88 MS 240, MS 260, MS 260 C

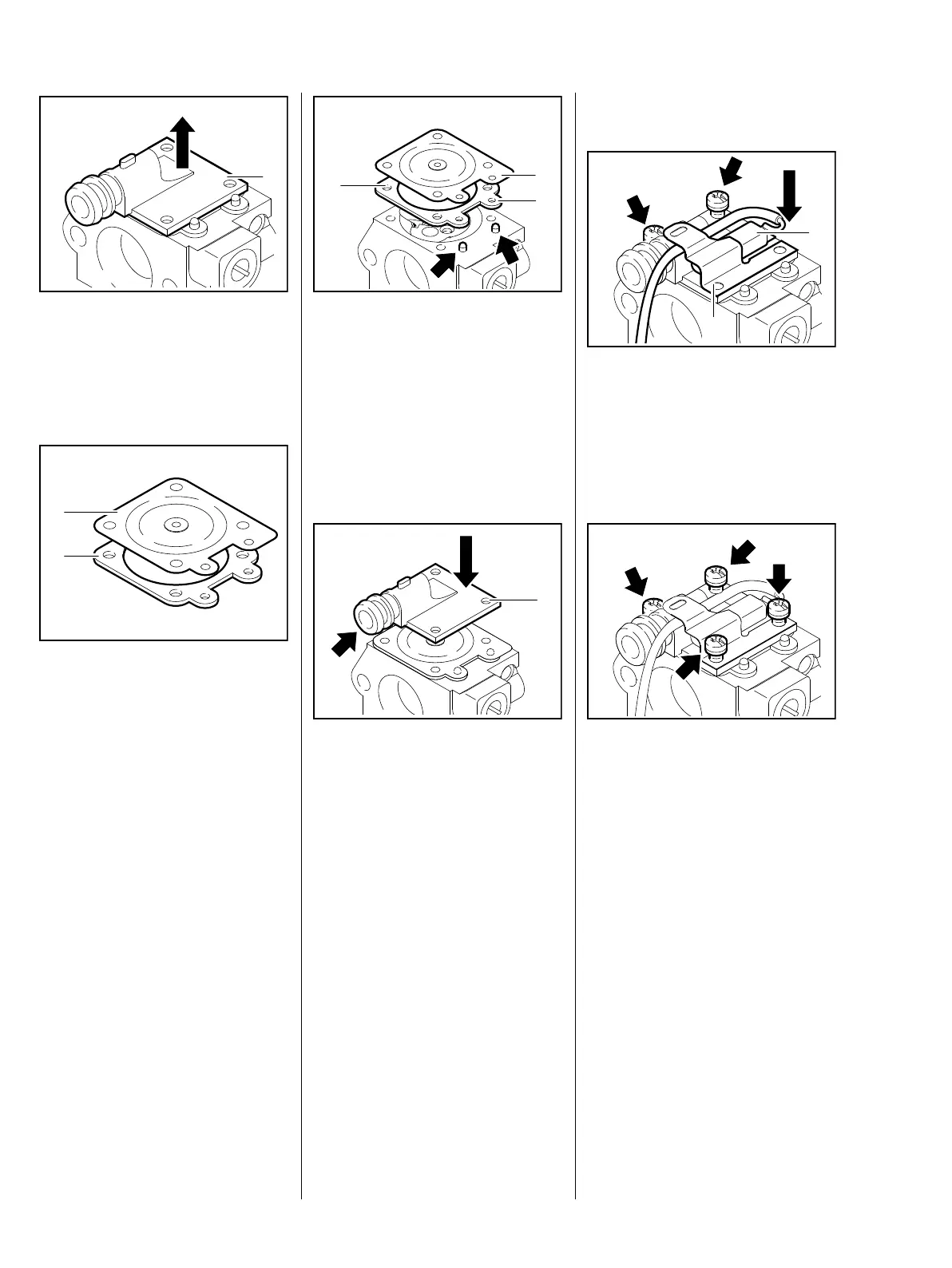

: Remove the end cover (1).

If the gasket and diaphragm are

stuck to the carburetor, remove

them very carefully.

: Carefully separate the metering

diaphragm (1) and gasket (2).

The diaphragm material is

subjected to continuous alternating

stresses and eventually shows

signs of fatigue, i.e. the diaphragm

distorts and swells and has to be

replaced.

– Check the metering diaphragm

(1) for signs of damage and wear.

Install a new gasket.

165RA341 TG

1

1

2

165RA342 TG

– Note installed positions of

metering diaphragm (2) and

gasket (1).

: Place the gasket (1) and

metering diaphragm (2) on the

pegs (arrows) and check that the

tabs (3) are at the same side as

the adjusting screws.

