11

BASIC SETUP

Follow the Site Preparation Guide to ensure that your facility is effectively and safely prepared for printer

installation. Do not proceed with the following sections until the “Unpacking the Printer” section of the Site

Preparation Guide has been completed. When installation is complete, perform the following setup tasks.

• Verify that the startup materials have been removed from the oven chamber. If not, remove these

items. See “Additional Components - Startup Materials” on page 10 for details on the startup

materials.

• Open the top cover and ensure that the orange clip has been removed from the X belt, and the

orange tie wrap has been removed from the X motor. If not, remove the orange clip and/or orange tie

wrap securing these components.

STABILIZING THE PRINTER

To stabilize the printer:

1. Roll the printer to its desired operating location and verify that minimum space requirements

have been met.

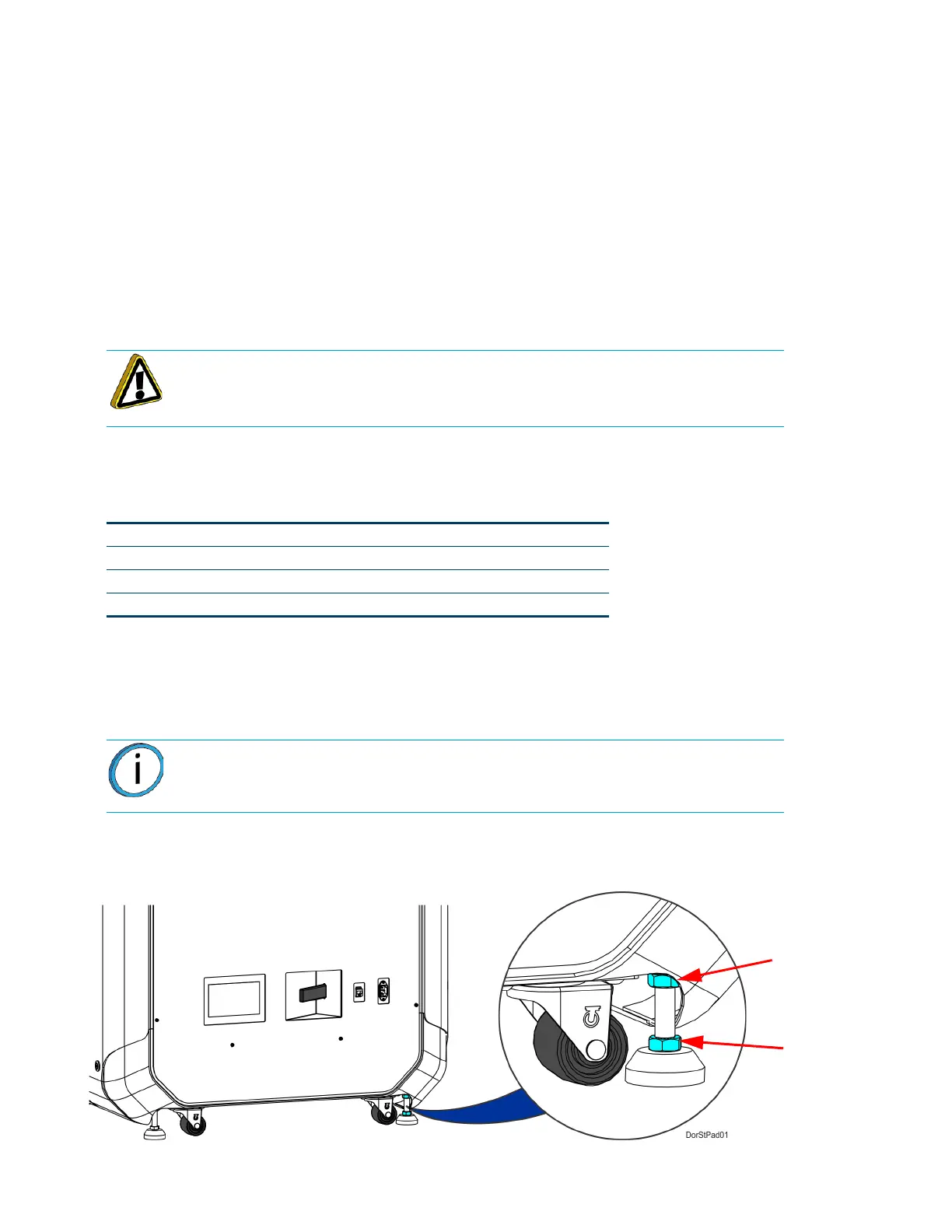

2. Thread the stability pad jackscrew downward until the stability pad makes contact with the floor

(see Figure 2-5).

3. Turn the jackscrew an additional 1-2 turns downward and set the locknut firmly against the lower

frame member (see Figure 2-5).

4. Repeat step 2 and step 3 to set all remaining stability pads.

Figure 2-5: Stability Pad Jackscrew Adjustment

Caution: The stability pads are used to stabilize the printer after it has been

moved to its desired operating location. The stability pads must be set prior to

printer operation.

Side Clearance Minimum 4 inches (10.16 cm) on each side

Rear Clearance Minimum 6 inches (15.24 cm)

Front Clearance Minimum 20 inches (50.80 cm)

Overhead Clearance Minimum 20 inches (50.80 cm)

Note: Ideally, each caster wheel will remain in slight contact with the floor and

using minimal force, be able to be rotated.

Loading...

Loading...