Istruction Manual for Operation and Maintenance SPX-960:

2.4.4 PREVENTION OF FIRE AND EXPLO-

SIONS

Fuel and oil are fl ammable and may cause serious injuries. For

this reason comply with the instructions below.

• Do not operate the machine in areas where there is a risk

of explosion and fi re (power stations, refi neries, etc.).

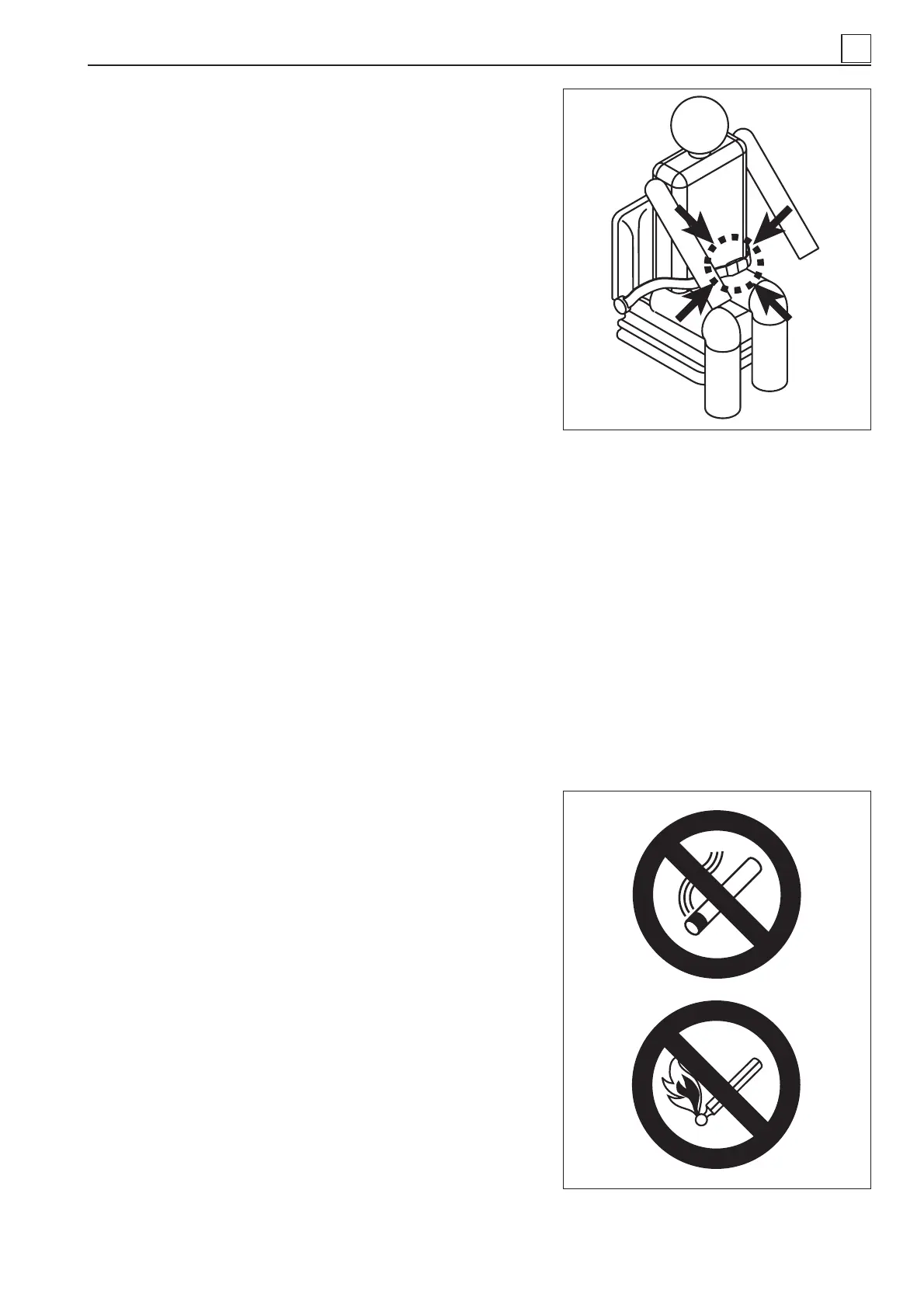

• Do not smoke and do not use free fl ames near fl ammable

fl uids (Fig. 9).

• Switch the engine off and do not smoke during fuel re-

fi lls.

• Tighten all the caps of the fuel and oil tanks.

• Top up the oil or fuel in properly ventilated areas.

• Wipe any spilled fl uid clean.

• Do not leave the machine unattended while fi lling it with oil

or fuel.

• Inspect the entire fuel system to identify possible leaks,

infi ltrations or damage in the fuel hoses. Clean, repair or replace whenever it is necessary.

• Inspect the entire fuel system to identify possible leaks or infi ltrations including hoses, fi lters and injec-

tion system. Clean or repair whenever it is necessary.

• Do not drop fuel on superheated surfaces or on the parts of the electrical system.

• Keep oil and fuel in a pre-defi ned place where good ventilation is guaranteed and access to unautho-

rized personnel is prohibited.

• Before grinding or welding operations on the frame, move fl ammable material to a safe place.

• Use an infl ammable lubricant to wash parts requiring it.

• Diesel fuel and gasoline may ignite: do not use these fl uids.

• For greater safety at work move cloths soaked with grease and other fl ammable material into a safe

container.

• Do not weld or oxy-fuel cut pipelines or piping which contain fl ammable fl uids.

• Do not leave lighters or gas cylinders around the operator’s cabin.

• Remove dry leaves, paper, wood dust or other fl ammable

material that may have stacked or deposited on the engine,

manifold, exhaust muffl er, air fi lter or battery.

• Do not forget that short circuit in the electrical system may

cause fi re. Check the electrical cables on a daily basis to

make sure that no part of the electrical insulation is loosened

or damaged.

• Tighten slackened connectors or cable clamps.

• Repair or replace damaged, pinched or broken cables.

• Do not operate the machine if voltage is higher than requi-

red.

• Check that all the clamps in the hoses and pipes of the

hydraulic system, in the covers and in the vibration dumpers

are secured in place.

• If they are loosened, they may shake during operation and

hit the other parts. This may damage the hoses, consequen-

tly leading to high pressure oil spillage which may eventually

cause fi re and serious accidents.

• Check for oil leaks on a daily basis. Whenever one is iden-

tifi ed, repair it immediately.

Fig. 9

2

Fig. 8

2-13

SAFETY RULES

Loading...

Loading...