Istruction Manual for Operation and Maintenance SPX-960:

WARNING

After fi nding out the extent of the damage, contact an Authorized Service Center.

Periodically repeat the following mandatory checks:

- check and change the oil in the hydraulic system; lubricate and grease every point requiring it following

the instructions;

- check the machine and its equipment for wear;

- make sure that there are no leaks in the hydraulic system and the hydraulic drive gears are in good

operating condition.

EVERY 8 HOURS OF OPERATION (daily)

- Grease the hinges of the counterweight moving parts.

- Grease the hinges of the side boom.

- Grease the hinges of the hook and boom blocks.

- Grease each point supplied with a greasing nipple.

- Check the oil level in the engine.

EVERY 50 HOURS OF OPERATION

- Check the engine oil level.

- Check the level of the engine cooling water.

- Check the electrolyte level in the batteries.

- Check the level in the hydraulic system.

- Check and, if necessary, tighten all the bolts and screws.

- Check for any worn parts and replace them.

- Paint dented or damaged areas with rust-preventing chemicals.

- Grease each point requiring it.

- Clean the engine air fi lter.

- Clean the radiator fi ns.

OGNI 250 ORE DI SERVIZIO O 6 MESI

- sostituzione olio motore e fi ltro.

EVERY 300 HOURS OF OPERATION

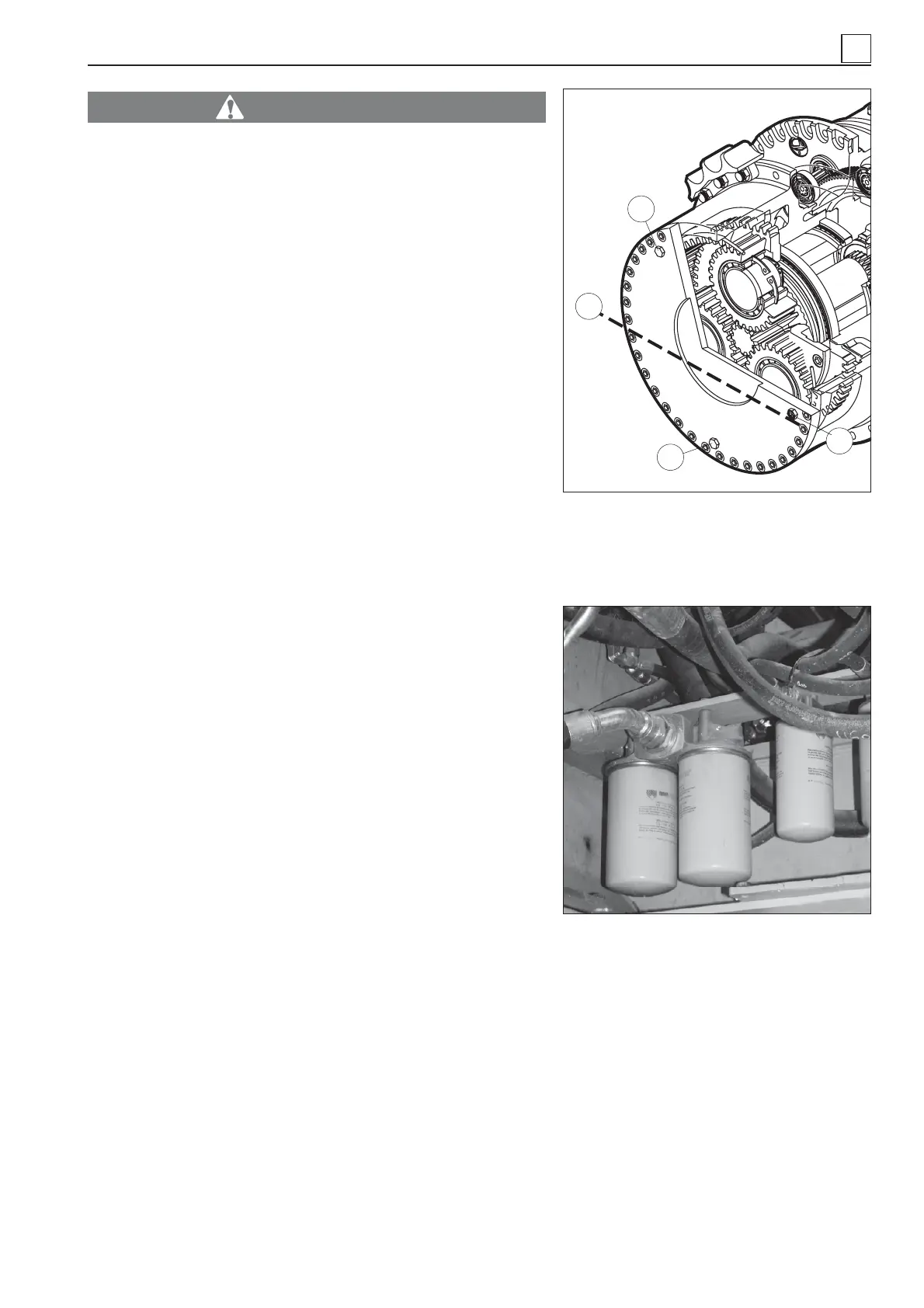

- Check the oil level in the end gears of the tracks (Fig. 68).

