Note: machine origin can set to any point of value range.

Control

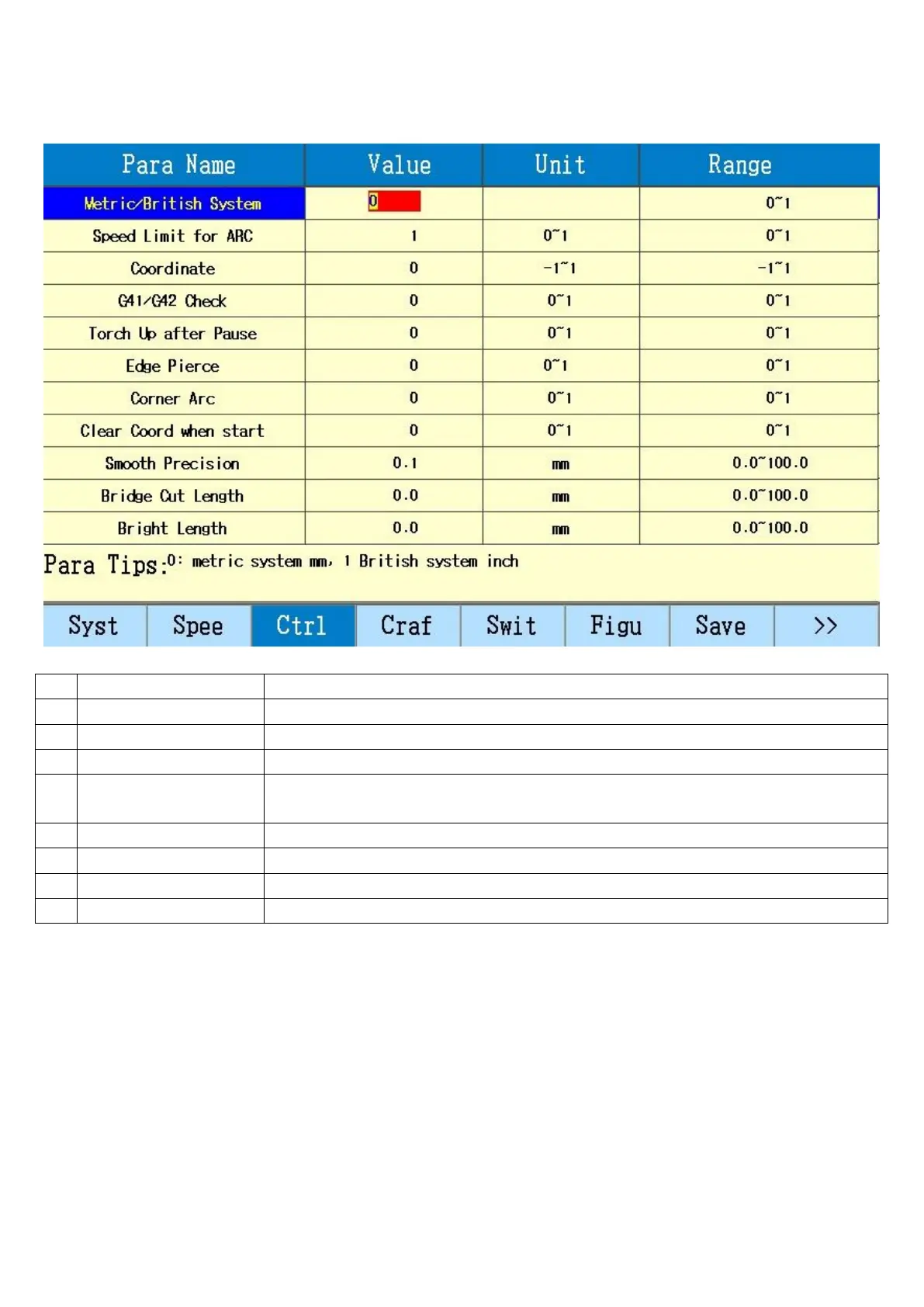

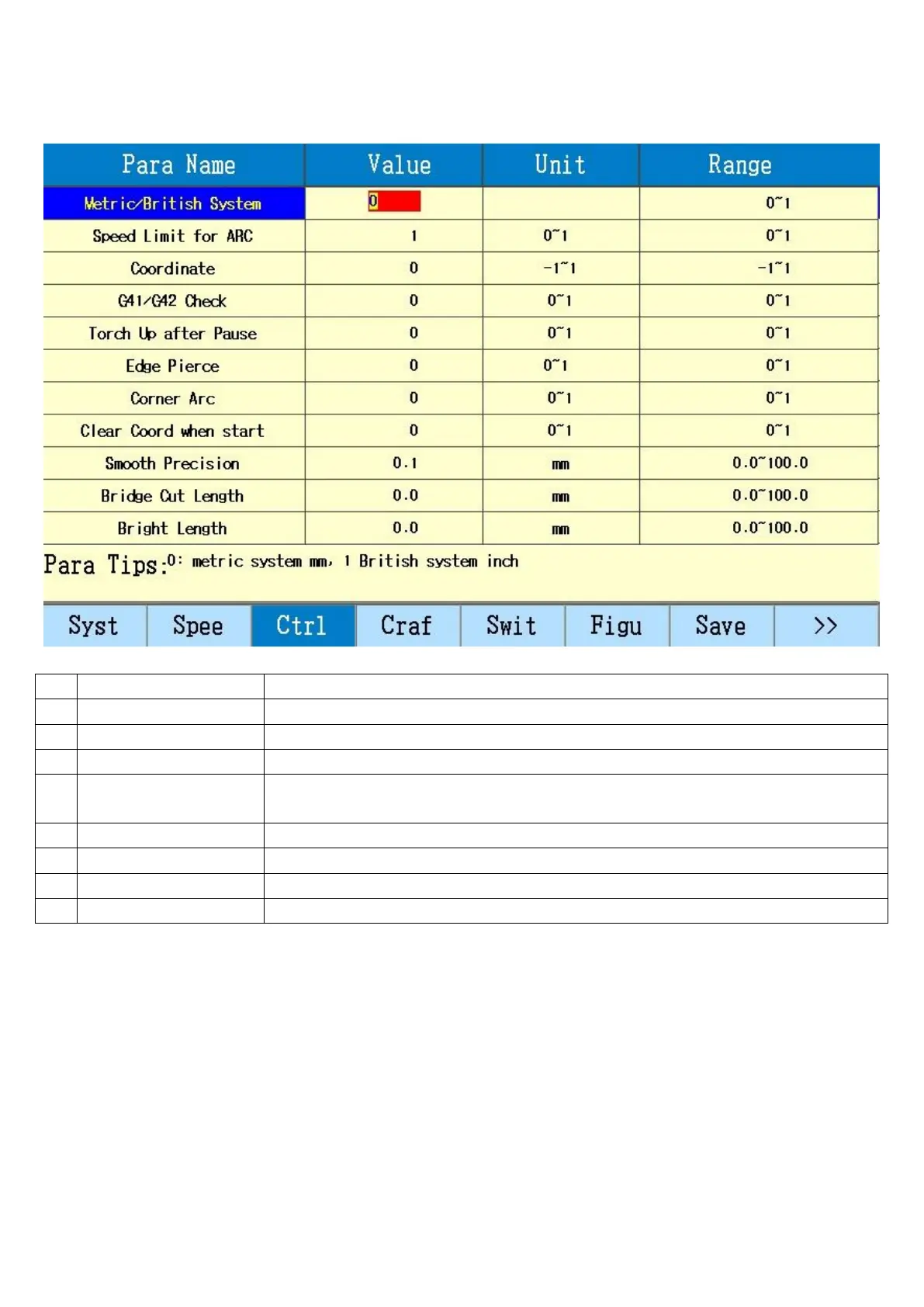

Length unit, 0: metric system (mm), 1: metric system (in)

Same as machine direction

Whether check interference caused by kerf compensation

Whether torch automatically move up after pause (height is up to torch up time)

Valid: move to pierce point, automatically pause, manually move to proper

position, after start, cut to pierce point and continue, better for thick plate.

Arc transition at corner, transition radius is kerf width

For programs with small sections, to improve stability

Set bridge, cutting length

Set bridge, bridge length

Torch Up after Pause: Choose 1, press “torch up delay” after pause, torch moves up after the time, after start

again, press “torch down delay”, torch moves down after the time, choose 0, after pause, torch keeps the

current cutting height.

Edge Pierce: Valid: torch moves the pierce point, options column appear, choose “edge pierce”, “continue

locally”, “no pierce”.

F5 Edge Pierce, this moment can manually move torch, away from original path, choose plate edge pierce,

then cut back to the previous point in shortest path, continue the left cutting, equal to cutting return after

pause, can reduce preheat time for thick plate and improve cutting efficiency.

F6 Local Pierce, pierce at local point and continue left cutting.

F7 No Pierce, idle run the path till next pierce point, new tip appears.

Note: when several pierce points, there is tip for every pierce point.

Smooth Precision: When use parts drawings not made by CAD, such as art word, with lots of small sections,

use smoothness precision to improve cutting efficiency.

Loading...

Loading...