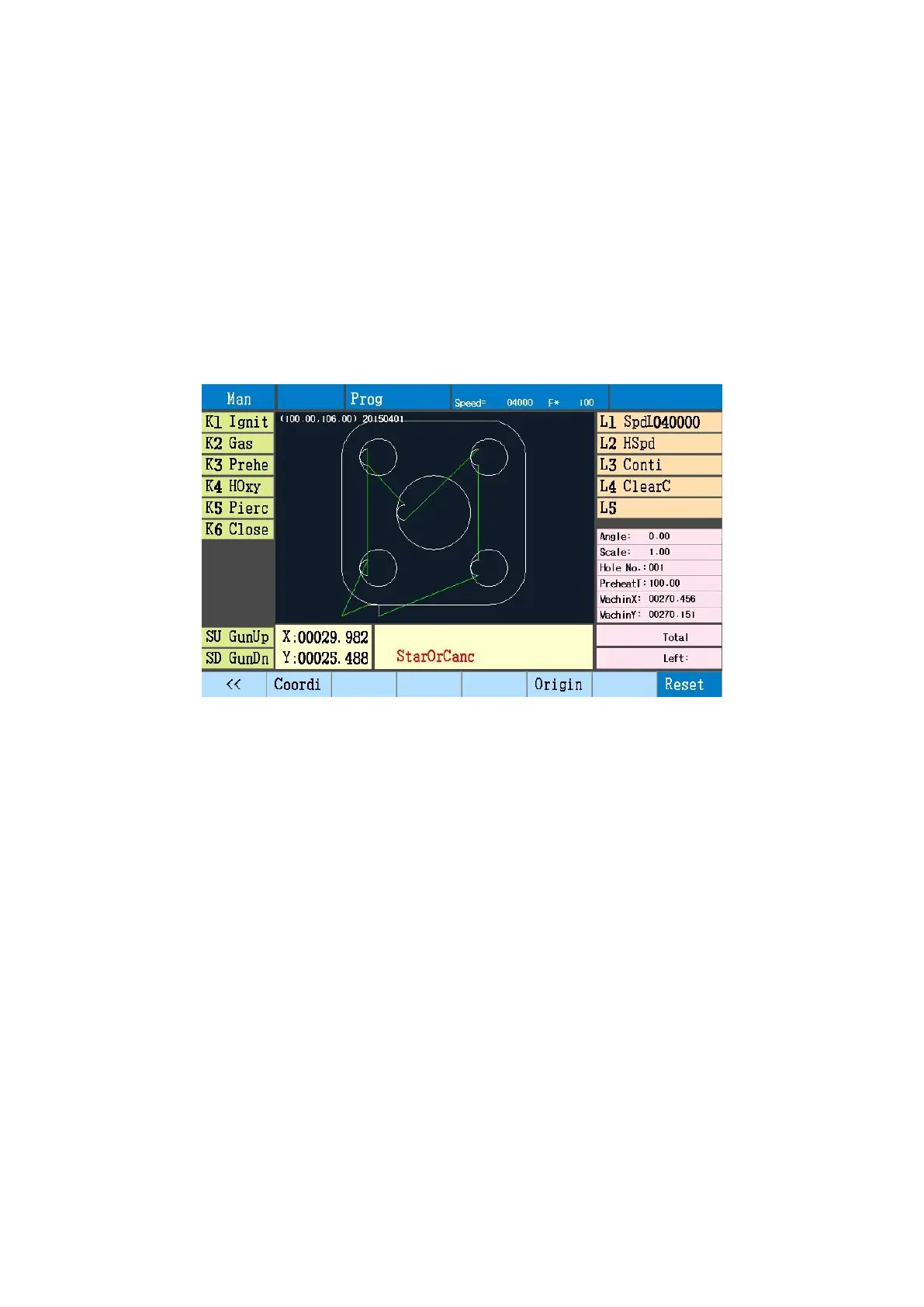

