Istruction Manual for Operation and Maintenance SPX-960:

32) Fuse-holder blocks

33) Visio monitor (OPTIONAL).

34) Anti-tipping system bypass key

35) Anti-tipping system power switch

36) White light - anti-tipping electrical system error

37) Anti-tipping light alert depending on lifting capacity

41) Battery on/off key on engine hood left-hand side (A battery ON - B battery OFF)

43) Electronic control unit

45) Safety lever

46) PC plug for CPU

4.3.2 CONTROLS AND CONTROL DEVICES

Below is a description of the controls and control devices installed in the operator control station.

WARNING

It is essential to get familiar with the machine controls and

fi ne movements before starting operation.

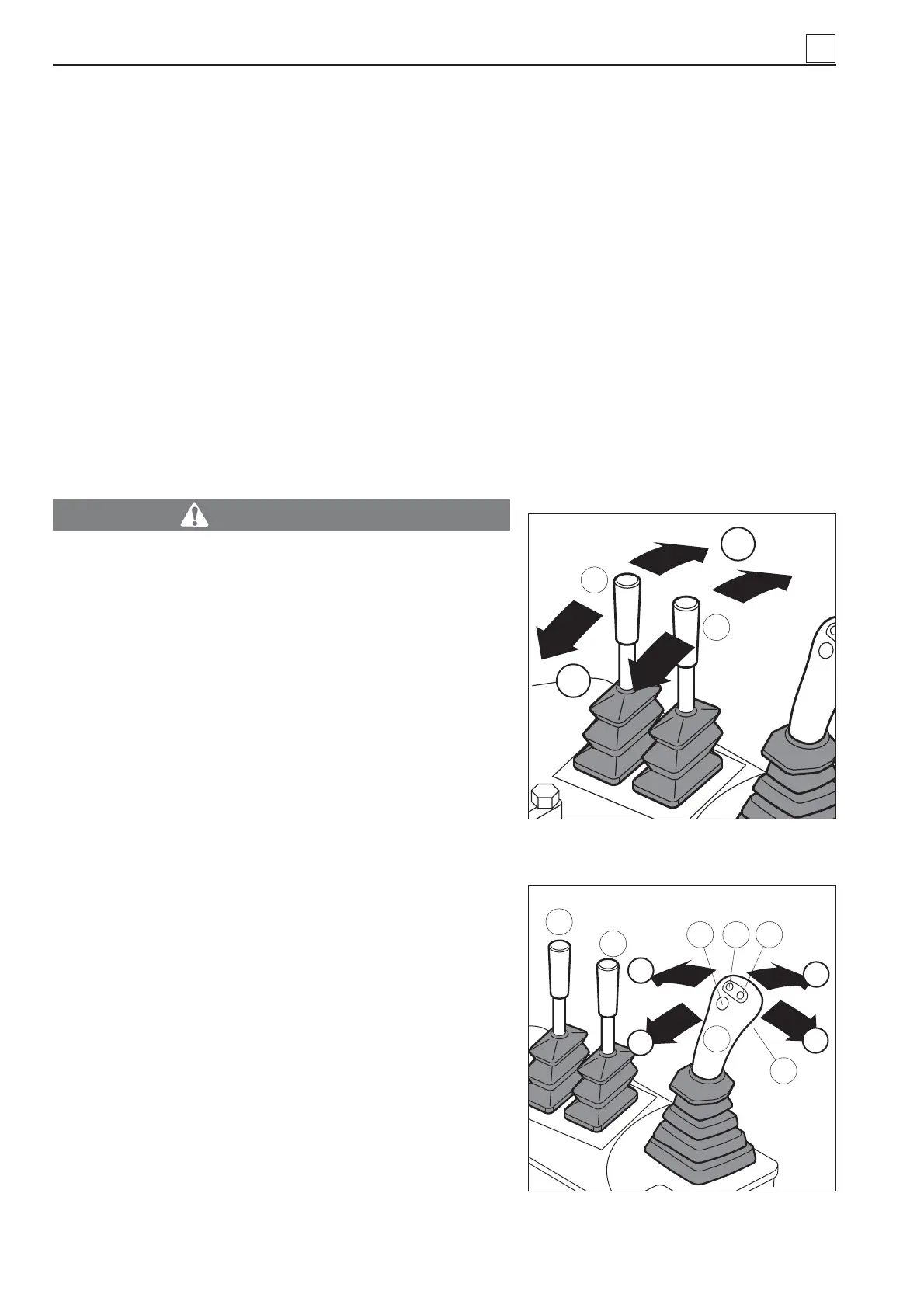

1) Left-hand drive lever (Fig. 22).

2) Right-hand drive lever (Fig. 22).

Levers 1) and 2) are used for fi ne steering corrections of

the track control.

