Istruction Manual for Operation and Maintenance SPX-960:

The wire rope supervisor and tester must be qualifi ed to understand the causes of possible breakage or

damage to the rope: he must be able to understand if the rope is in good operating condition or if it needs

to be replaced.

The wire rope supervisor is also responsible for the following:

- he assists wire rope installation after making sure that it has been lubricated properly and is suitable for

the application on which it is installed;

- he records the wire rope specifi cations, the installation date and the max. number of admissible wires in

the equipment inspection book;

- he trains personnel on wire rope installation;

- he trains machine operators on start-up operations (low speed, reduced loads, no jerking);

- he ensures that the wire rope is suitable with the winding drum after one week from installation and

checks the anchoring devices and end locks;

- he checks for possible problems after one month from installation;

- he checks the wire rope conditions periodically, i.e. every three months, or at shorter intervals depending

on the rope conditions;

- he fi xes anchoring devices, if and as needed;

- he services any equipment malfunctioning such as no engagement of the anti-two block switches, wire

rope release from the drums or pulleys.

WARNING

The wire ropes must be replaced every 1500 hours. funi.

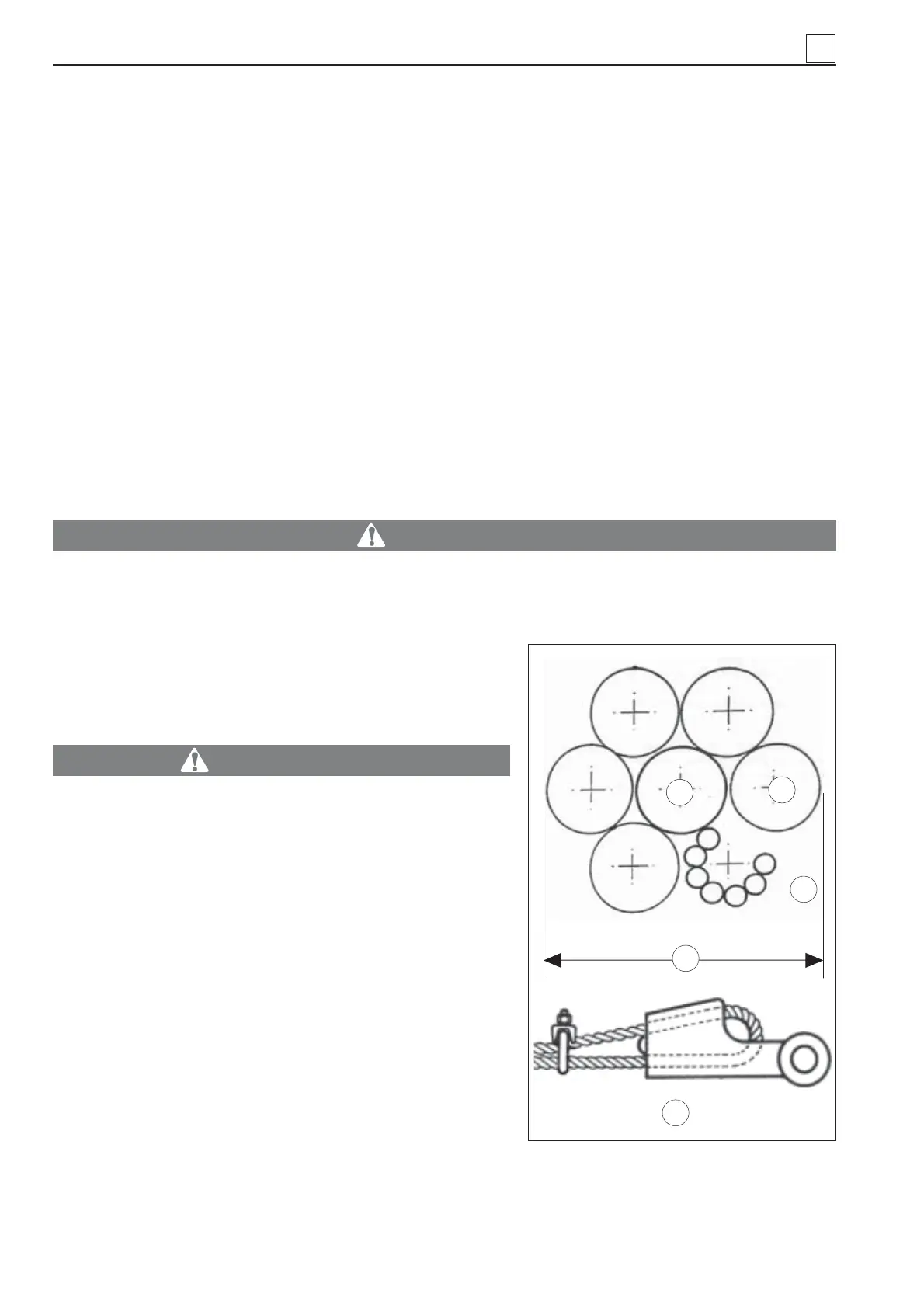

Small grooves cause wire rope deformations and excessive contact between the rope elements (strands

and core - Fig. 54): this may jeopardize wire rope performance

and duration. The wire rope duration is also affected by groo-

ve wear. For instance, if the groove is excessively scored or

deformed, the wire rope is more likely to get worn.

DANGER

The wire rope is wound on parts which are specifi cally

sized according to the rope diameter. For this reason, it

is not recommended (due to more rapid wear) and it is

dangerous to use different wire rope diameters from those

indicated by the manufacturer.

5.2.6 WIRE ROPE MAINTENANCE

Constant maintenance and periodic checks guarantee proper

preservation of the wire ropes. Other precautions for wire rope

preservation are:

1) do not put the rope on muddy or dusty soil;

2) handle the wire rope with gloves;

3) do not clean the wire ropes with petrol or other solvents:

these fl uids penetrate into the rope and may damage the

core, because they remove the natural oils inside the wire

rope;

Fig. 54

1) Wire rope core. - 2) Wire rope strand. - 3)

Wire rope. - 4) Wire rope diameter. 5) Wire

rope terminal clamp.

1

2

3

4

5

5

5-8

MAINTENANCE

Loading...

Loading...