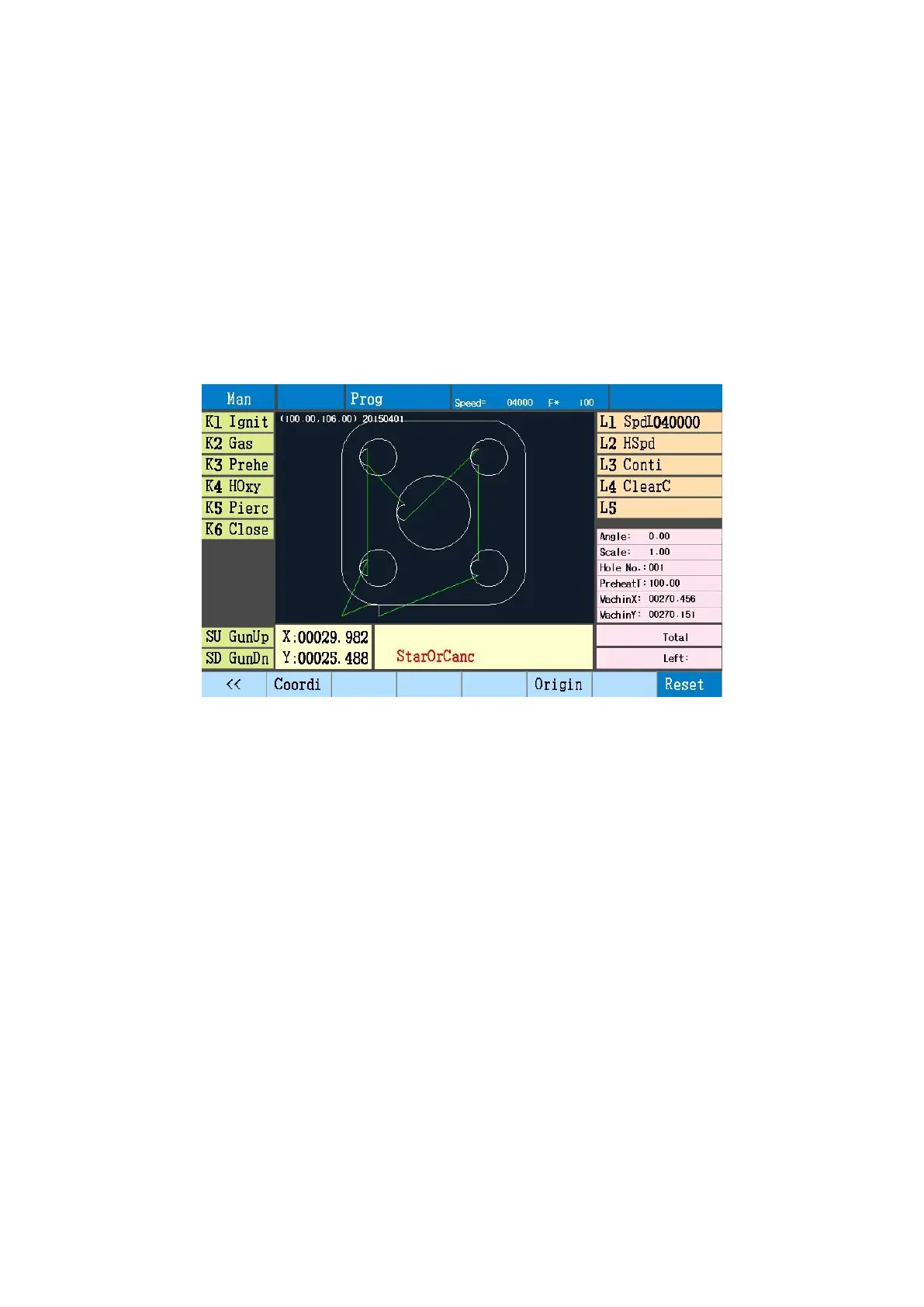

Loading...

Loading...