LEVER 1 (Fig. 22):

- push lever 1 to “A”: the left-hand track moves forward

and causes the machine to turn right. When the lever is

released, it automatically goes back to neutral position;

- pull lever 1 to “B”: the left-hand track moves backward

and causes the machine to turn left. When the lever is

released, it automatically goes back to neutral position.

LEVER 2 (Fig. 22):

- push lever 2 to “A”: the right-hand track moves forward

and causes the machine to turn left. When the lever is

released, it automatically goes back to neutral position;

- pull lever 2 to “B”: the right-hand track moves backward

and causes the machine to turn right. When the lever is

released, it automatically goes back to neutral position.

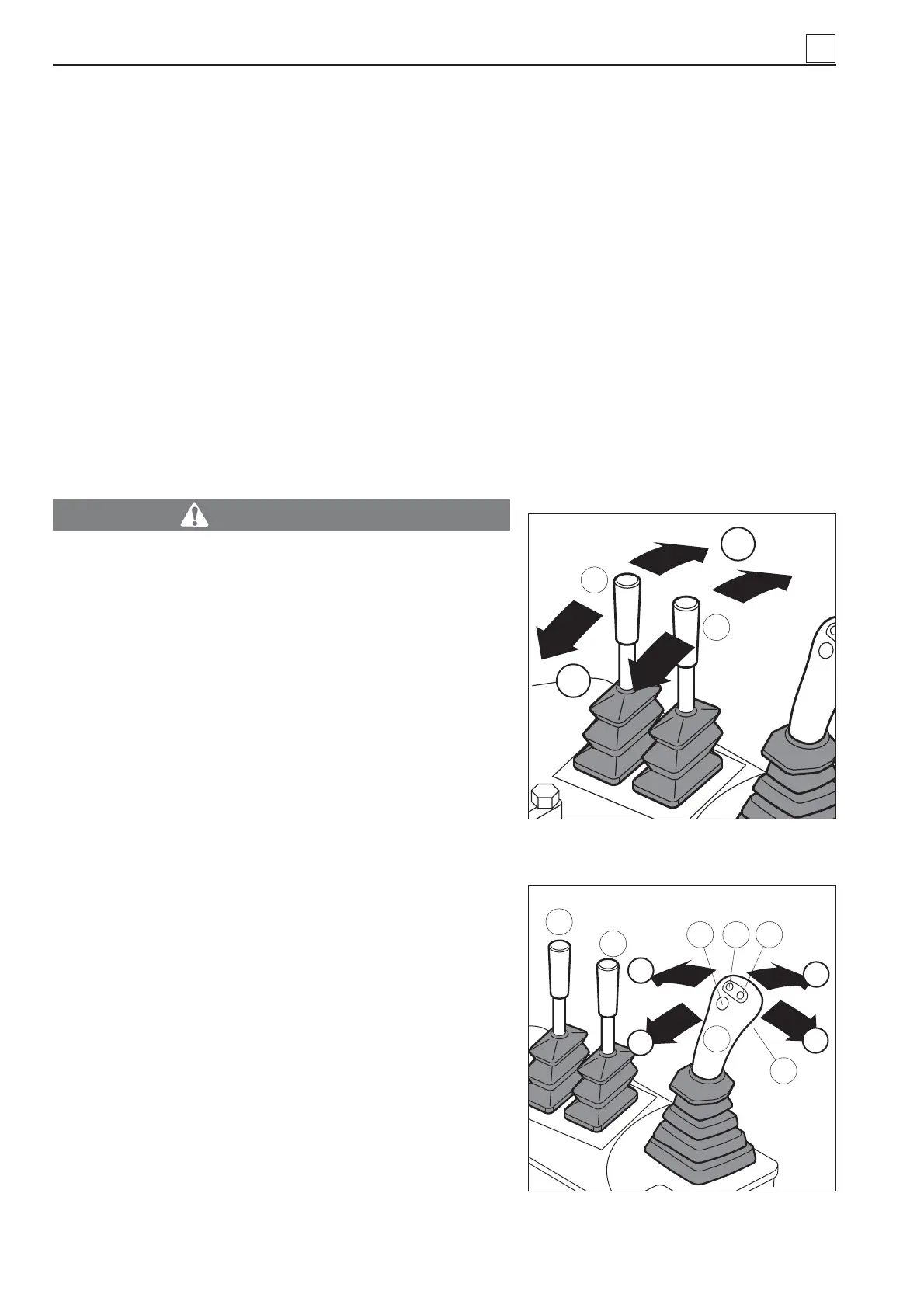

3) Multiple function joystick for drive control (Fig. 23). The

machine direction (i.e. back-forward, right-left and interme-

diate positions) and progressive speed are dependant on

the type of movement controlled by the joystick. The four

buttons built in the joystick are used to select the number

of engine rpm (preliminarily set).

- Push the joystick to “A” to let the pipe layer move for-

ward.

Fig. 23

1

2

C

A

B

E

7

654

3

A

1

2

Fig. 22

B

4

4-8

MACHINE OPERATION

Loading...

Loading...