SS100 Build Manual (Export Edition) Rev 10 November 2013

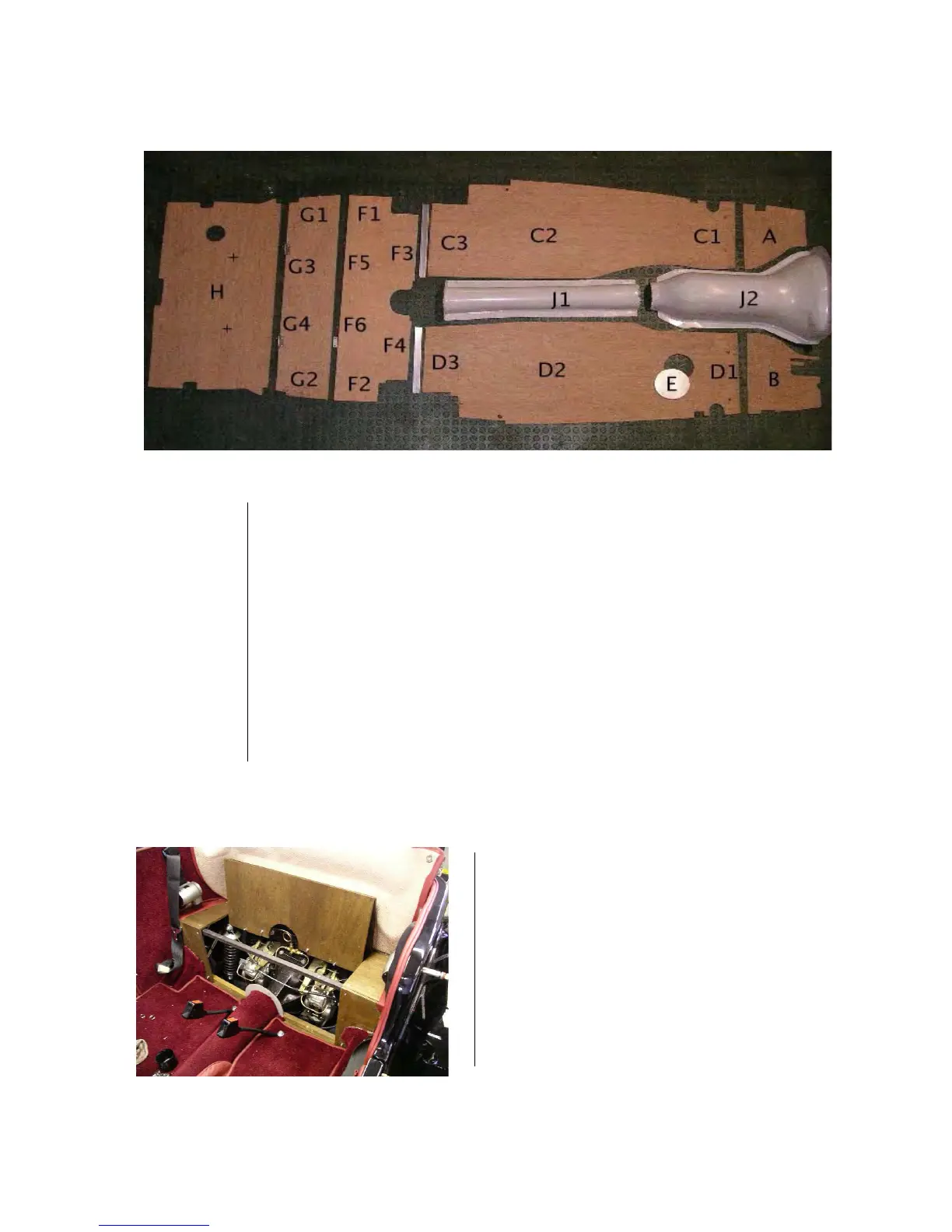

Figure 15 – Floorboard Fitting Kit

2no. M6 x 20mm countersunk slot screws – drill 5mm hole & tap M6

2no. M6 x 20mm countersunk slot screws – drill 5mm hole & tap M6

4no. 5/16” x 1 1/4” UNF socket head cap screws for seat runners – drill 7mm & tap

5/16”unf

2no. M6 claw nuts with screws – drill 6.5mm hole and hammer in nut on top surface. Screw

angle brackets to under side of board into claw nuts

1no. M6 claw nut & screw and 2no. small wood screws for clutch fluid filler cover

2no. self tapping countersunk posi drive screws – screw into metalwork

2no. M5 x 20mm machine screws screws – drill 4mm holes & tap M5 into angle

4no. small countersunk woodscrews for fixing hinges onto section ‘G’

2no. self tapping countersunk posi drive screws – screw into metalwork

4no. small countersunk woodscrews for fixing hinges onto section ‘H’

2no. 7/16” unf bolts (‘+’ into the captive nuts on chassis)

16no. countersunk slot wood screws with cup washers for tunnels

- Fixings supplied in Nut & Bolt kit. All other fixings supplied separately with this kit.

