109MS 240, MS 260, MS 260 C

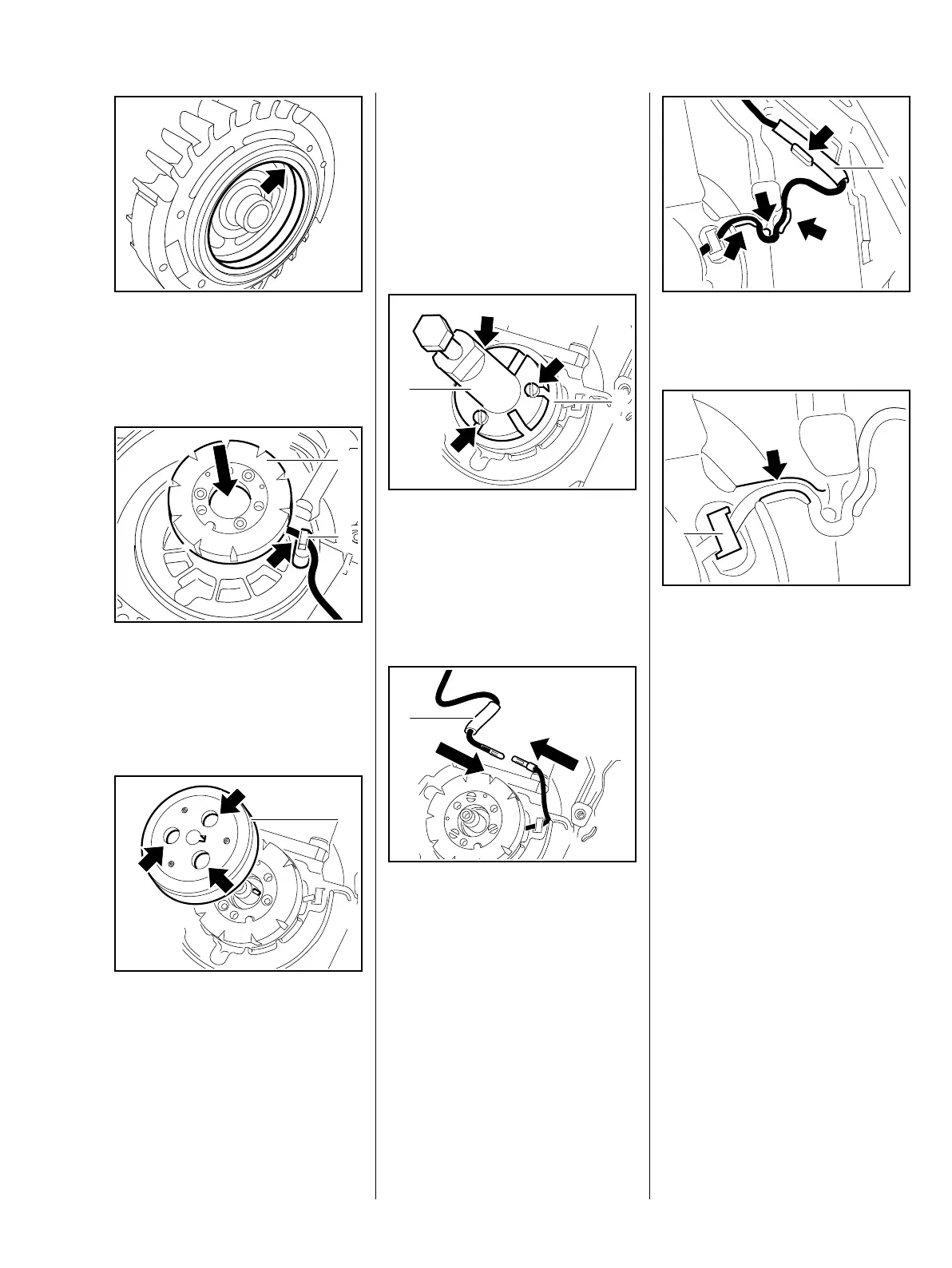

: Inspect the magnet ring (arrow) in

the flywheel for cracks or other

damage. If damage is found,

replace the flywheel.

: Place the generator (1) in

position with the connecting wire

(arrow) facing the crankcase and

push the retainer (2) into its seat

at the same time.

: Push the centering tool (1)

1118 893 3500 onto the

crankshaft so that the slot

engages the Woodruff key – the

generator is now centered.

165RA442 TG

165RA443 TG

1

2

165RA444 TG

1

– Use threadlocking adhesive,

b 17.

– Insert the screws through the

holes (arrows) and tighten them

down firmly.

– Tightening torques, b 3.5

– Remove the centering tool (1).