- Check the fan alternator belt for tensioning.

- Clean the fuel pump fi lter.

- Check the level in the hydraulic system.

EVERY 600 HOURS OF OPERATION

- Change the oil in the hydraulic system.

- Change the oil fi lters in the hydraulic system.

- Change the oil level in the end gears of the tracks.

- Change the oil in the coupler.

- Replace the engine oil fi lter.

- Replace the fi lter in the engine cooling system.

Fig. 68

1) Oil fi ll plug. - 2) Max. level plug. - 3) Max.

oil level line. - 4) Oil drain plug.

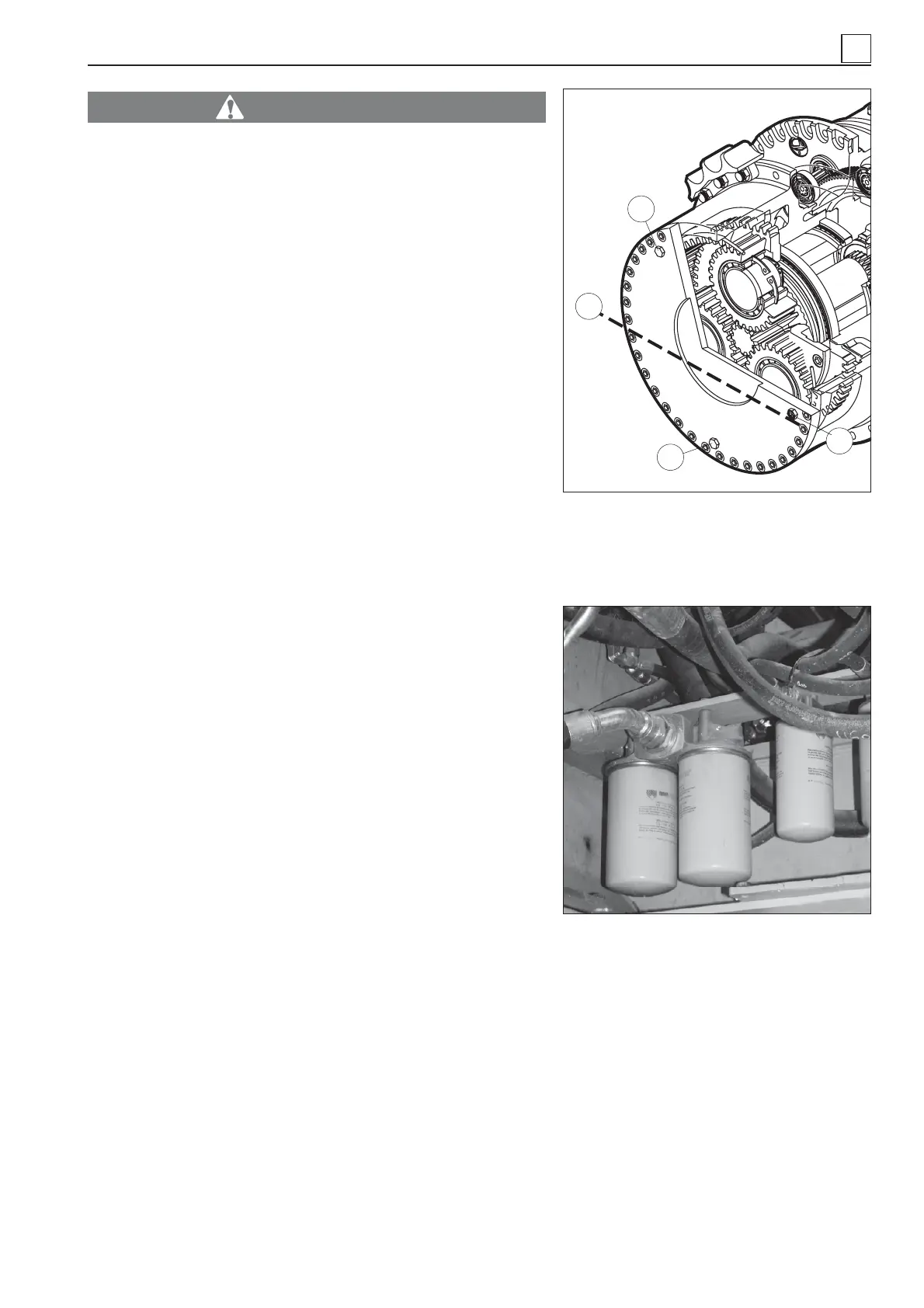

Fig. 69 - Hydraulic system oil fi lters

(access to the fi lters is gained from the

trap door under the machine).

4

3

1

2

5

5-17

MAINTENANCE

Loading...

Loading...