– Position the end cover (1) so that

the stub (arrow) points towards

the air filter.

: Fit the end cover (1) carefully –

the holes must be in alignment.

165RA076 TG

1

2

3

165RA343 TG

1

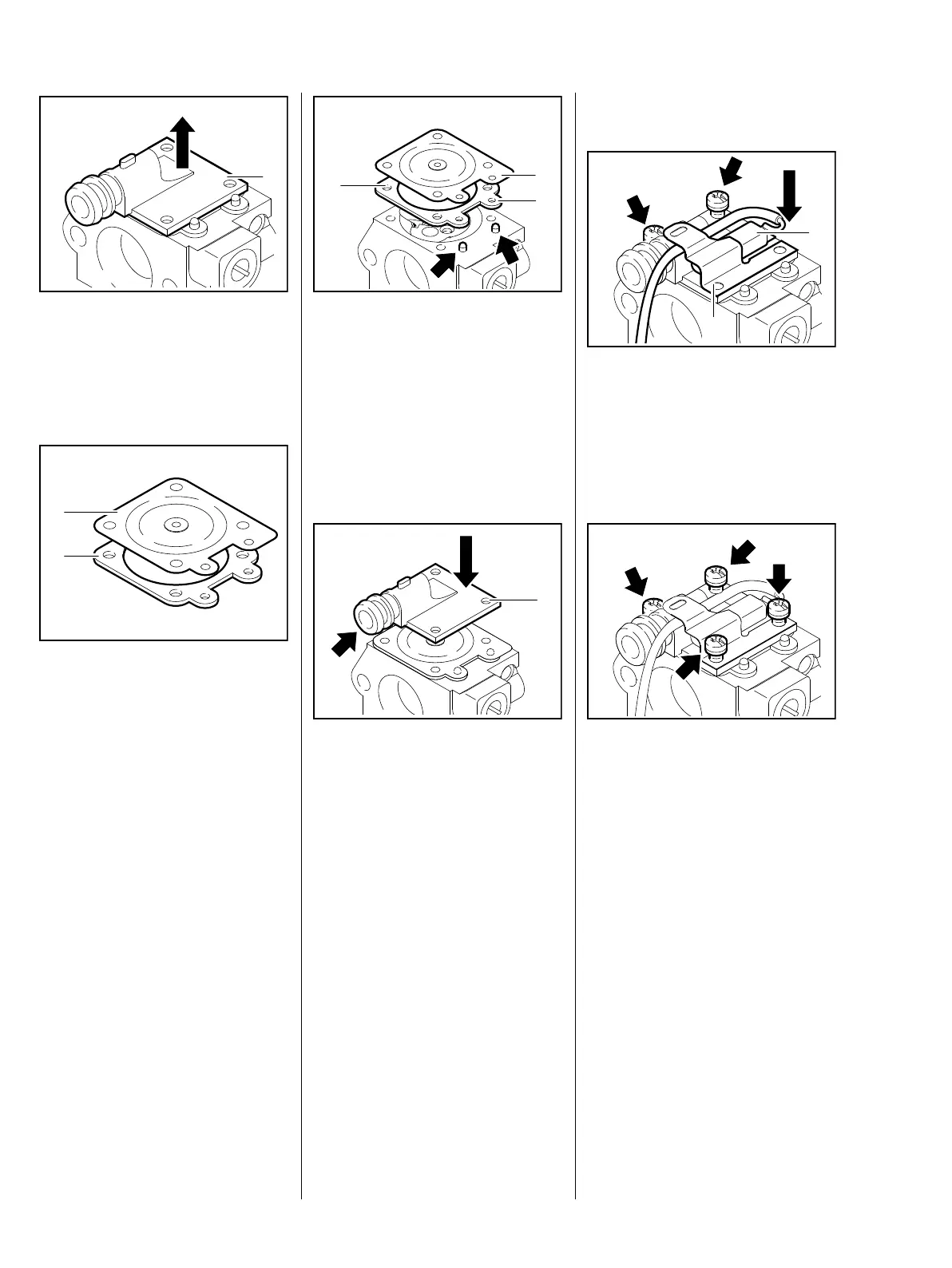

Versions with handle and

carburetor heating

: Insert two screws (arrows) to hold

the end cover, gasket and

metering diaphragm in position.

: Fit the thermostatic switch (1)

and retainer (2).

: Fit the screws (arrows).

– Check position of diaphragm and

gasket, then tighten down all

screws firmly in a crosswise

pattern..

– Reassemble all other parts in the

reverse sequence.

165RA344 TG

2

1

165RA229 TG

Loading...

Loading...