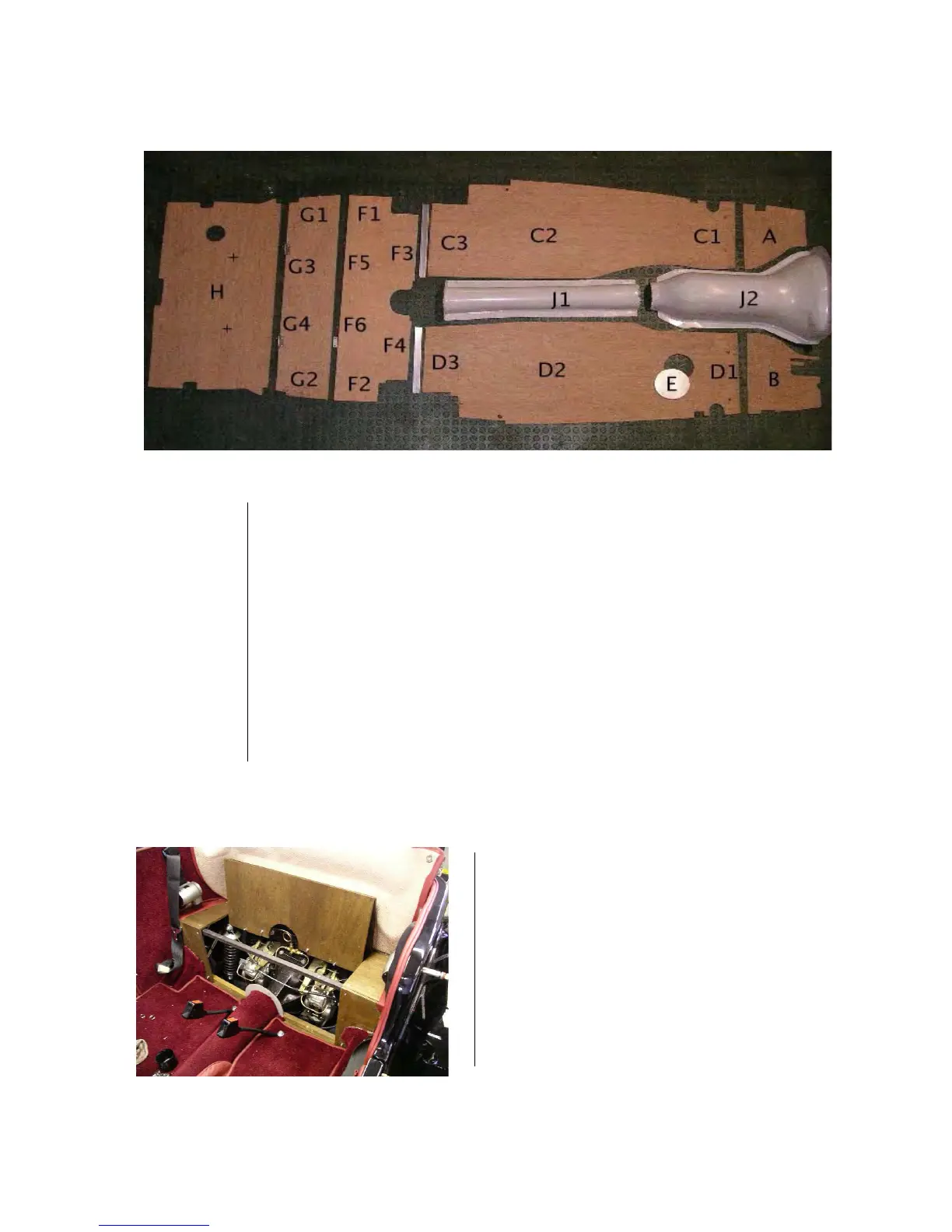

Picture to left

This shows an example of how the rear

floorboards can be fitted with a piano hinge

format allowing great access to the rear brakes

and suspension.

These panels can also be made removable with

a hidden tool tray under the top panel that can

have a hinged lid cut in.

Loading...

Loading...