87MS 240, MS 260, MS 260 C

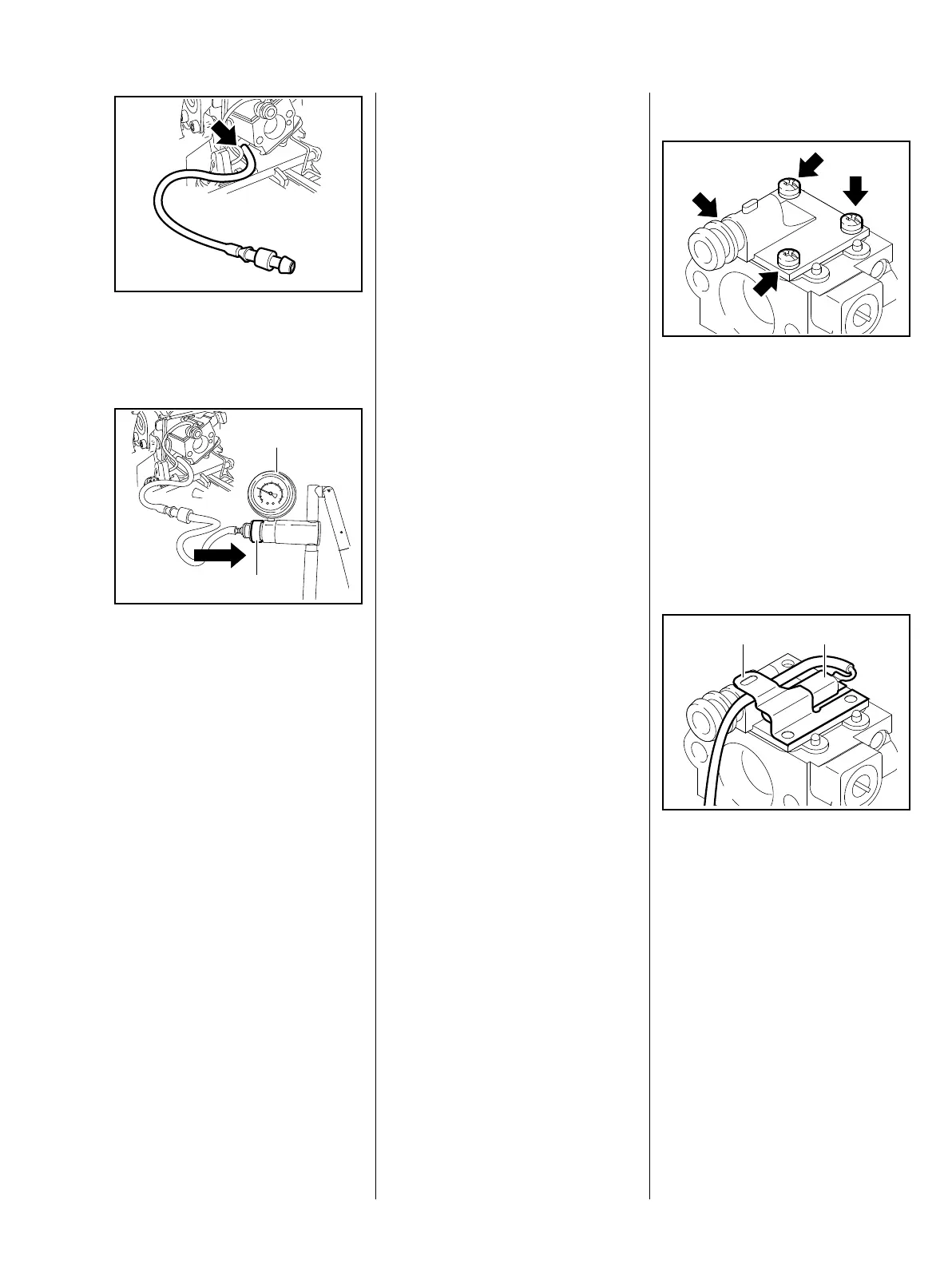

: Push the fuel hose with nipple

onto the carburetor’s fuel stub

(arrow).

– Push the pressure hose of pump

0000 850 1300 on to the nipple.

: Push the ring (1) to the right and

pump air into the carburetor until

the pressure gauge (2) indicates

a pressure of about 0.8 bar

(80 kPa).

165RA337 TG

1

2

165RA338 TG

If this pressure remains constant,

the carburetor is airtight. However, if

it drops, there are three possible

causes:

1. The inlet needle is not sealing

(foreign matter in valve seat,

sealing cone of inlet needle

is damaged or

inlet control lever is sticking).