: If necessary, secure the puller (2)

1107 890 4500 with screws

(arrows) and pull off the centering

tool.

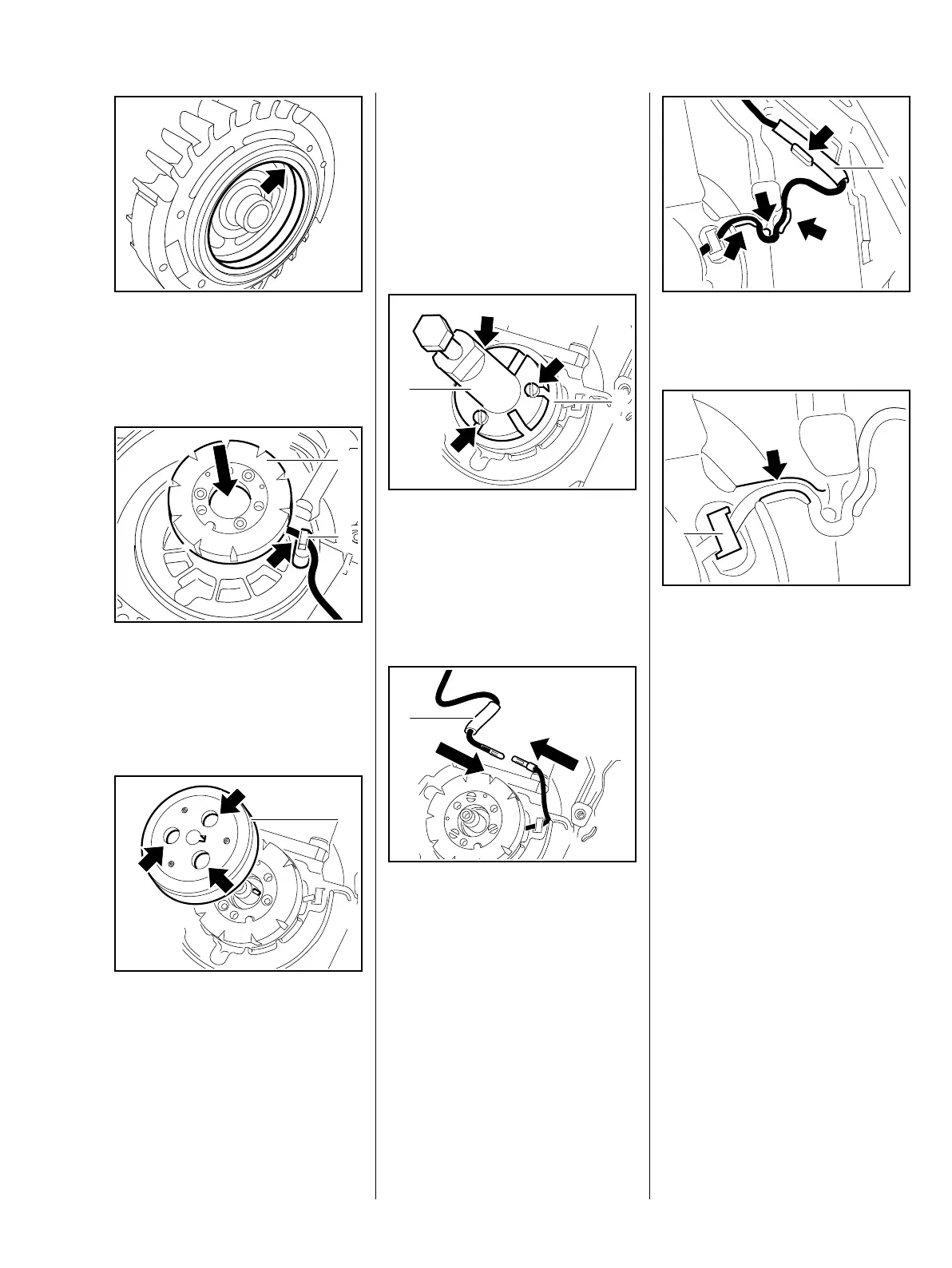

: Reconnect the pin and socket

connector.

– Push the insulating tube (1) over

the connector.

To reduce the risk of a short circuit,

make sure the insulating tube

completely covers the connector.

165RA445 TG

1

2

165RA446 TG

1

: Push the generator wire and

connector (1) into the guides

(arrows) as far as stop.

: The wire must be properly seated

in the guide and must not project

– bond in position if necessary

(arrow).

The retainer (1) must be pushed

fully home.

The flywheel must not touch the

generator wire.

– Reassemble all other parts in the

reverse sequence.

1

165RA447 TG165RA448 TG

1

Loading...

Loading...