Preheat time, default is 100s for new program

Pierce time at pierce height

Keep output when pierce and XY axis start to move

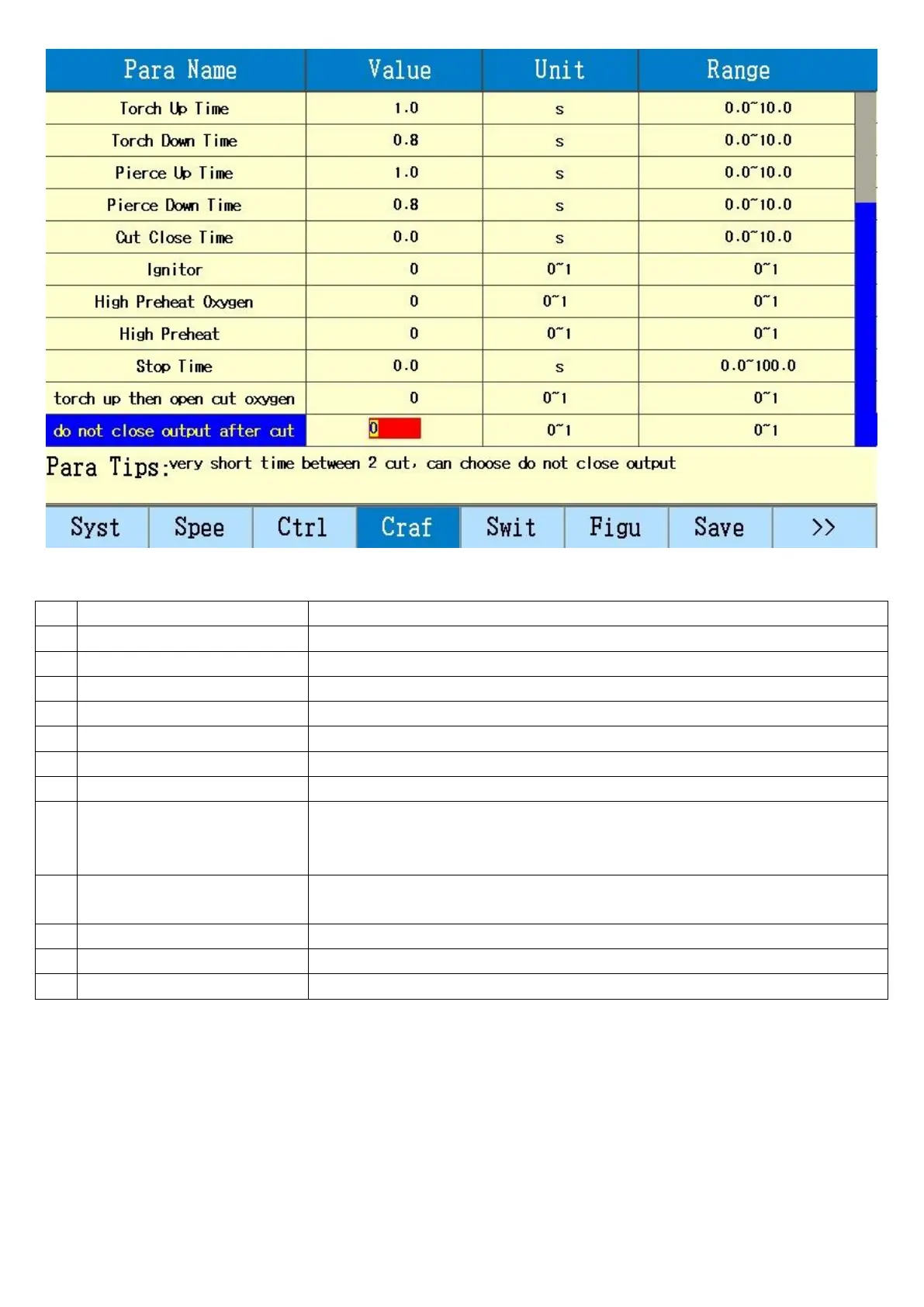

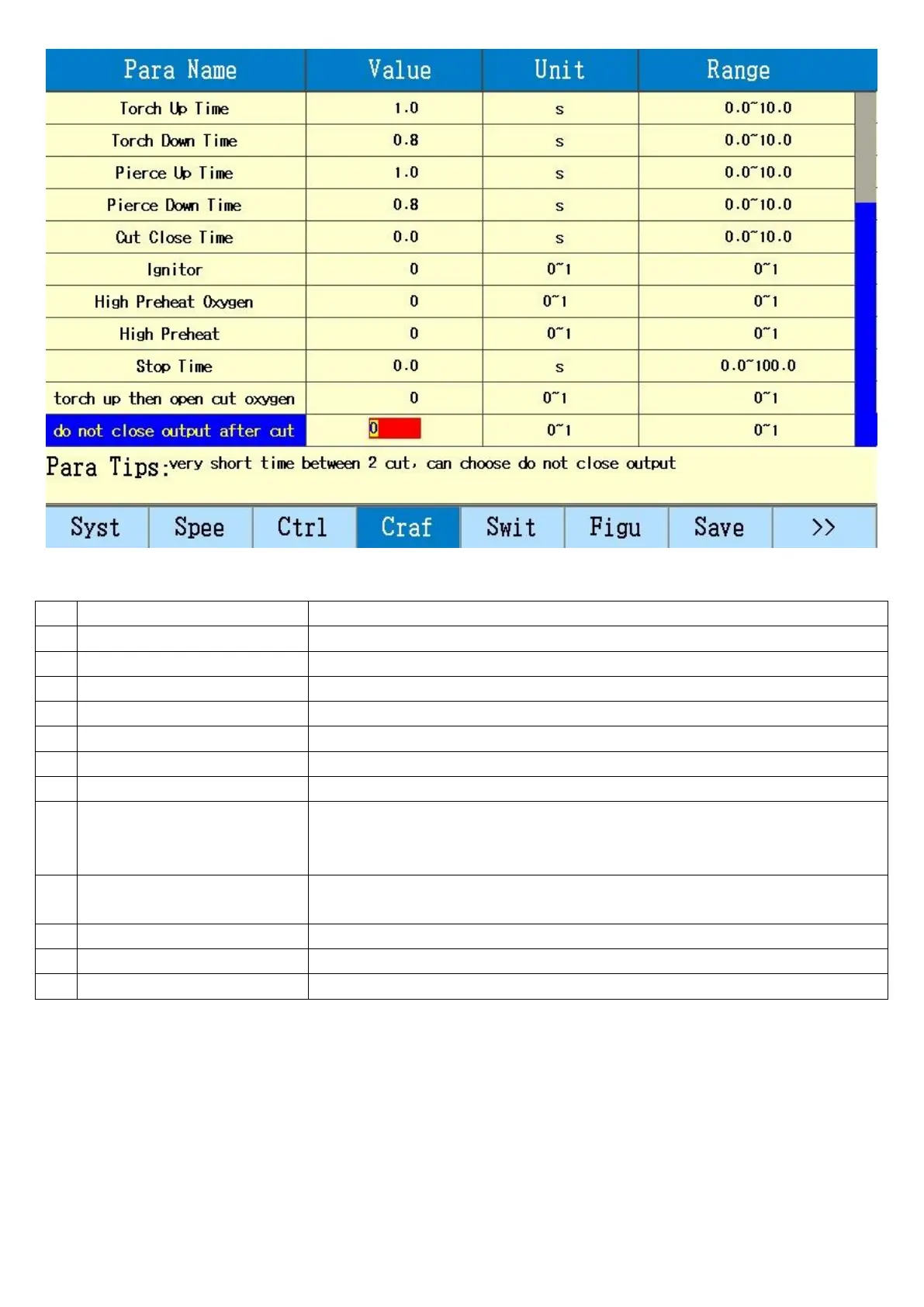

Torch up time after cutting

Torch down time after ignition

Torch up time to pierce height after preheat

Torch down time to cutting height after pierce

Input positive value, after torch stops, cutting output close after a period

of time for eliminate cutting lag angle, then torch move up; input negative

value, close cutting output before torch stops.

Set whether use ignitor, when don’t use, keep preheat between two

cuttings, when use, ignite again for every pierce

Set whether use high-pressure preheat oxygen to assist preheat

Whether keep low preheat oxygen on after preheat and start to cut

Whether keep high preheat oxygen on after preheat and start to cut

Ignition Time: time of torch ignition

Preheat Time: before pierce turn on low preheat and high preheat oxygen

Note: when use auto ignitor

1, when ignite, firstly turn on gas output, then turn on low preheat output, then turn on ignitor output, after

ignition time, turn off ignitor output, keep gas and low preheat output.

2, when pierce (output off), according to setting of “high preheat” to judge whether turn on high preheat. If

choose high preheat, firstly turn on gas output, then turn on low preheat output, then turn on ignitor output,

after ignition, turn off ignitor output, keep gas and low preheat output, turn on high preheat, preheat starts,

after preheat delay, pierce starts; if don’t use high preheat, firstly turn on gas output, then turn on low

Loading...

Loading...