Remove to clean,

b 14.4.1

2. Metering diaphragm or gasket

damaged, replace if necessary,

b 14.4

3. Pump diaphragm or

gasket damaged, replace

if necessary, b 14.4.3

– After completing the test, push

the ring (1) to the left to vent the

system and then pull the fuel

hose off the carburetor.

– Install the carburetor, b 14.2

– Tightening torques, b 3.5

– Reassemble all other parts in the

reverse sequence.

14.4 Servicing the Carburetor

– Troubleshooting, b 4.6

– Remove the carburetor, b 14.2

– Disconnect the throttle rod,

b 14.6

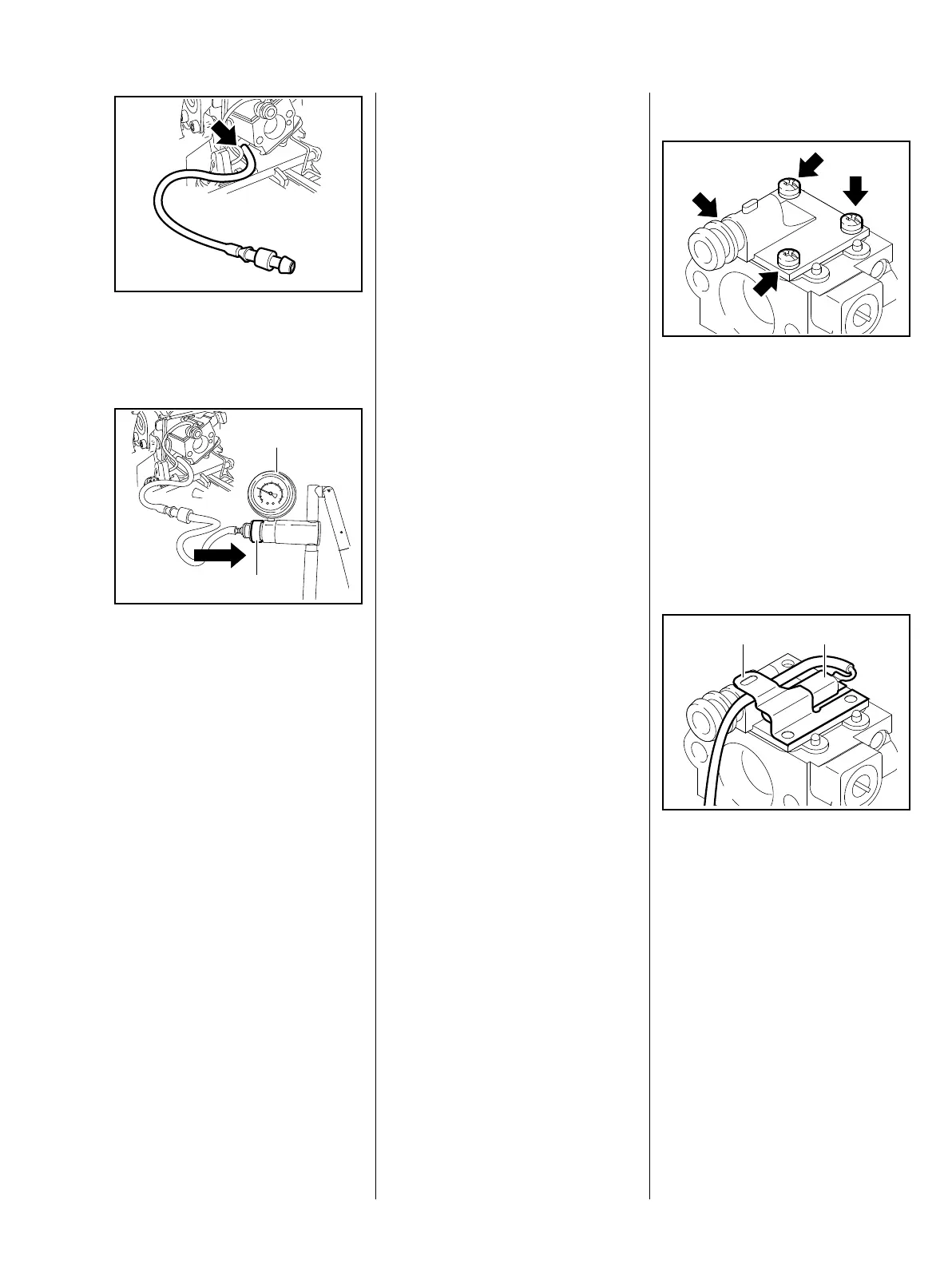

: Take out the screws (arrows).

Versions with handle and

carburetor heating

: Remove the retainer (1) and

thermostatic switch (2).

165RA339 TG

165RA340 TG

1 2

Loading...

Loading...