Istruction Manual for Operation and Maintenance SPX-960:

5.7.2 FUSES

The fuses are installed on the control panel (32 in Fig. 66):

they protect the entire electrical system. Refer to the electrical

diagram supplied separately for the different circuits protected

by the fuses.

To replace blown fuses, extract the fuse that has blown off and

replace it with a new one.

When a fuse blows off, replace it immediately. If the same

fuse blows again, ask competent and authorized personnel

to check it.

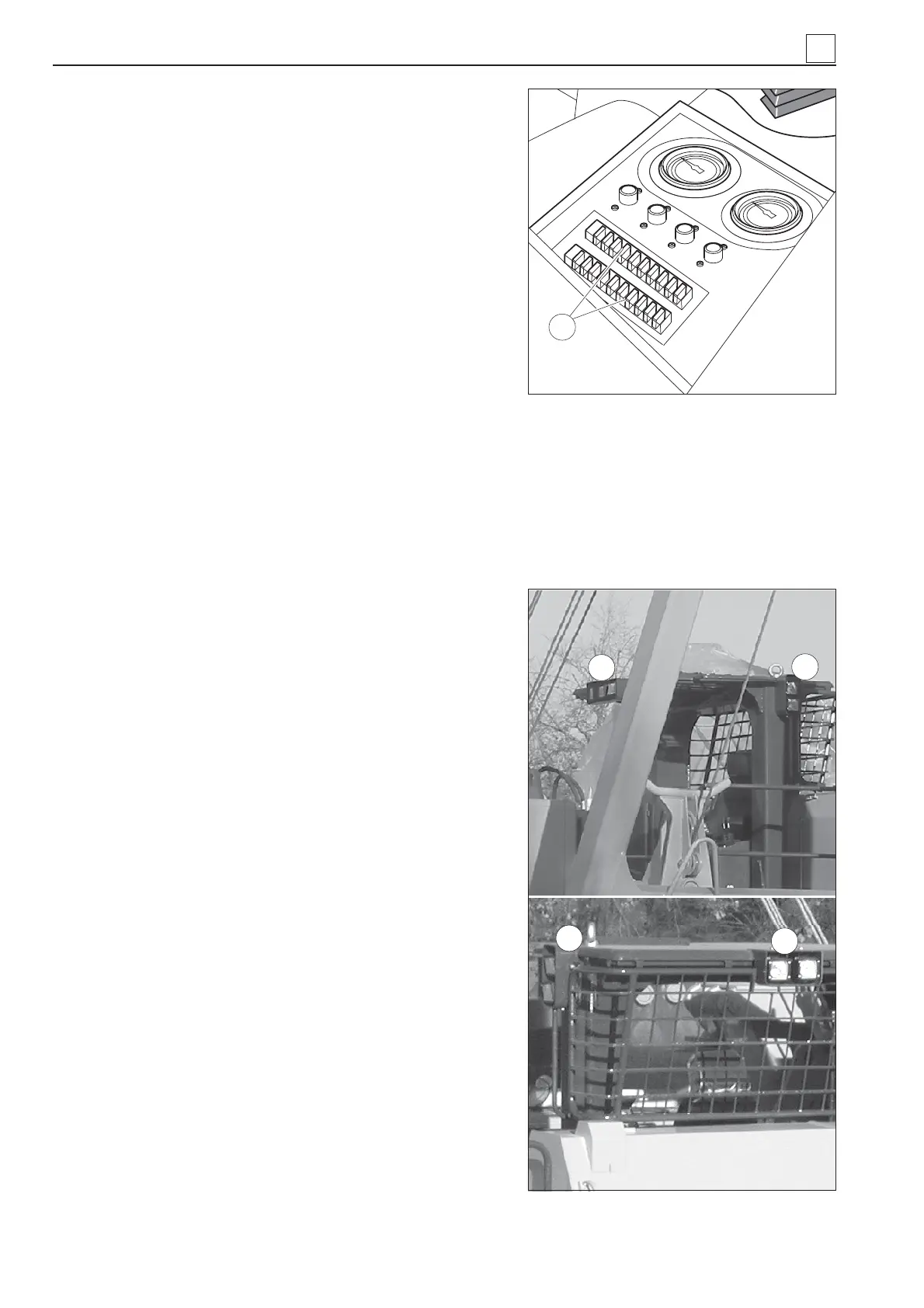

5.7.3 LIGHTS

The machine is supplied with lights (1, 2 & 3 in Fig. 67) on

all three sides of the Rops-Fops structure and on the engine

hood. For proper lighting these lights must always be in good

operating condition.

Replace blown bulbs with new ones of the same type.

5.8 SCHEDULED MAINTENANCE

AFTER THE FIRST 8 HOURS OF OPERATION

Check the machine and its units/equipment. Make sure that:

- all the bolts are tightened properly;

- none of the parts in the hydraulic system presents oil lea-

ks;

- moving or rotating parts are lubricated properly;

- only the lubricants recommended by the Manufacturer are

used; genuine spare parts only are used.

Before operating the machine again, make sure that no oil has

leaked to the ground. If this is the case, DO NOT OPERATE

the machine and locate the oil leak.

Possible causes for oil leaks are the following:

- damaged gear units;

- damaged hydraulic oil reservoir;

- damaged components or piping of the hydraulic system.

5

Fig. 67

1

2

2

3

Fig. 66

32

5-16

MAINTENANCE

Loading...

Loading...